Method for mounting large-area refractory fiber module

A fiber module and refractory fiber technology, applied in the direction of the overall lining, etc., can solve the problems of easy sagging, uneven laying, and difficult observation of the tiled carpet, and achieve the effect of easy and fast installation, easy promotion, and good appearance quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] In order to better understand the present invention, the technical solutions of the present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

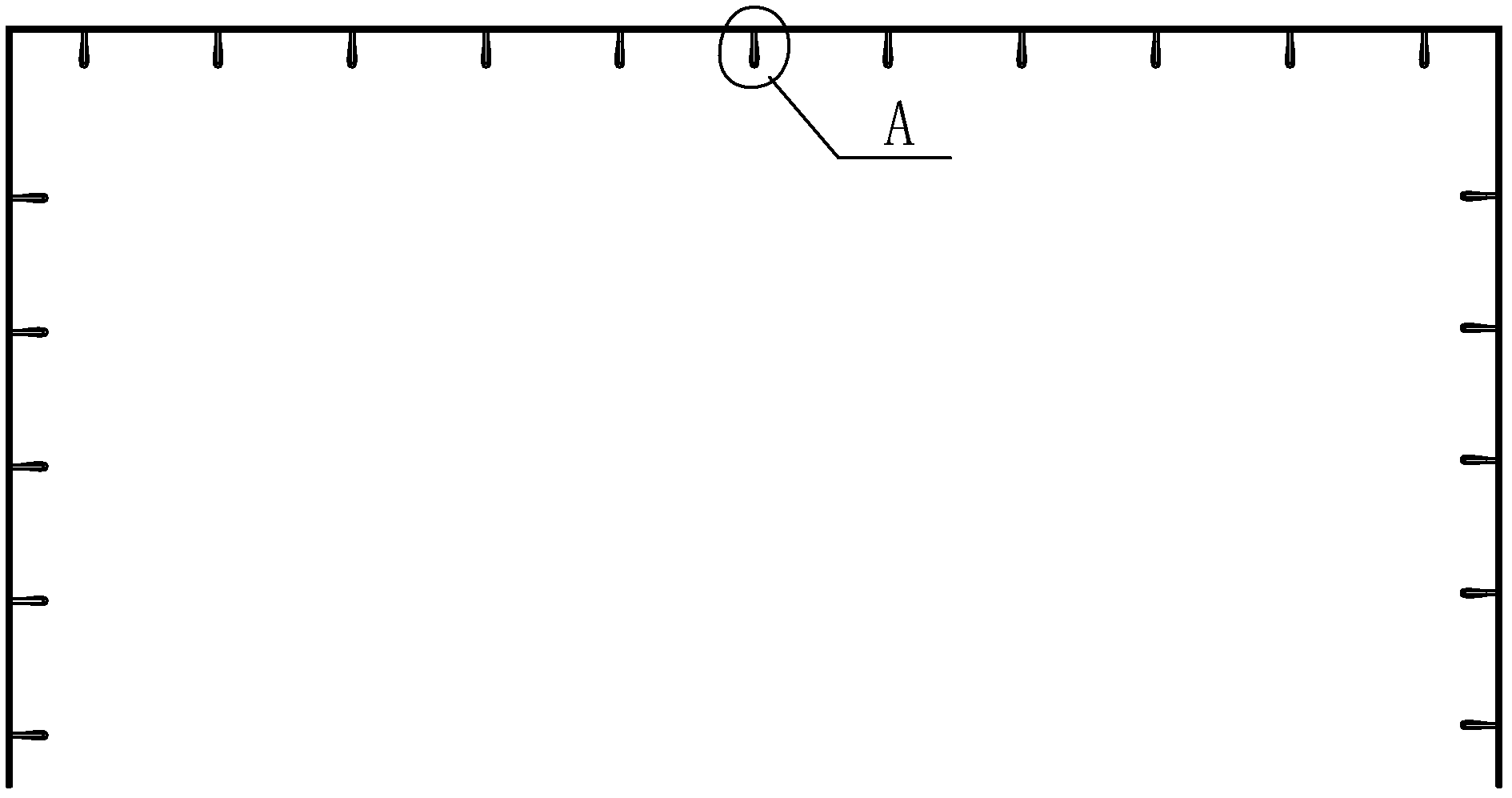

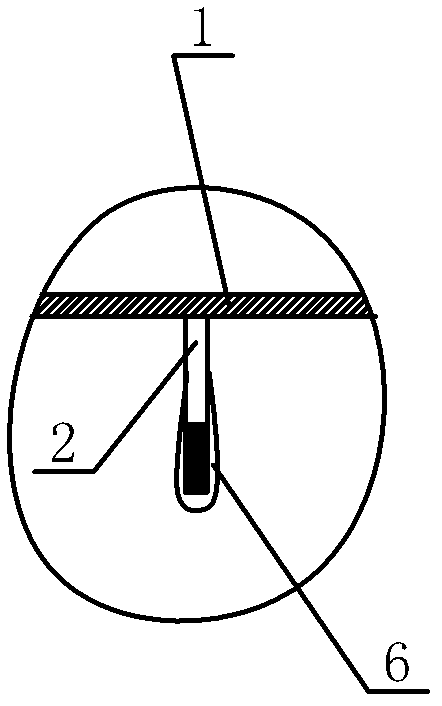

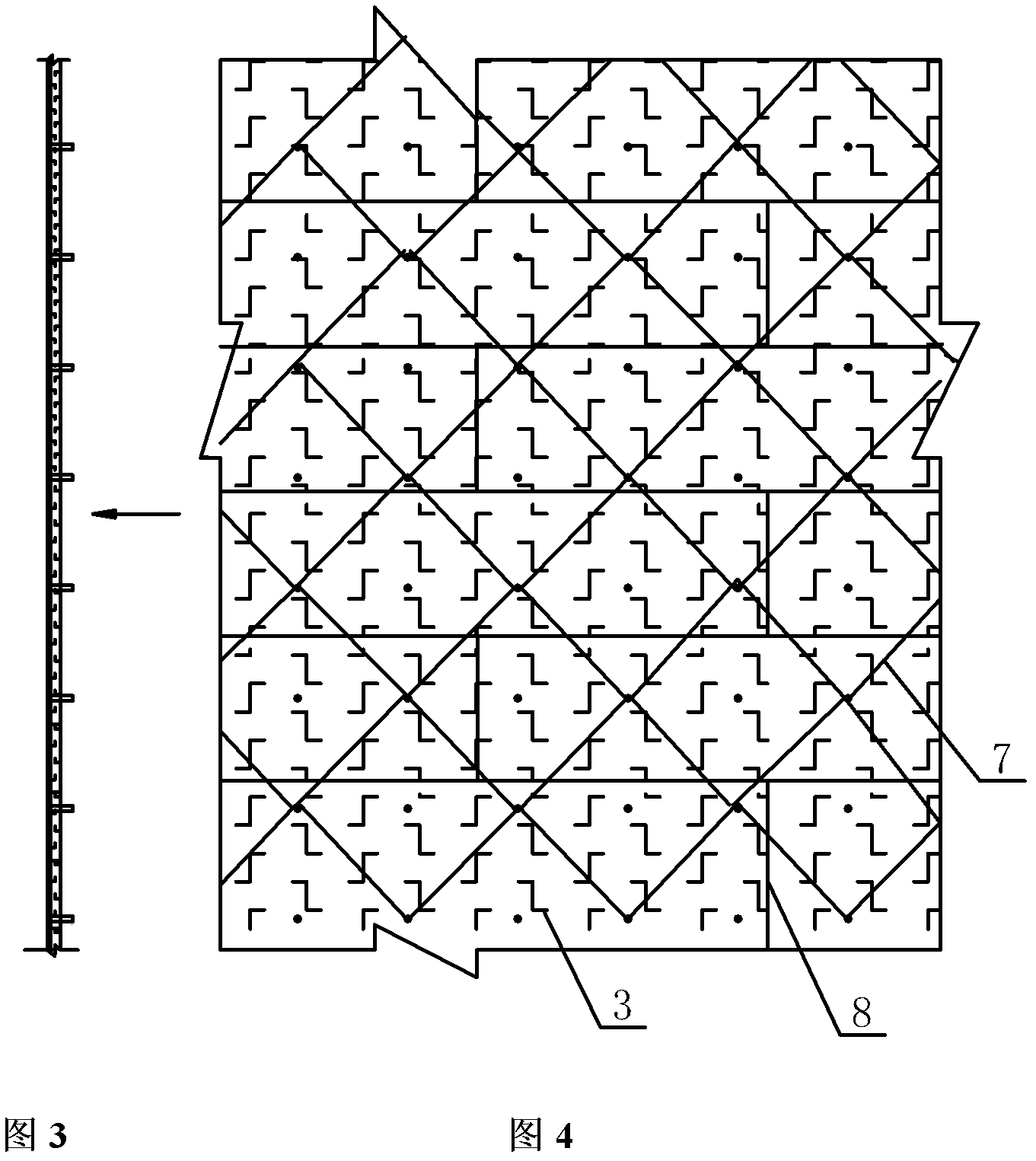

[0063] The large-area refractory fiber module installation method provided by the present invention is to adopt a fiber module installation device mainly composed of a metal guide cylinder 10, a fiber module installation wrench 11, a module installation guide plate 13, a pressure plate 14, and a U-shaped pin 15. For the method of installing fiber modules, see Figure 1 to Figure 15 , the method is:

[0064] The first step of construction preparation: the preparation of necessary auxiliary tools should include metal guide cylinder 10, fiber module installation wrench 11, module installation guide plate 13, pressure plate 14, U-shaped pin 15, and the steel plate of the shell 1 has rust, paint and Oil stains should be dealt with.

[0065] The second step is to measure the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com