Method for guaranteeing safety of drying system in sulfur phosphate fertilizer production

A drying system and safe technology, which can be used in drying solid materials, drying gas layout, drying, etc., and can solve problems such as explosion, spontaneous combustion, and danger.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

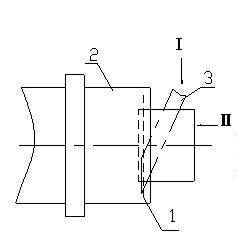

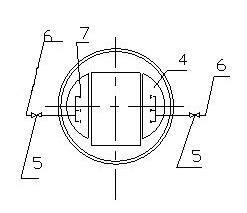

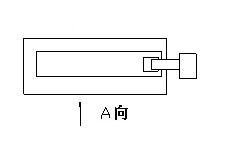

Image

Examples

Embodiment

[0073] Both series of diammonium phosphate plants of Wengfu (Group) Co., Ltd. adopt this process for the production of sulfur-containing phosphate fertilizers. The implementation steps are as follows:

[0074] 1. When the diammonium phosphate plant is producing sulfur-containing phosphate fertilizers (single S and combined S each account for 5%), before the system starts spraying normally, first ensure that the inlet temperature of the dryer is lower than 250°C, and the inlet temperature is controlled by the load of the hot blast stove ;

[0075] 2. Then open the steam spraying system at the inlet of the dryer, let in steam, eliminate the sparks brought by the hot air system in the flue, extinguish the fire source, and then start the system spraying operation. As long as the simple substance S and the material are fully mixed, the surface of the material will The temperature is at most 95°C;

[0076] 3. The moisture inlet of the material is controlled within 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com