Tool and process for processing white optical lens concave surface with diopter

A technology for optical lenses and leucovorans, applied in optical surface grinders, metal processing equipment, manufacturing tools, etc., can solve problems such as environmental pollution, damage to human respiratory function, and adverse production costs, so as to reduce production costs and avoid health problems. damage, improve productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

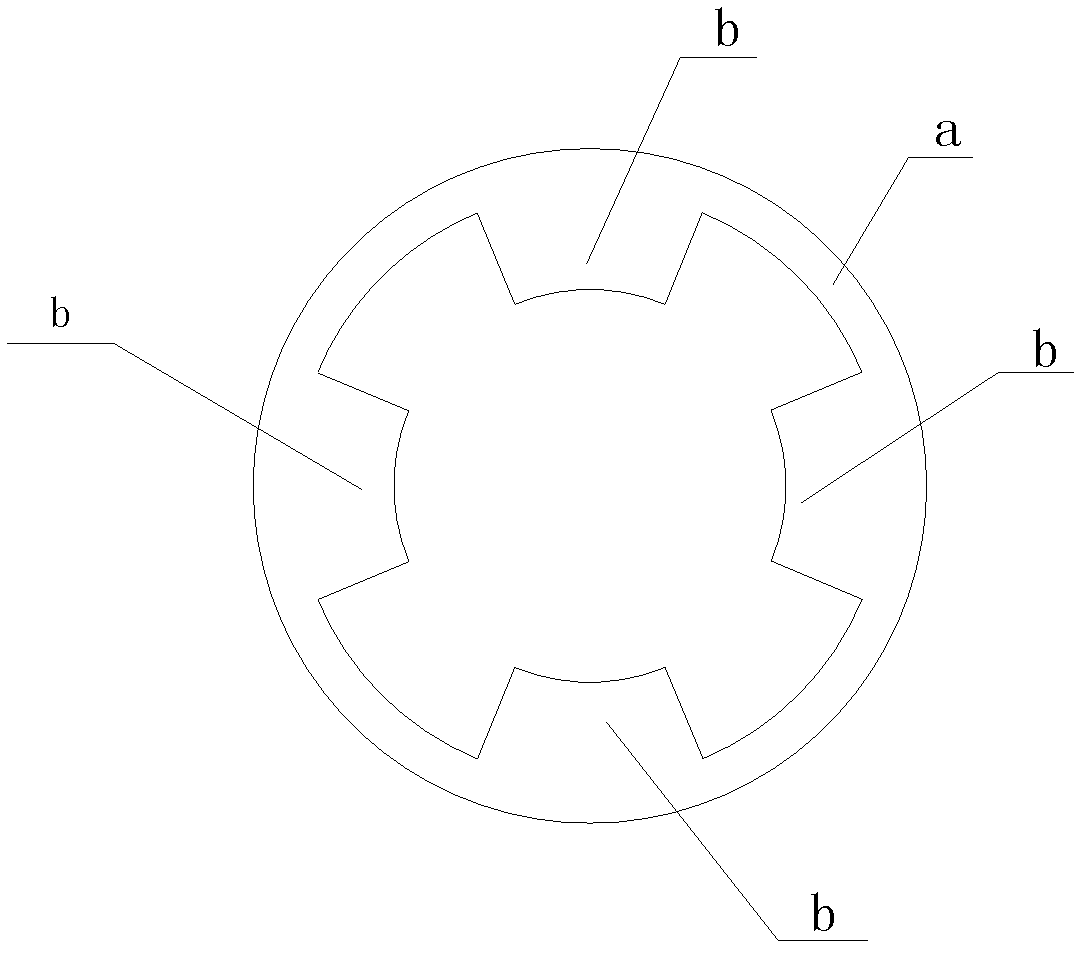

[0043] This embodiment is a kind of optical lens white film diopter concave processing tooling, which has a disc-shaped main body and double-sided adhesive stickers. Such as figure 1 As shown, the double-sided adhesive tape has a narrow ring a attached to the peripheral edge of the bottom surface of the disc-shaped main body, and the narrow ring a is connected with two pairs of fan-shaped tabs that are symmetrically distributed and point to the center of the bottom surface of the disc-shaped main body. b, the fan-shaped protruding piece b is pasted within the narrow ring a on the bottom surface of the disc-shaped main body.

[0044] Use the technical method of the optical lens white sheet diopter concave processing tooling of the present embodiment, carry out according to the following steps:

[0045] (1) Paste the disc-shaped main body on the white side of the optical lens with the help of double-sided adhesive tape;

[0046] (2) Clamping the disc-shaped main body on a grin...

Embodiment 2

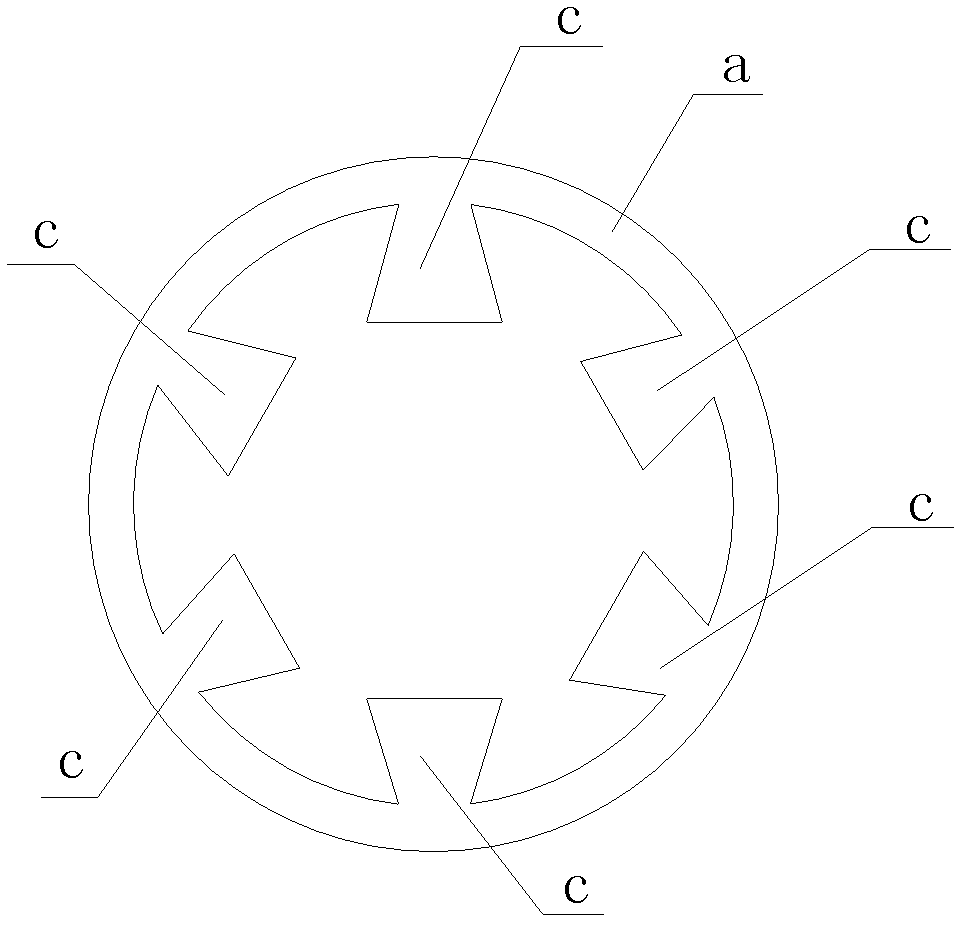

[0049] This embodiment is similar to Embodiment 1, the difference lies in the shape of the protruding piece, the protruding piece of this embodiment is a trapezoidal protruding piece c, and the narrow ring a is connected with three pairs that are symmetrically distributed and point to the center of the bottom surface of the disc-shaped main body. The trapezoidal lug c is pasted within the narrow ring a on the bottom surface of the disc-shaped main body.

[0050] The processing method of using the diopter concave surface processing tool of the optical lens white sheet of this embodiment is the same as that of Embodiment 1.

Embodiment 3

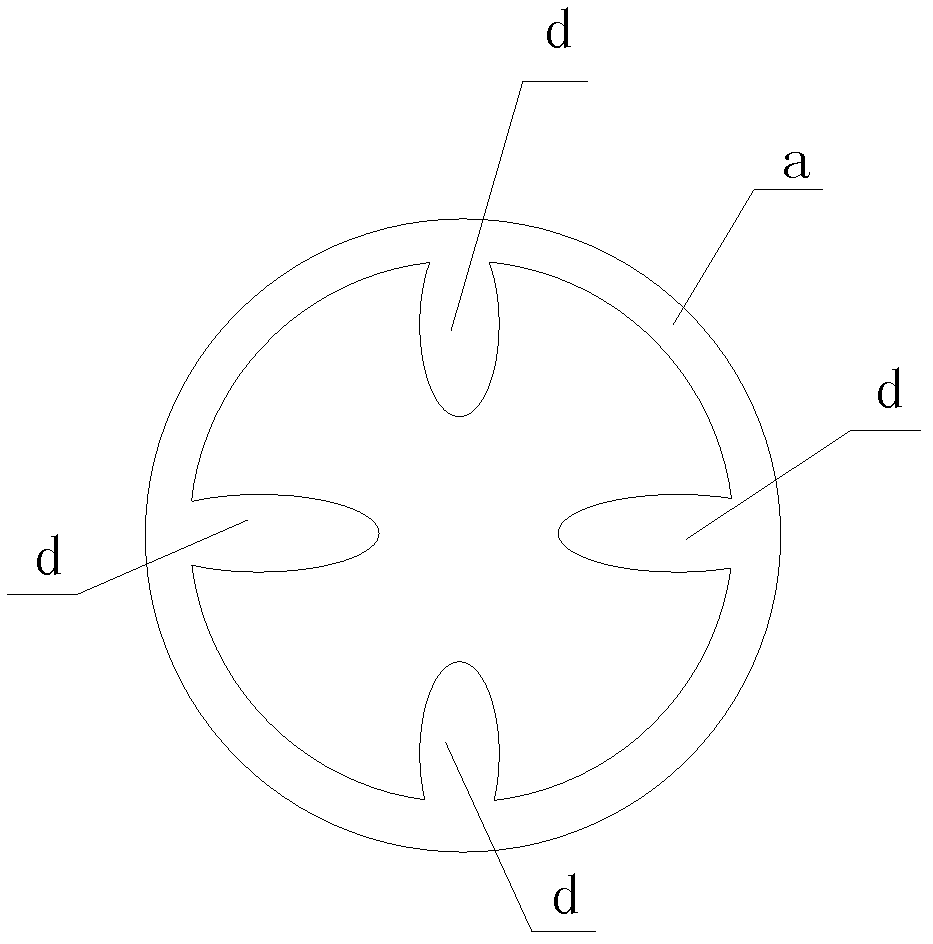

[0052] This embodiment is similar to Embodiment 1, the difference lies in the shape of the protruding piece, the protruding piece of this embodiment is an elliptical protruding piece d, and there are two pairs of symmetrically distributed pointing to the center of the bottom surface of the disc-shaped main body connected to the narrow ring a The elliptical convex piece d, the elliptical convex piece d is pasted within the narrow ring a of the bottom surface of the disc-shaped main body.

[0053] The processing method of using the diopter concave surface processing tool of the optical lens white sheet of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com