Blade mounting

A rotor blade, on-site installation technology, applied in the installation/support of wind turbine configuration, wind turbine assembly, engine function, etc., can solve the problems of bulkiness, instability and time-consuming, and achieve low investment cost and cost-effective Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

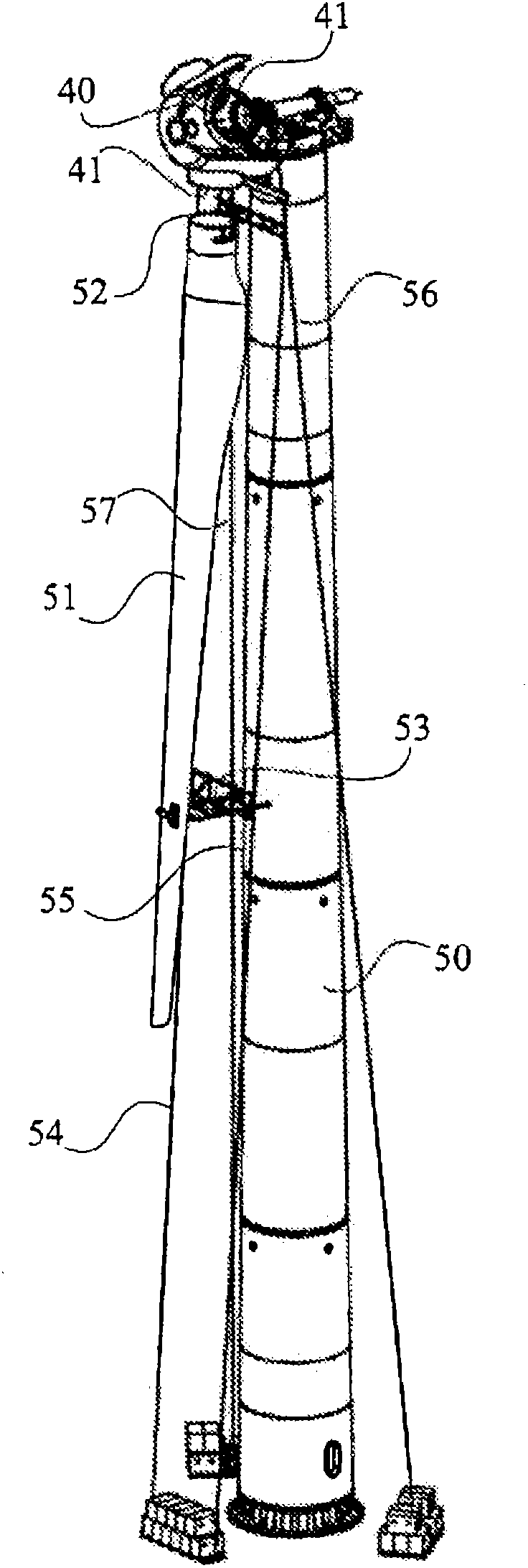

[0022] figure 1 An overview map of wind power equipment. The rotor blade 51 is lifted to the rotor hub 40 at the upper part of the tower 50 so as to be fitted with its rotor blade connection 52 onto the flange 41 of the rotor hub 40 through which the rotor hub 40 passes through the hub flange (in figure 2 shown in ) to the spindle.

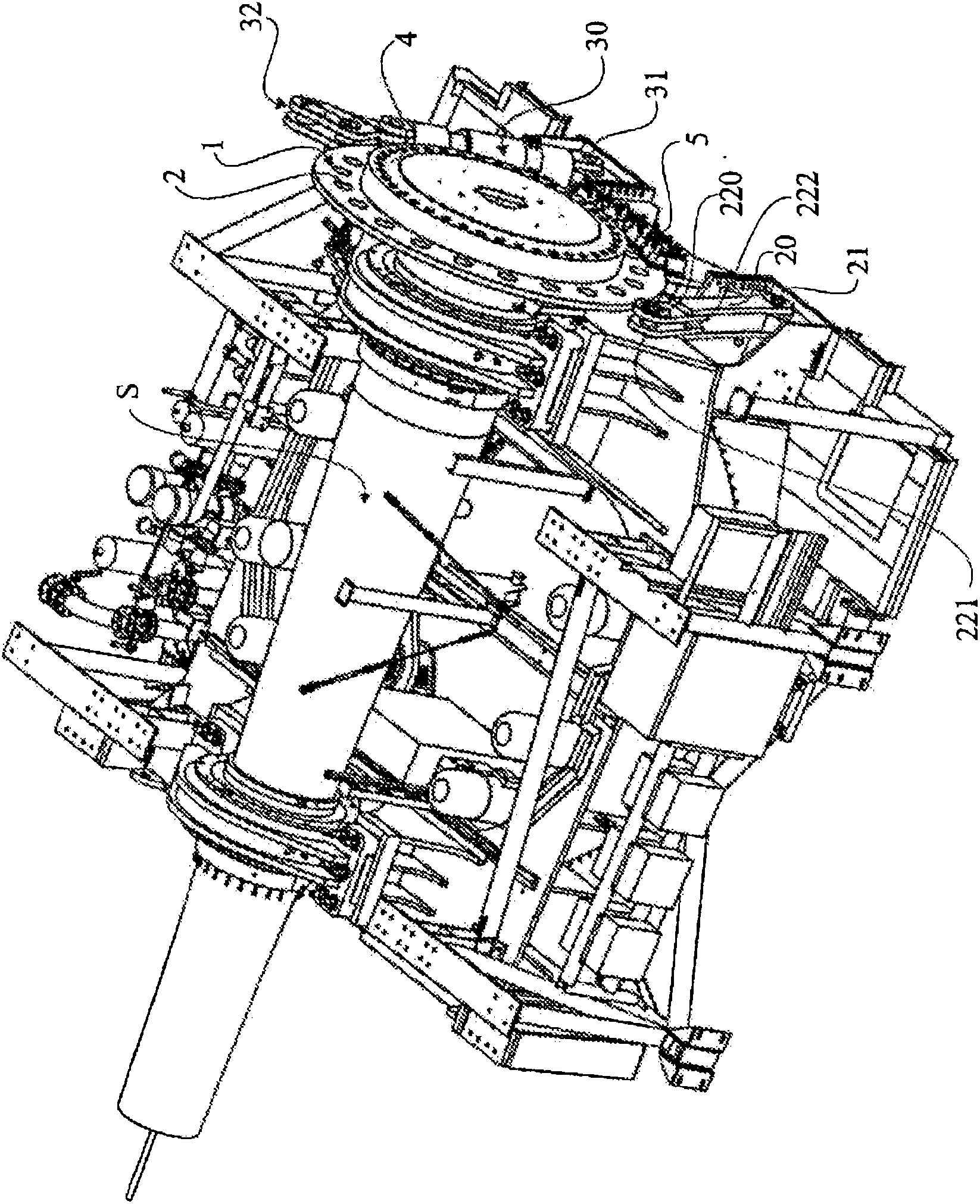

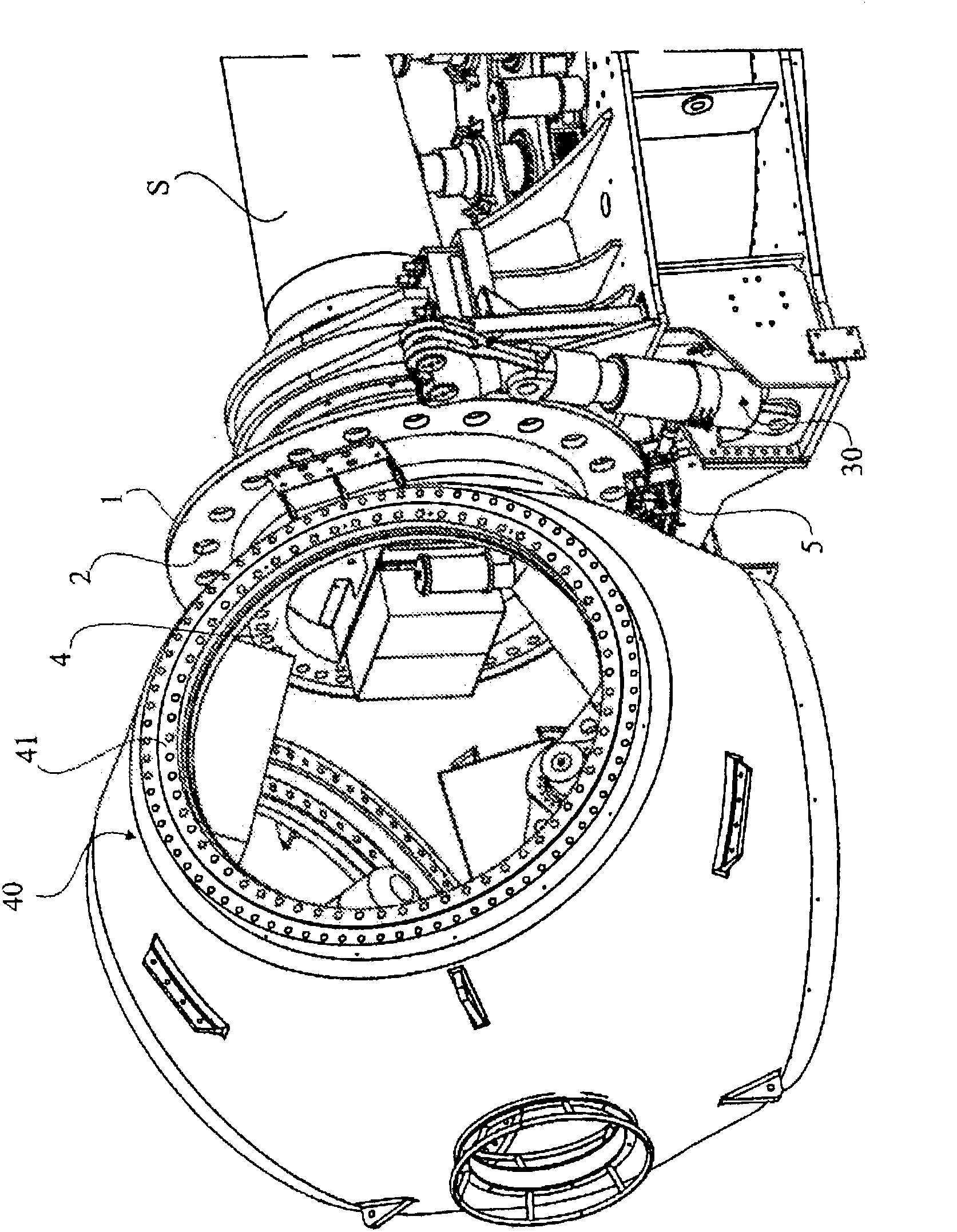

[0023] figure 2 It is a side view of the inside of the machine housing of the wind power plant. The brake disc 1 is mounted centrally to the main shaft S of the wind turbine and has a relatively large diameter generally in the range of 1.5 to 3 metres. The brake disc 1 extends such that part of its circumference enters the gaps of a number of brake units 5 . The brake disc 1 is provided with connection means 2 consisting of a number of through holes distributed evenly over the brake disc 1 at a certain distance from the axis of the brake disc 1 . The number of vias and the angle between vias can vary depending on different requirements. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com