Foam plastic machine hydraumatic station

A technology of hydraulic station and foam molding machine, which is applied in the direction of mechanical equipment, fluid pressure actuation device, fluid pressure actuation system components, etc., and can solve the problem that the hydraulic station of foam molding machine cannot meet the requirements of rapid feeding of the system. Problems such as poor energy saving effect of the station

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

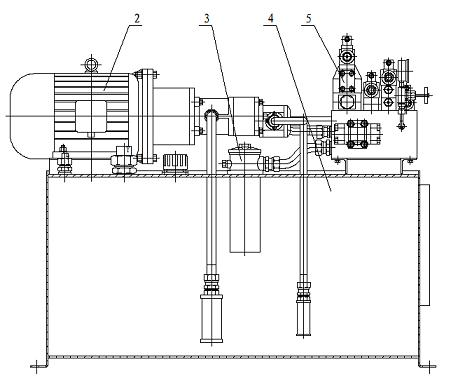

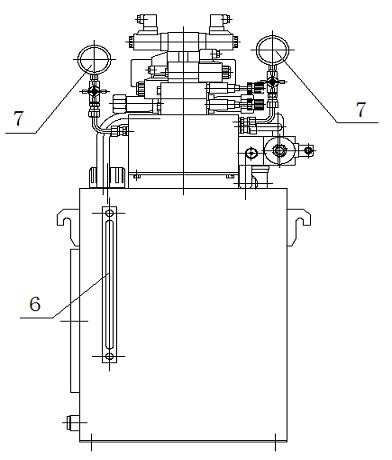

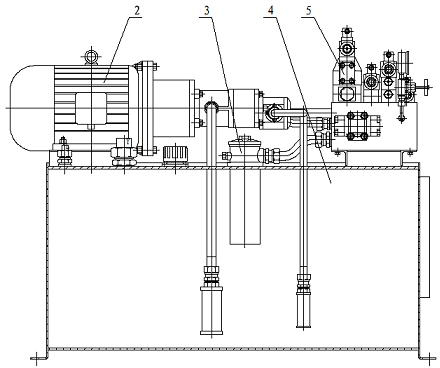

[0011] Such as figure 1 , figure 2 As shown, the hydraulic station of the foam molding machine includes the high oil tank control valve group 1, the power pump 2, the auxiliary components 3, the fuel tank 4 and the hydraulic station control valve group 5, the high oil tank control valve group 5, the power pump 2, and the auxiliary components 3 and the control valve group 5 of the hydraulic station are arranged on the top of the oil tank 4, the power pump 2 is connected to the control valve group 5 of the hydraulic station through pipelines, the auxiliary component 4 is connected to the control valve group 5 of the hydraulic station, and the side wall of the oil tank 4 is installed with a liquid level Meter 6, the power pump 2 is equipped with a pressure gauge 7, the flow of the pump is consistent with the flow required by the speed of the actuator, the hydraulic system of the foam molding machine makes the flow of the hydraulic pump only half of the flow required by the speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com