A high-strength KT board

A high-strength, board-core technology, applied in the field of KT boards, can solve the problems of inability to bear loads and low strength of KT boards, and achieve high strength, improved application range, and good antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

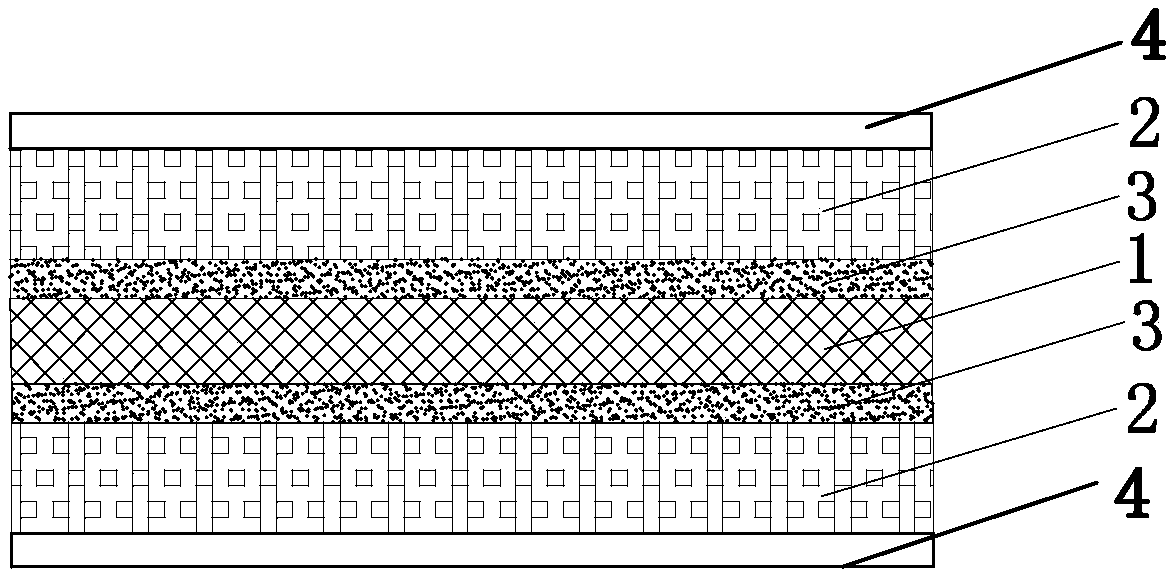

[0027] A high-strength KT board, including a core layer 1 and a paper layer 2, the core layer is sandwiched between two paper layers, and the core layer and the paper layer are passed through Adhesive 3 is bonded, the material of the core layer is polystyrene, the overlay paper layer is white cardboard, and a plastic film 4 is pasted on the outside of the overlay paper layer, and the material of the plastic film is polypropylene.

[0028] Adhesive comprises the following components by weight:

[0029] 60 parts of modified hydroxyacrylic resin, 1 part of dicyandiamide, 1 part of trichloroethyl phosphate, 1 part of butadienyl triethoxysilane, 1 part of melamine cyanuric acid, and 1 part of zinc oxide.

[0030] The preparation method of modified acrylic resin is as follows:

[0031] 1) Add 20mL of acrylic acid and 3g of polyvinyl alcohol into 150mL of deionized water, stir to dissolve, then add 0.02mol of azobisisobutyronitrile, heat up to 50°C, and stir for 2 hours to obtain re...

Embodiment 2

[0036] A high-strength KT board, including a core layer 1 and a paper layer 2, the core layer is sandwiched between two paper layers, and the core layer and the paper layer are passed through Adhesive 3 is bonded, the material of the core layer is polystyrene, the overlay paper layer is coated paper, and a plastic film 4 is pasted on the outside of the overlay paper layer, and the material of the plastic film is polyvinyl chloride.

[0037] Adhesive comprises the following components by weight:

[0038] 65 parts of modified hydroxyacrylic resin, 1 part of dicyandiamide, 1 part of trichloroethyl phosphate, 1 part of butadienyl triethoxysilane, 1 part of melamine cyanuric acid, and 1 part of zinc oxide.

[0039] The preparation method of modified acrylic resin is as follows:

[0040] 1) Add 24mL of acrylic acid and 4g of polyvinyl alcohol into 160mL of deionized water, stir to dissolve, then add 0.03mol of azobisisobutyronitrile, raise the temperature to 52°C, and stir for 2.3h...

Embodiment 3

[0045] A high-strength KT board, including a core layer 1 and a paper layer 2, the core layer is sandwiched between two paper layers, and the core layer and the paper layer are passed through Adhesive 3 is attached, the material of the core layer is polystyrene, the overlay paper layer is white board paper, and a plastic film 4 is pasted on the outside of the overlay paper layer, and the material of the plastic film is polystyrene.

[0046] Adhesive comprises the following components by weight:

[0047] 70 parts of modified hydroxyacrylic resin, 1.5 parts of dicyandiamide, 2 parts of trichloroethyl phosphate, 1.5 parts of butadienyl triethoxysilane, 1.5 parts of melamine cyanuric acid, and 2 parts of zinc oxide.

[0048] The preparation method of modified acrylic resin is as follows:

[0049] 1) Add 26mL of acrylic acid and 4.5g of polyvinyl alcohol into 170mL of deionized water, stir to dissolve, then add 0.035mol of azobisisobutyronitrile, heat up to 55°C, and stir for 2.5h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com