Heavy battened steel column construction process

A construction technology and steel column technology, applied in construction, building structure, construction material processing and other directions, can solve the problems of difficult control of axis deviation and verticality, high engineering cost, large value to be adjusted, etc., and achieve the adjustment process time. Short, save engineering cost, eliminate the effect of positive tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

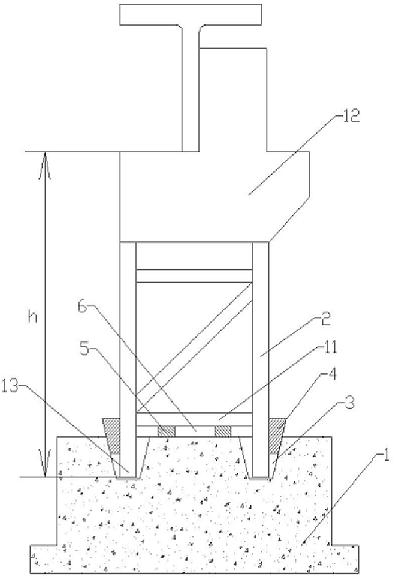

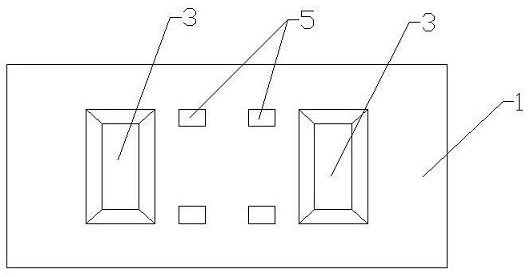

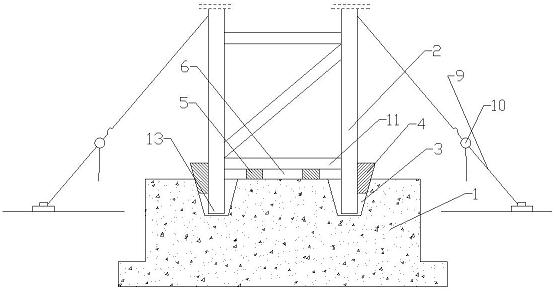

[0037] Embodiment, select an industrial factory building, the structural overview is a single-layer steel structure, such as figure 1 As shown, the foundation cap 1 and the pillars are heavy-duty double-legged steel columns 2, and corbels 12 are installed above the heavy-duty double-limbed steel columns 2, and the height of the columns is 9 meters. The installation of the steel columns by the present invention requires 13 bases of the column feet The offset of the center line to the positioning axis cannot be greater than 5mm, the allowable deviation of the elevation of the column reference point is controlled within +3mm to -5mm, and the verticality of the column axis cannot be greater than H / 1000. In this case, H is 9mm.

[0038] During the construction of the foundation cap 1, in order to ensure the correctness of the elevation of the bottom of the cup-shaped foundation, the size of the cup-mouth formwork must be ensured to be accurate. The elevation of the foundation beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com