Combined cord clip

A technology for cable clips and connecting cables, applied in bridge parts, bridges, buildings, etc., can solve the problems of uneven bolt preload, poor stress on the cable clip structure, long length of a single long cable clip, etc. Less stress, good anti-corrosion effect, and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

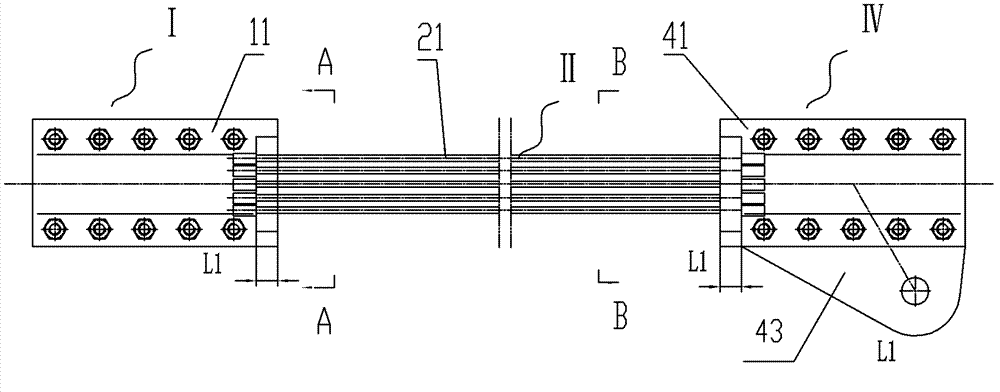

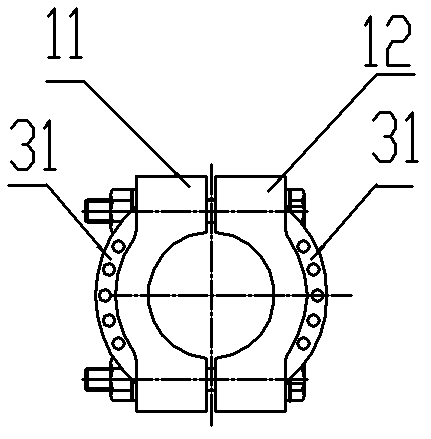

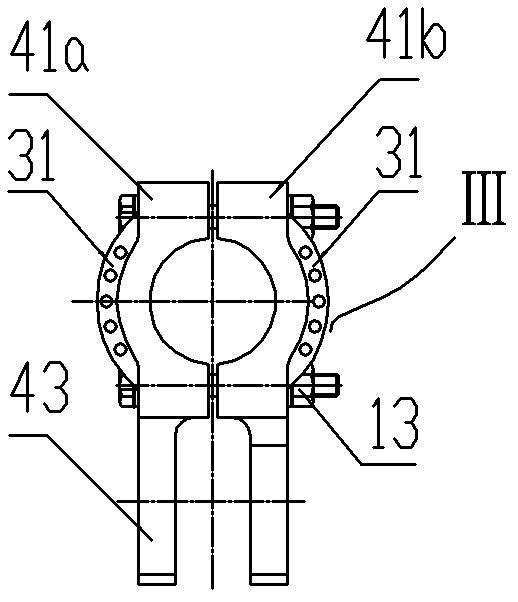

[0068] A steel strand connecting the left and right halves of a separate combined cable clamp, such as Figure 1-1 to Figure 1-4 As shown, the cable clamp IV with lugs is a left and right halves separated cable clamp 41 with lugs, and the cable clamp I without suspension points is two semicircular cable clamp bodies 11 and 12 placed on the left and right. The connecting cable body II of the connecting mechanism is a steel strand 21, and the fixing member III is an anchoring plate 31 connected with a cable clamp without a lifting point or a left and right half-separated cable clamp 41 with lugs. The connection mode between the anchor plate 31 and the cable clamp without suspension point includes making one body with each semicircular cable clamp body of the cable clamp without suspension point respectively or making it separately and then fixedly connected with it; the anchor plate 31 is separated from the left and right halves The connection mode of the ear plate cable clamp 41...

Embodiment 2

[0070] A steel strand connecting the upper and lower halves of a separate combined cable clamp, such as Figure 2-1 to Figure 2-3As shown, the non-suspension point cable clamp I is two semicircular cable clamp bodies 11 and 12 placed up and down, the connecting cable body II of the connecting mechanism is a steel strand 21, and the ear plate The cable clamp is the upper and lower two half-separated type with lug plate cable clamp 42, and the fixed part III is the anchor plate 31 connected with the no-sling point cable clamp or the upper and lower two half-separated type with ear plate cable clamp 41 respectively, The connection mode between the anchor plate 31 and the cable clamp without suspension point includes making one body with the semicircular cable clamp bodies of the cable clamp without suspension point respectively or making it separately and then fixedly connected with it; the anchor plate 31 is separated from the upper and lower The connection mode of the ear plate...

Embodiment 3

[0073] A finished cable with fork lugs at both ends or a steel tie rod connecting the left and right halves of a separate combined cable clamp; Figure 3-1 to Figure 3-3 As shown, the non-suspension point cable clamps are two semicircular cable clamp bodies 11, 12 placed left and right, the connecting cable body II of the connecting mechanism is a finished cable 22 or a steel tie rod 23, and the ear plate The cable clamp is a left and right half-separated type with lug plate cable clamp 41, and the fixed part III is arranged on the left and right sides of the no-sling point cable clamp or the left and right two-half separated type with lug plate cable clamp 41, and is connected with the non-suspended Point cable clip I or the pull plate 32 with the left and right halves of the separated cable clip 41 with lugs connected into one, the connection mode of the pull plate 32 and the cable clip without lifting point includes respectively connecting with each semicircle of the cable c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com