Automobile impact test protector

A technology of protective device and crash test, which is applied in the direction of measuring device, vehicle testing, machine/structural component testing, etc., can solve the problems that the protective device structure cannot be moved, difficult to adjust, etc., so as to meet the needs of automobile crash test and increase sliding The effect of friction, ease of movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

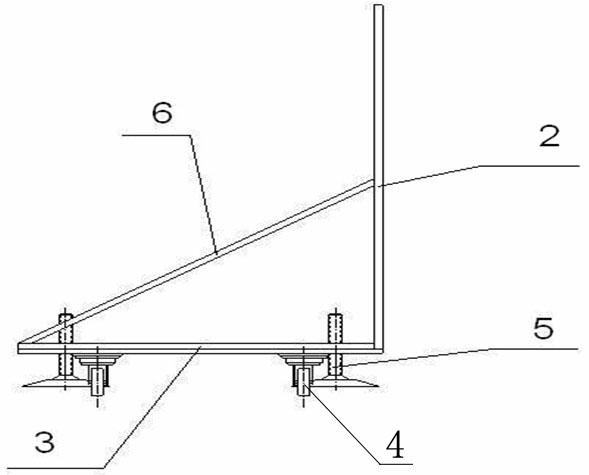

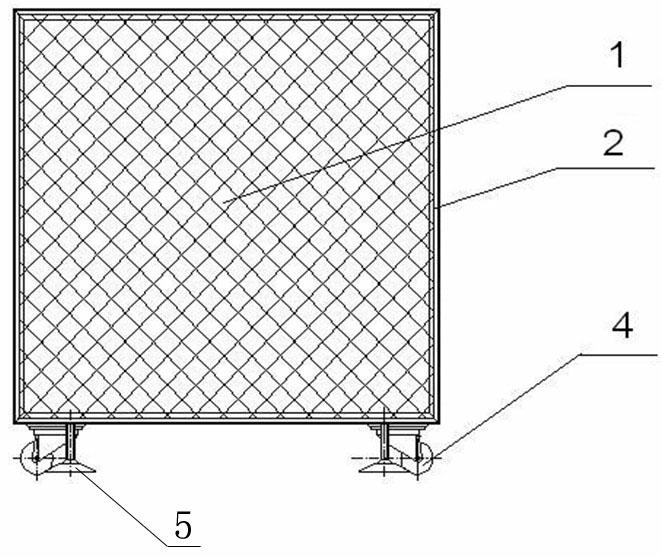

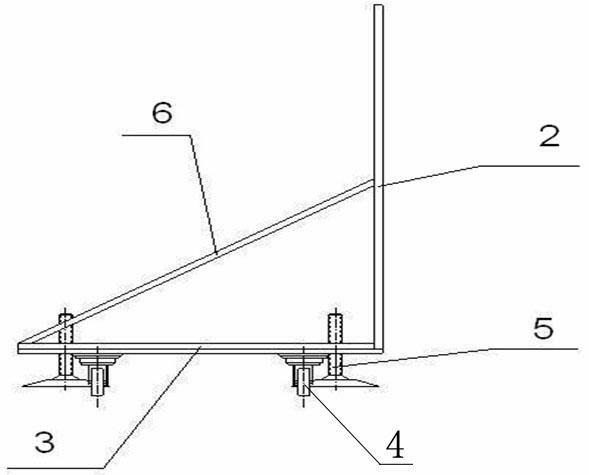

[0013] see figure 1 and figure 2 A car crash test protection device according to the present invention comprises a rectangular base 3, a protective baffle welded vertically on one side of the base, two ends are respectively welded on both sides of the middle and lower part of the protective baffle, and the other ends are welded respectively Rigid support rod 6 on the other side of the base 3; four support feet 5 and four universal wheels 4 are all connected under the base 3, and the upper parts of the four support feet are provided with external threads to cooperate with four threaded holes on the base , can be adjusted up and down; the supporting feet can be adjusted to the lowest point higher than the lowest point of the universal wheel to facilitate the movement of the protective device, and the supporting legs can also be adjusted to the lowest point lower than t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com