Hand-operated hydraulic press with drilling jig

A technology of drilling jig and hydraulic press, which is applied in the direction of clamping, manufacturing tools, metal processing equipment, etc., can solve the problems of frequent wear and uncontrollable balanced tightening, etc., achieve the effects of firm fixation, solution of positional deviation, and improvement of work efficiency

Inactive Publication Date: 2013-11-20

刘恩宏

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, it is impossible to control the balanced tightening by the feeling of the hand. Moreover, these screws have to be tightened and loosened every time a workpiece is processed, causing frequent wear and tear.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

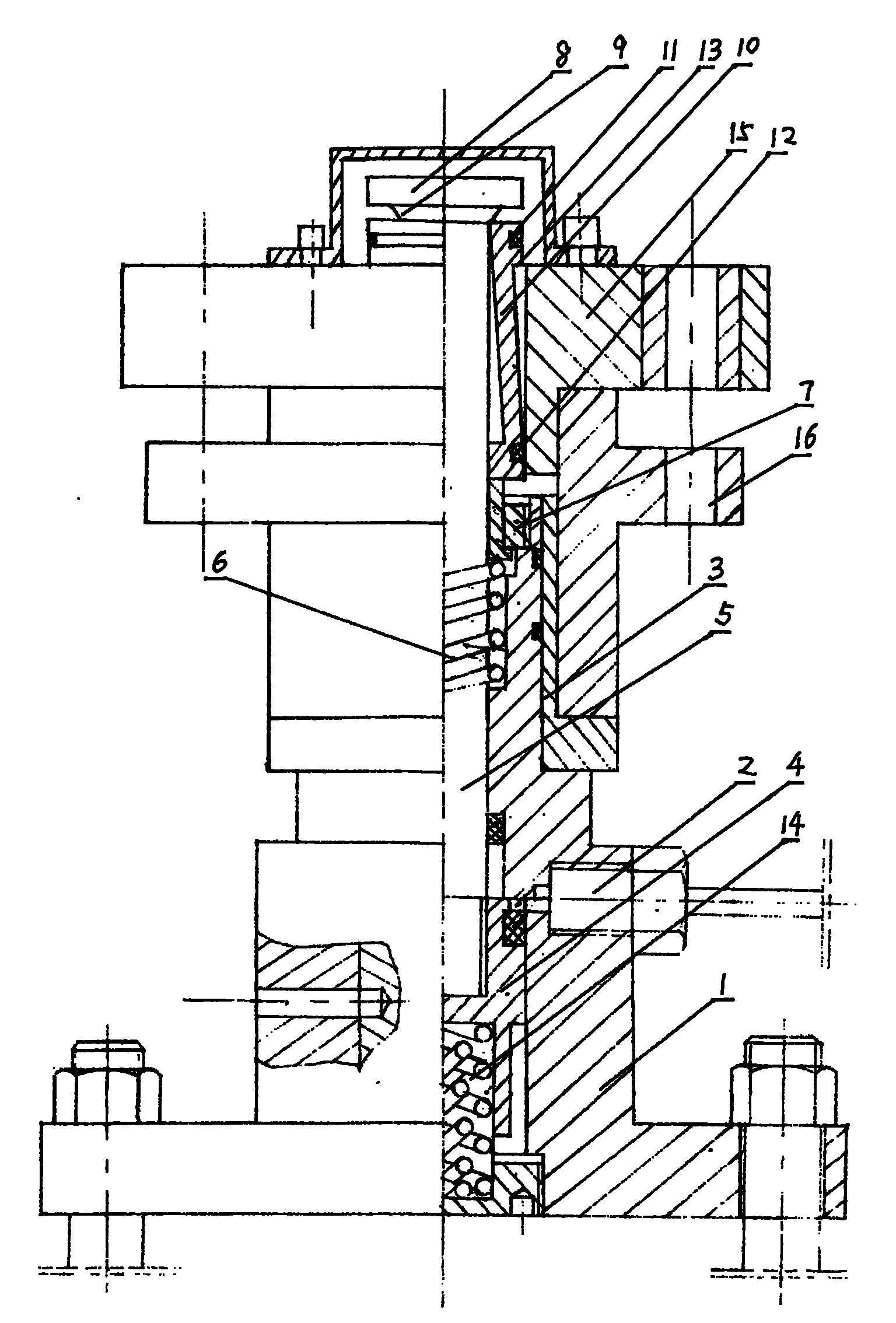

The invention relates to a hand-operated hydraulic press with a drilling jig, belonging to the technical field of machine manufacturing. The hand-operated hydraulic press with a drilling jig is composed of a base, a hydraulic device, a shaft cavity, a draw rod, a return spring, a differential spring, a spacing seat, a gland, a buckling block, an upper tightening loop, a lower tightening loop and a drilling jig, wherein the shaft cavity is fixed on the base; the lower part of the draw rod is arranged in the shaft cavity; the bottom of the draw rod is connected with a piston of the hydraulic device; the top end of the draw rod is fixedly connected with the gland through a conical neck; the draw rod is provided with the buckling block; the top of the shaft cavity is provided with the spacing seat; and the upper surface of the drilling jig is corresponding to the position of the clamping platform of the buckling block. The hand-operated hydraulic press with a drilling jig is operated in the following way: a workpiece is sheathed in the shaft cavity, the drilling jig is pressed on the workpiece, the draw rod moves downward, and the clamping platform of the buckling block drives the drilling jig to compress the workpiece, thereby clamping the workpiece. The invention can accurately position the processed workpiece, and solves the problem of true position deviation.

Description

technical field [0001] The invention belongs to the technical field of mechanical manufacturing, and relates to a clamp. Background technique [0002] At present, the commonly used machine-added drilling jigs are fixed with screw pressure bridge plates, fixed with screw gland plates, and also fixed with tapered iron pin grooves, and fixed with drill mold glands with double lug reverse buckle tension and pressure belt positioning holes, etc. These toolings have cumbersome and time-consuming operating procedures. It is difficult to achieve quantitative production of programmed and large-scale drilling workpieces. The positioning deviation is too large. At the same time, the tooling parts are easy to wear, and the workpiece is unbalanced and directly Affects the position of drilling and other issues. [0003] For example, for tooling with double-hanging lugs, buckle, pull and press with positioning holes, the table top should be cleaned first for each workpiece to be processed...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B23Q3/06B23B47/28

Inventor 刘恩宏刘国方

Owner 刘恩宏

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com