Scroll compressor

A scroll compressor and scroll technology, applied in the field of compressors, can solve the problems of compressor bearing burn, heat transfer performance deterioration, reliability problems, etc., and achieve the effects of reducing oil leakage, slowing flow rate, and improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

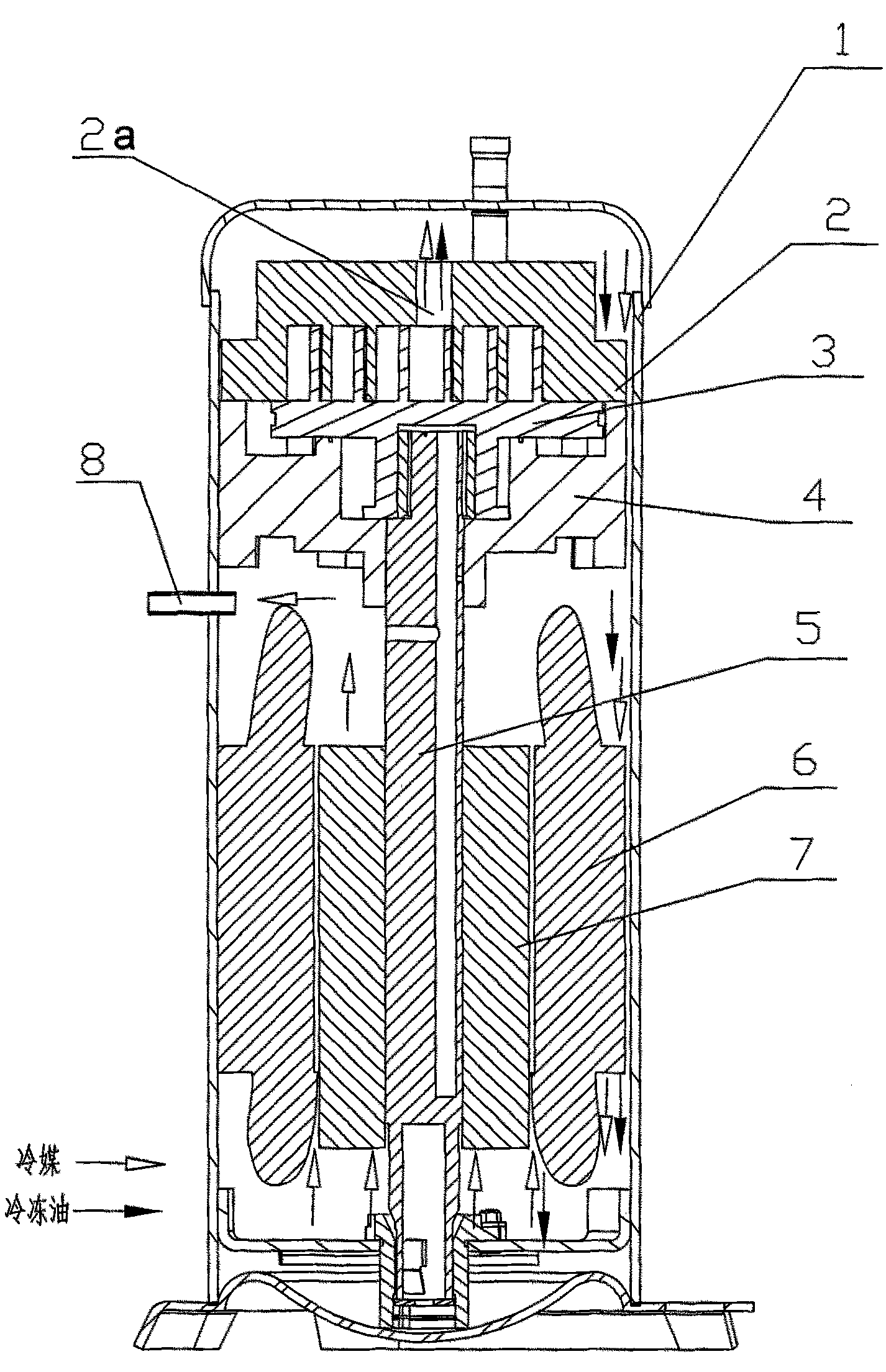

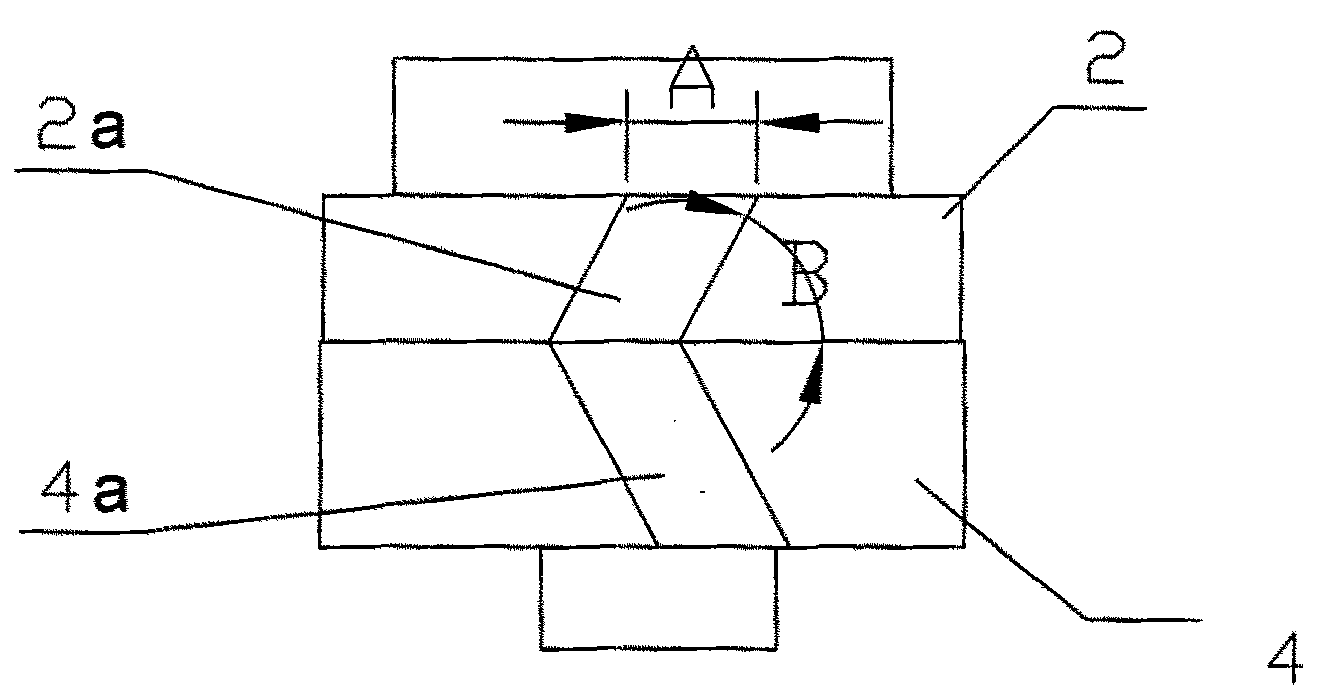

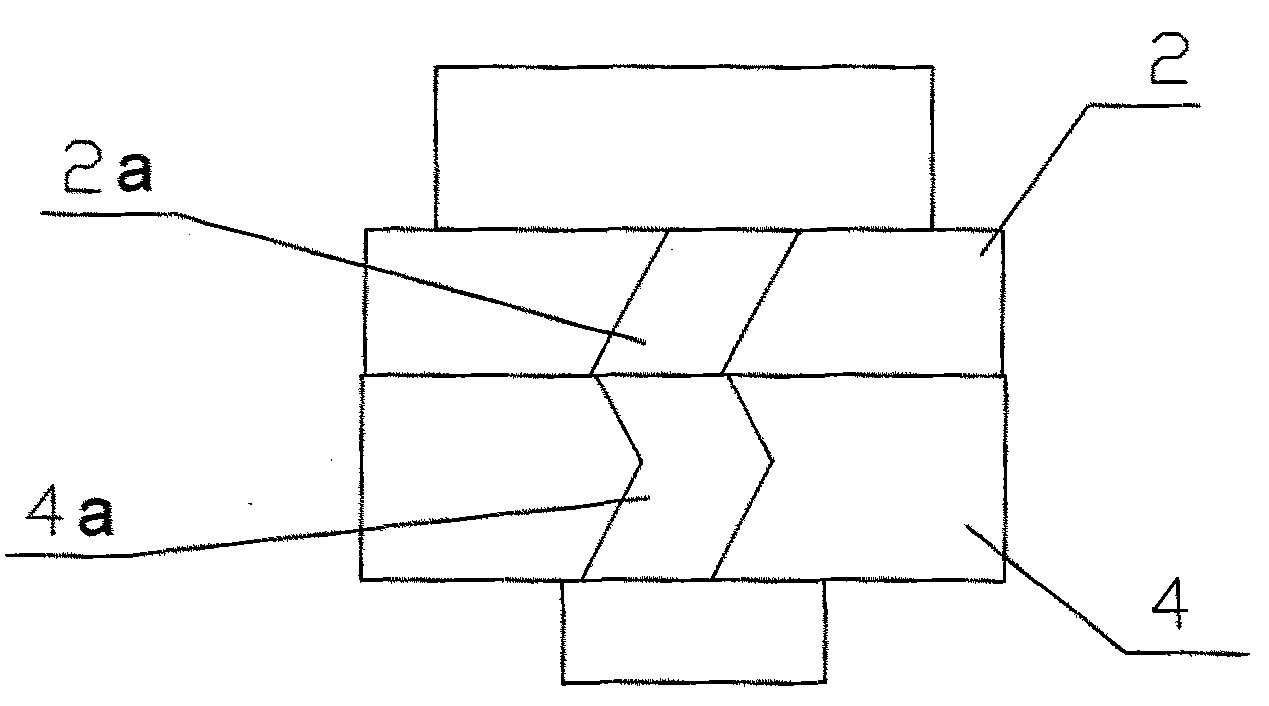

[0018] see figure 1 , the motor in the scroll compressor of the present invention drives the crankshaft 5 to rotate, and the crankshaft 5 drives the movable scroll 3 to revolve around the static scroll 2, so a series of crescents are formed between the movable scroll 3 and the static scroll 2 Space, as the crescent-shaped space in the outer circle moves toward the center, at this time, the refrigerant is gradually pushed to the center space, its volume shrinks and the pressure continues to rise, until it communicates with the exhaust channel 2a, the high-pressure and high-temperature refrigerant is exhausted Passage 2a discharges into the seal cavity of the scroll compressor.

[0019] exist figure 1 In , the solid arrows indicate the flow of refrigerant oil, and the hollow arrows indicate the flow of refrigerant. The mixed gas of refrigerating oil and refrigerant discharged from the exhaust passage 2a is guided between the bracket 4 and the motor parts through the gap betwee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Inclination | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap