Exhaust line for an internal combustion engine

An exhaust pipe, internal combustion engine technology, applied in exhaust devices, mechanical equipment, engine components, etc., can solve problems such as increasing the complexity of exhaust pipes, achieve short response time, reduce weight and cost, and reduce complexity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

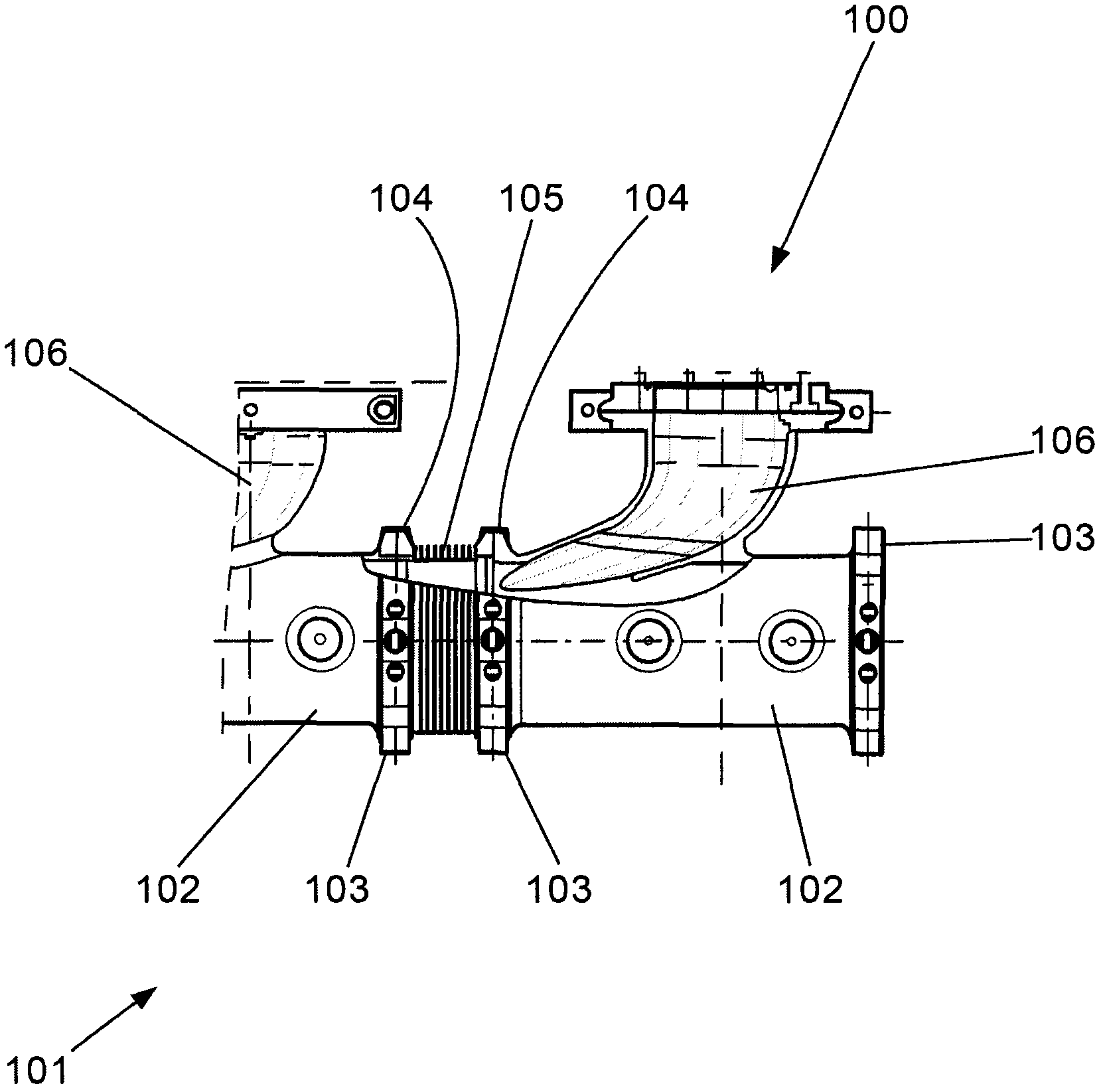

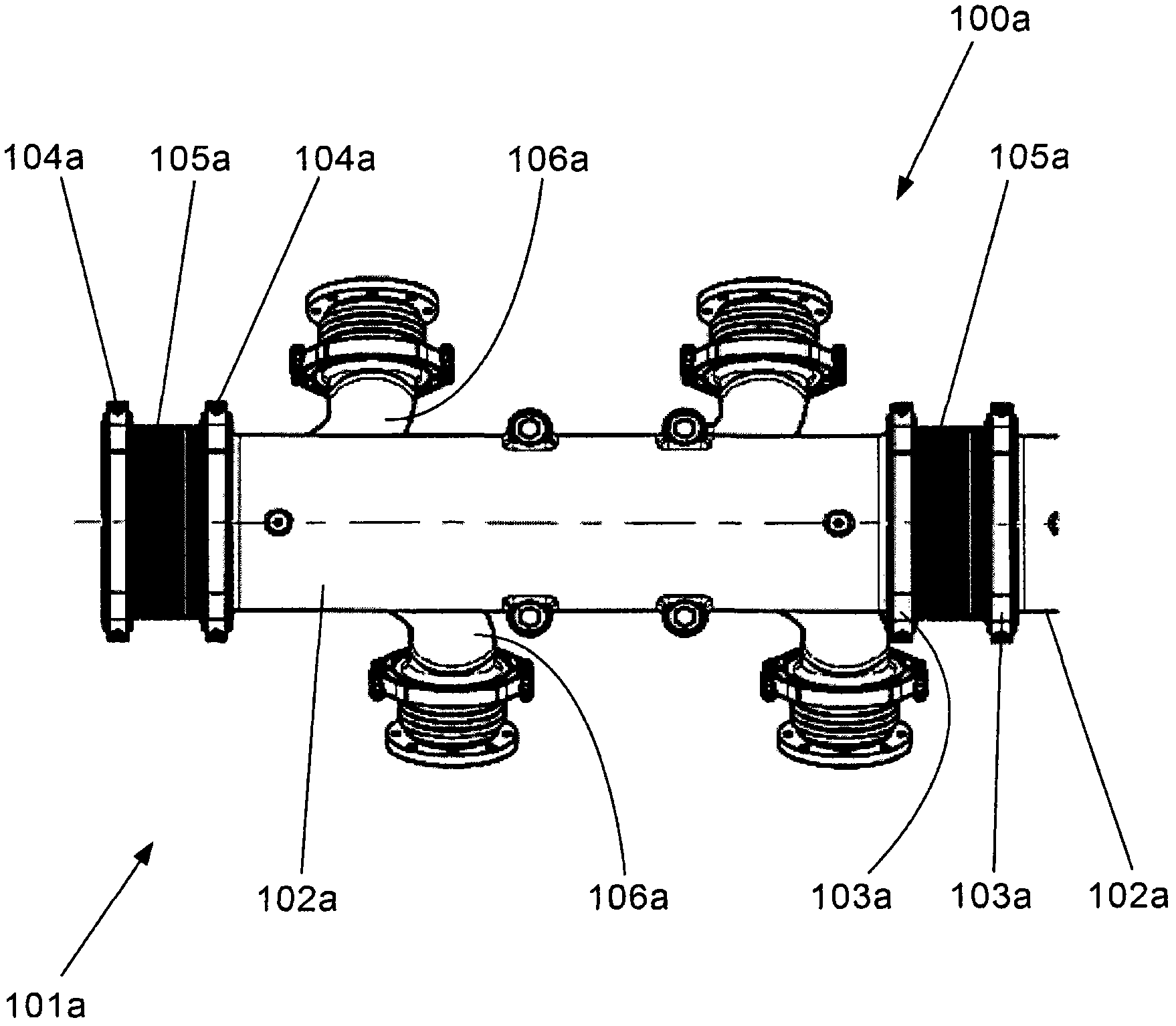

[0066] figure 1 with figure 2 Two examples of exhaust pipes 100, 100a for internal combustion engines (not shown) manufactured to date by the applicant are shown.

[0067] Such as figure 1 As shown, the exhaust pipe 100 has a line arrangement 101 with a plurality of individual pipe segments 102 made of, for example, cast iron. Within the longitudinal extension of the line arrangement 101, a deformation compensation element 105 is arranged between two adjacent pipe sections 102 (in the figure 1 Only one deformation compensator is shown in ) for absorbing the deformation of the line set 101 . In order to connect the individual pipe sections 102 and deformation compensators 105 , clamping clip couplings 103 are respectively provided at the respective longitudinal ends of these components, which are joined together with clamping clips 104 .

[0068] Each pipe segment 102 has, laterally on its wall, a cylinder connection 106 for the exhaust gas of a cylinder (not shown) of an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com