Rice improver, cooked rice using same, and processes for preparing cooked rice

一种改良剂、米饭的技术,应用在米饭改良剂领域,能够解决米饭异味、油腻、米饭粘性弱等问题,达到提高松散性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

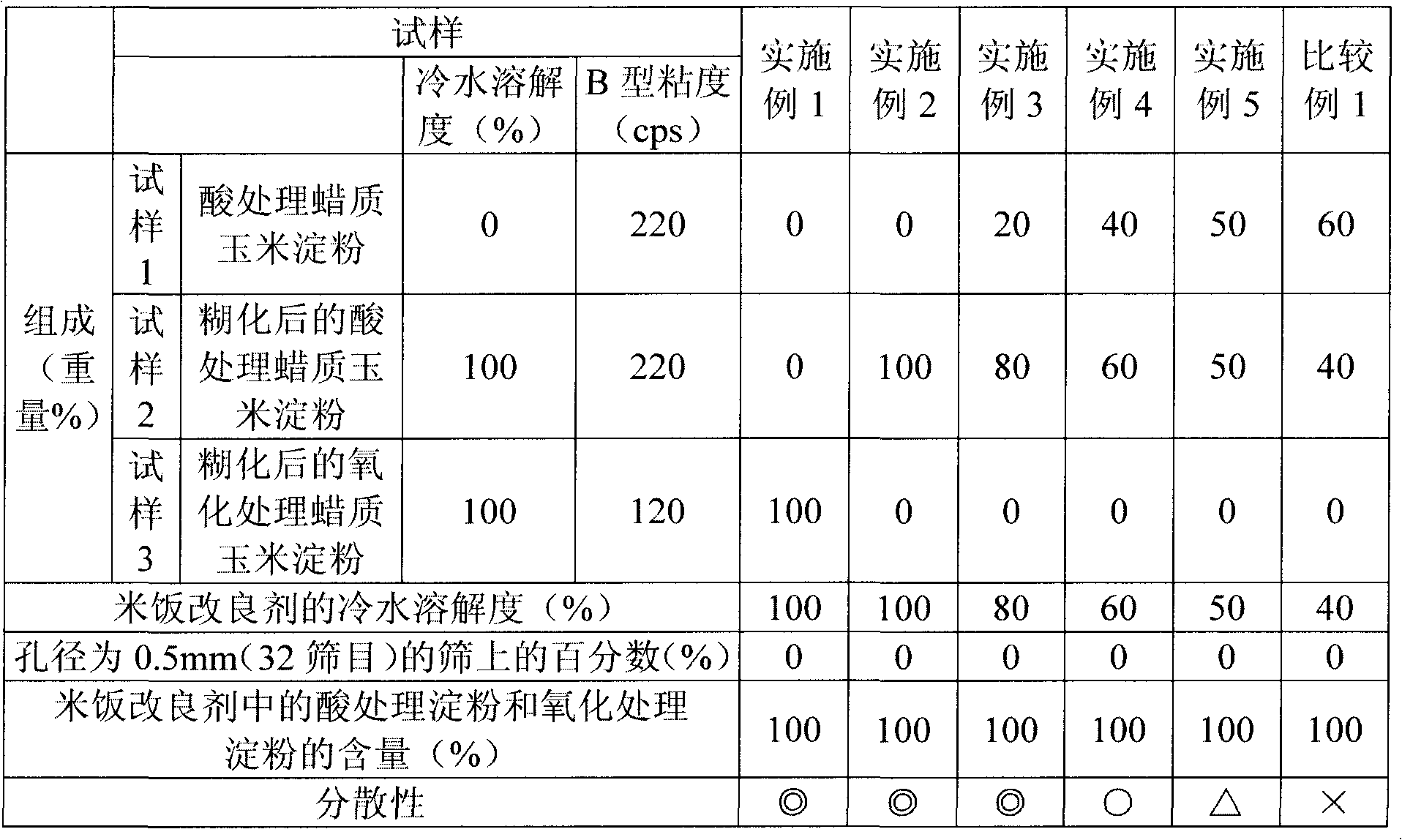

[0049] The rice improving agent in this embodiment contains gelatinized processed product of acid-treated waxy starch or gelatinized processed product of oxidized waxy starch, wherein the total content of the acid-treated waxy starch or oxidized waxy starch is It is 50 weight% or more of the rice improver total amount. In addition, the cold water solubility of the rice improver in pure water at 25° C. is more than 50%, and the content of particles retained on a sieve with an aperture of 0.5 mm (32 meshes) in the rice improver is less than 5% by weight.

[0050] The gelatinization treatment mentioned here refers to the treatment of substantially completely destroying the granular structure of starch by heating or alkali treatment. The starch that has been gelatinized is different from the ungelatinized starch that is insoluble in cold water, and has a basic solubility in cold water. specialty.

[0051] As a specific method of gelatinization treatment, starch suspension is prep...

no. 2 approach

[0067] In this embodiment, the raw material containing acid-treated or oxidized waxy starch is processed into granular form and used. For example, the rice improver in this embodiment is mainly composed of acid-treated or oxidized waxy starch processed into granules.

[0068] The granular shape in the present embodiment refers specifically to the particles that remain 5% by weight or more and 100% by weight or less on a sieve with an aperture of 0.5 mm (32 meshes) according to JIS standards, and the shape is not limited. From the standpoint of dispersibility and stability of the rice improving effect, it is preferable that the content of the particulate matter remaining on the sieve with an aperture of 0.5 mm (32 mesh) is 80% by weight or more.

[0069]The rice improver in the present embodiment is made by using raw materials containing acid-treated or oxidized waxy starch to retain 5% by weight to 100% by weight of granular matter on a sieve with a pore size of 0.5 mm (32 mes...

Embodiment

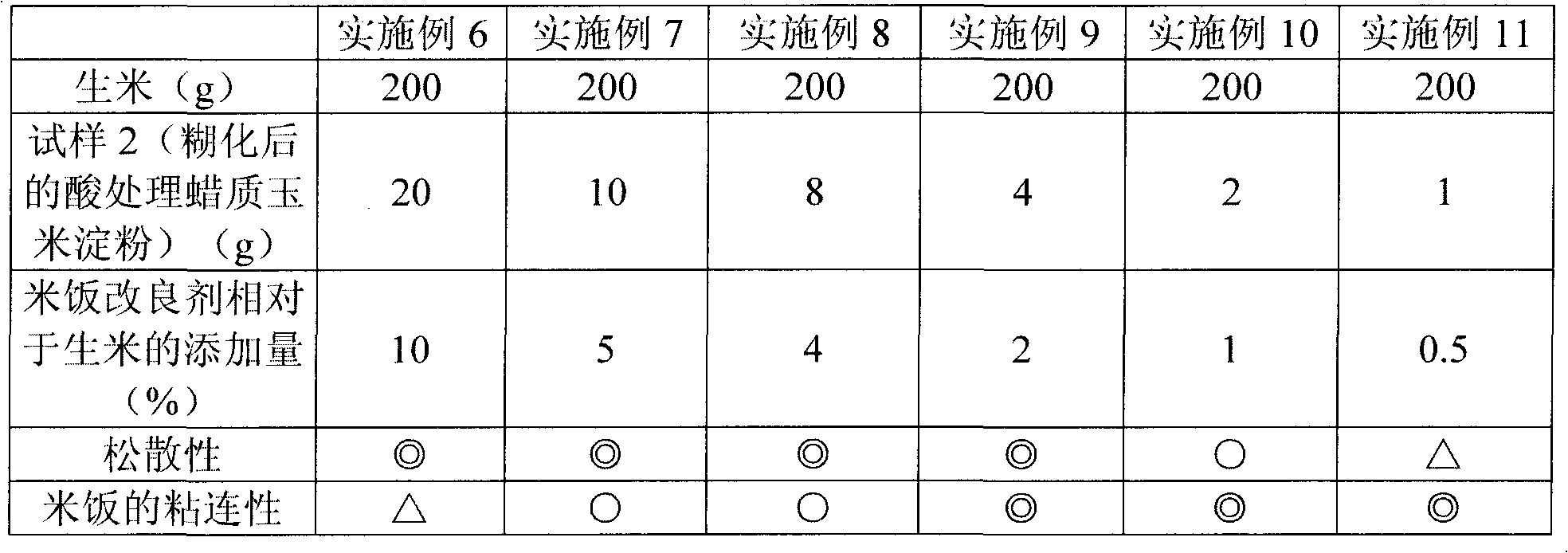

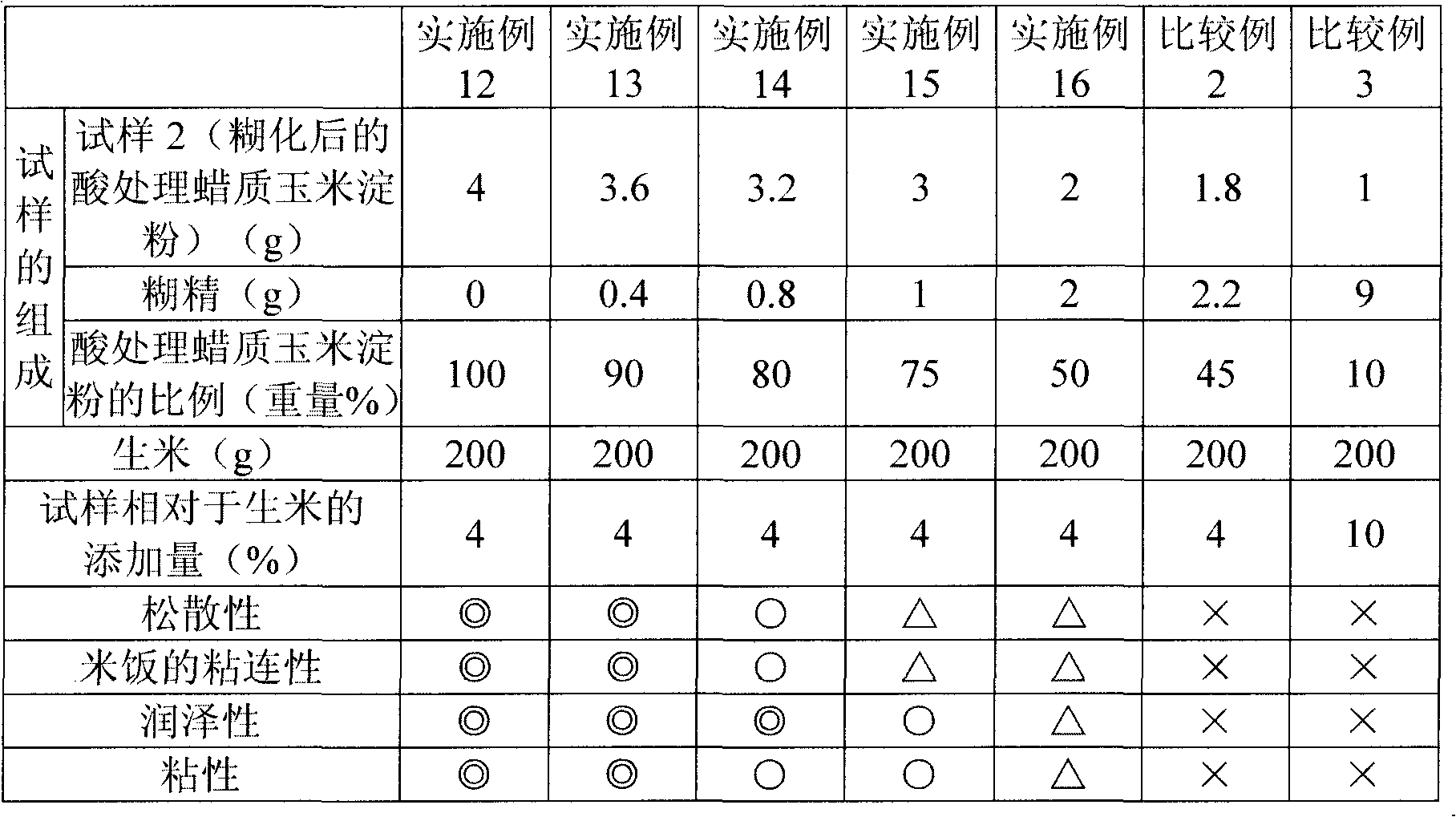

[0091] Examples of the present invention will be described below, but the gist of the present invention is not limited to these.

[0092] In addition, in the following examples, the B-type viscosity was measured at 30 rpm using a viscometer BM manufactured by Tokyo Keiki Co., Ltd.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com