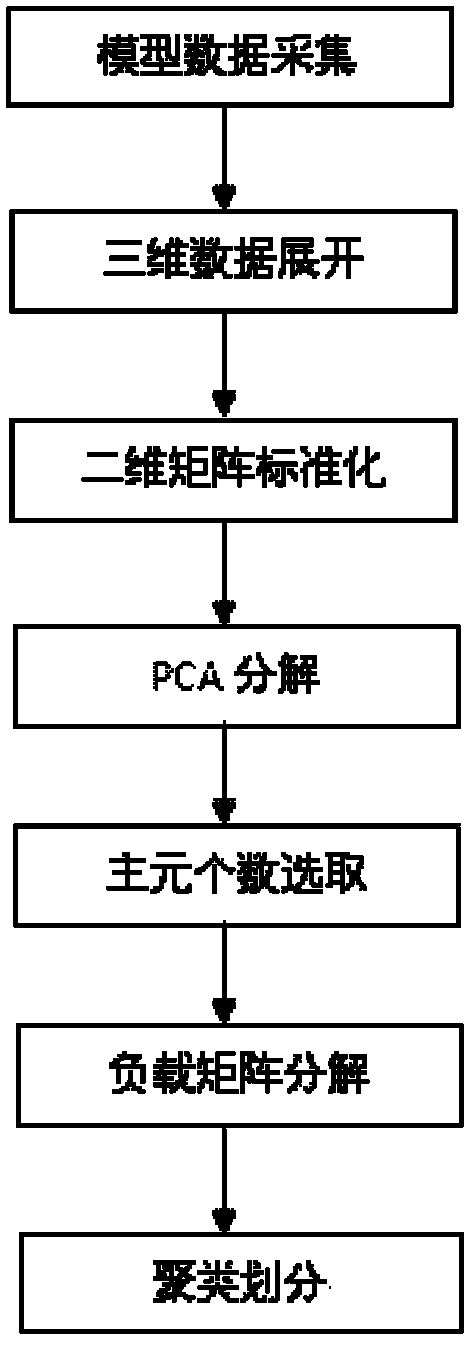

Multi-phase batch process phase dividing method based on multiway principal component analysis method

A principal component analysis method and multi-stage technology, applied in the field of multi-stage batch process stage division, can solve problems such as too subjective judgment results, rough stage identification, and no consideration of process variable correlation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

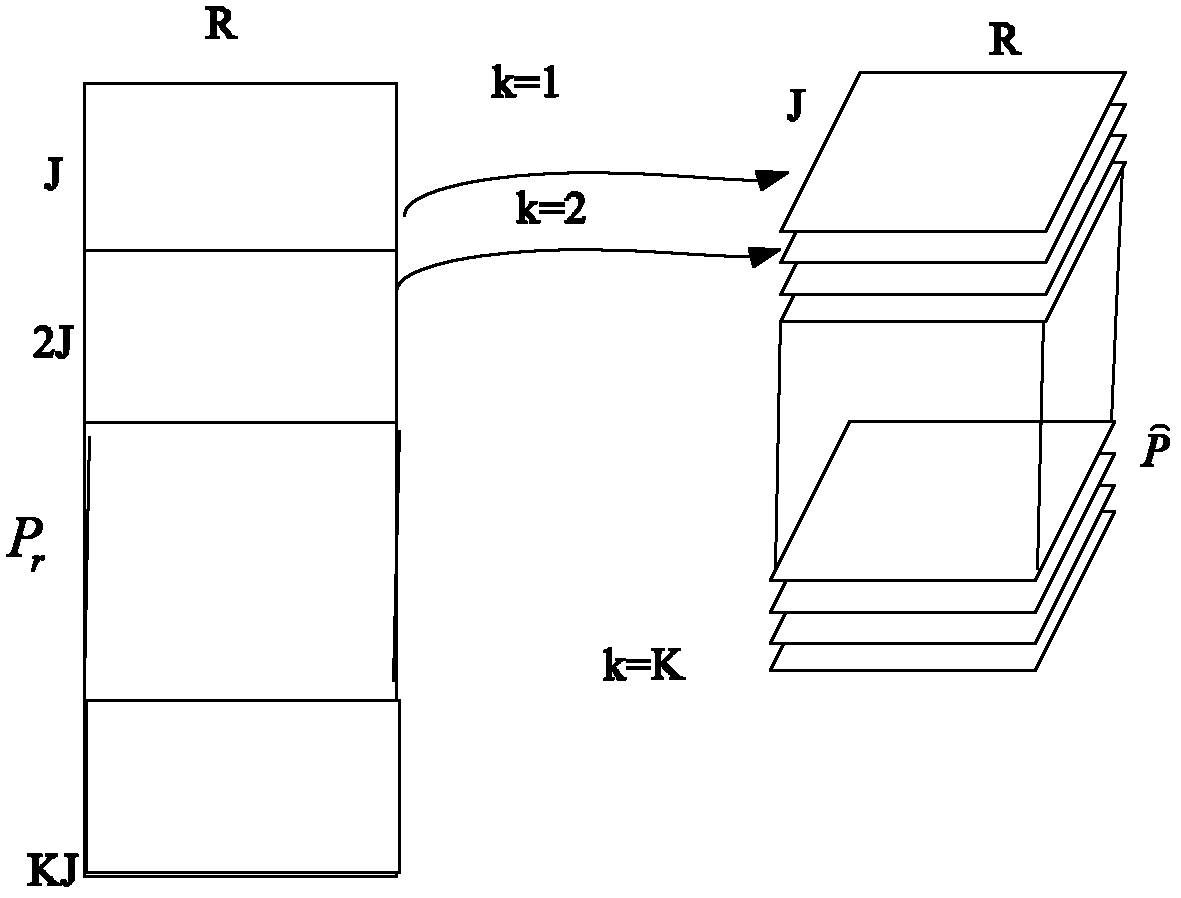

Method used

Image

Examples

Embodiment Construction

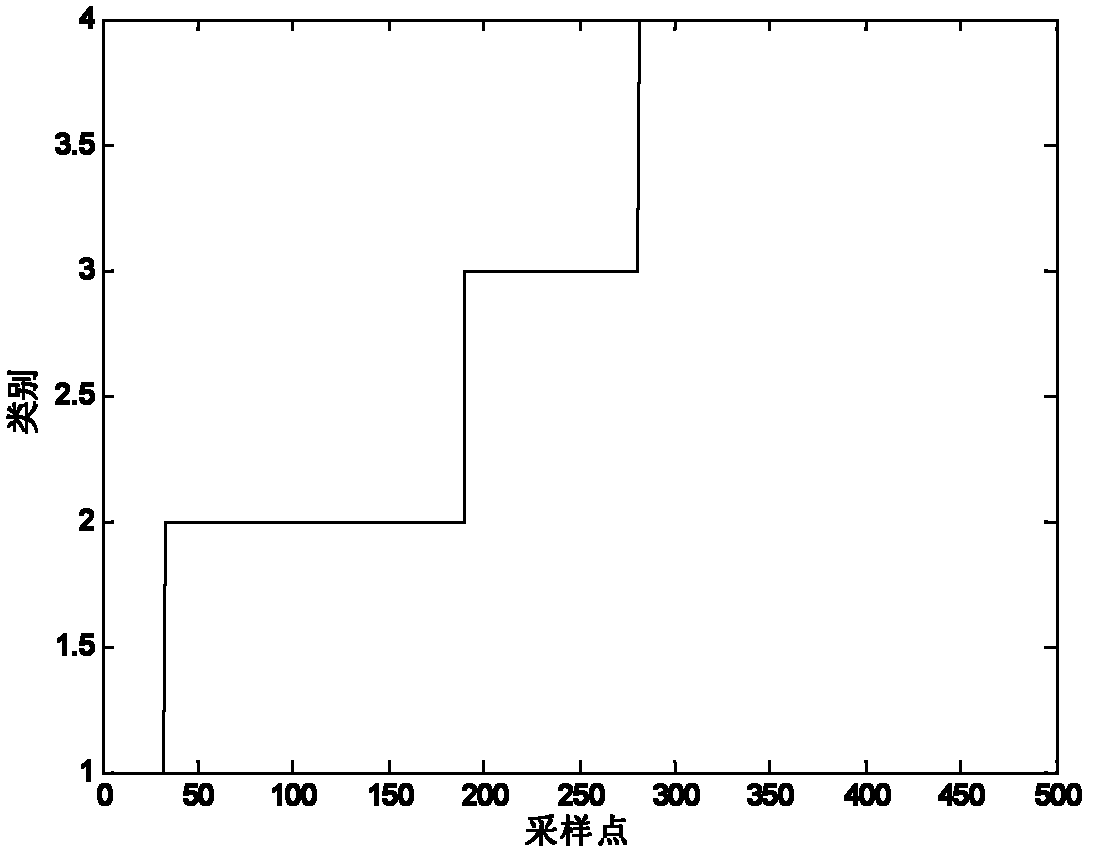

[0052] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be further described:

[0053] Injection molding is a typical multi-stage batch process, which mainly includes four stages: injection, pressure holding, plasticization, and cooling. Each period of the injection molding process has its specific control objectives, different leading variables and process characteristics. Specifically, in the injection section, the high pressure of the hydraulic cylinder pushes the screw forward to push the molten plastic in the barrel to the mold cavity. When the mold cavity is completely or nearly full, the process switches to the pressure holding stage. In this stage , the high pressure continues to fill a small amount of material into the mold cavity to supplement the material shrinkage caused by cooling and solidification; when the glue mouth is cooled and the material in the mold cavity is no longer affected by the injection nozzle, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com