Processing unit for recovering sulphur from insoluble sulphur solvent

A processing device and technology for sulfur, applied in the fields of sulfur compounds, inorganic chemistry, non-metallic elements, etc., to achieve the effects of easy cleaning and post-processing, simple equipment structure and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

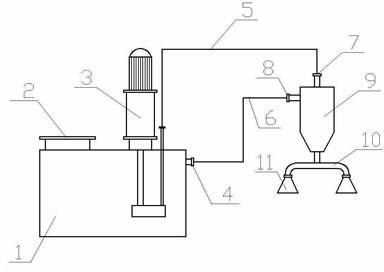

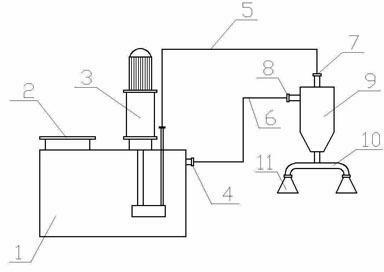

[0009] Attached below figure 1 Examples of the present invention are described.

[0010] The device is provided with a liquid sulfur low level tank 1, and a liquid sulfur inlet 2 is arranged above the liquid sulfur low level tank 1. The liquid suction part of the thermal insulation liquid pump 3 extends in the liquid sulfur low level tank 1, and the pump outlet is connected to the high level through a sulfur transport pipe 5. The upper tank liquid inlet 7 on the top of the tank 9; the upper tank 9 side is also provided with the upper tank return port 8; Unicom. Below the elevated tank 9, a plurality of heat-preservation shower heads 11 are connected through heat-preservation sulfur-distributing pipes 10. In this embodiment, there are two, or three, four or more.

[0011] working principle:

[0012] After the liquid sulfur from the distillation system enters the liquid sulfur low-level tank 1 from the liquid sulfur inlet 2, the thermal insulation submerged pump 3 sends the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com