Chain

一种链条、链板的技术,应用在链条领域,能够解决增加磨损、发热噪音、张力不均衡等问题,达到抑制磨损增加、提高耐久性、抑制弯曲的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Hereinafter, the chain in the Example of this invention is demonstrated based on drawing.

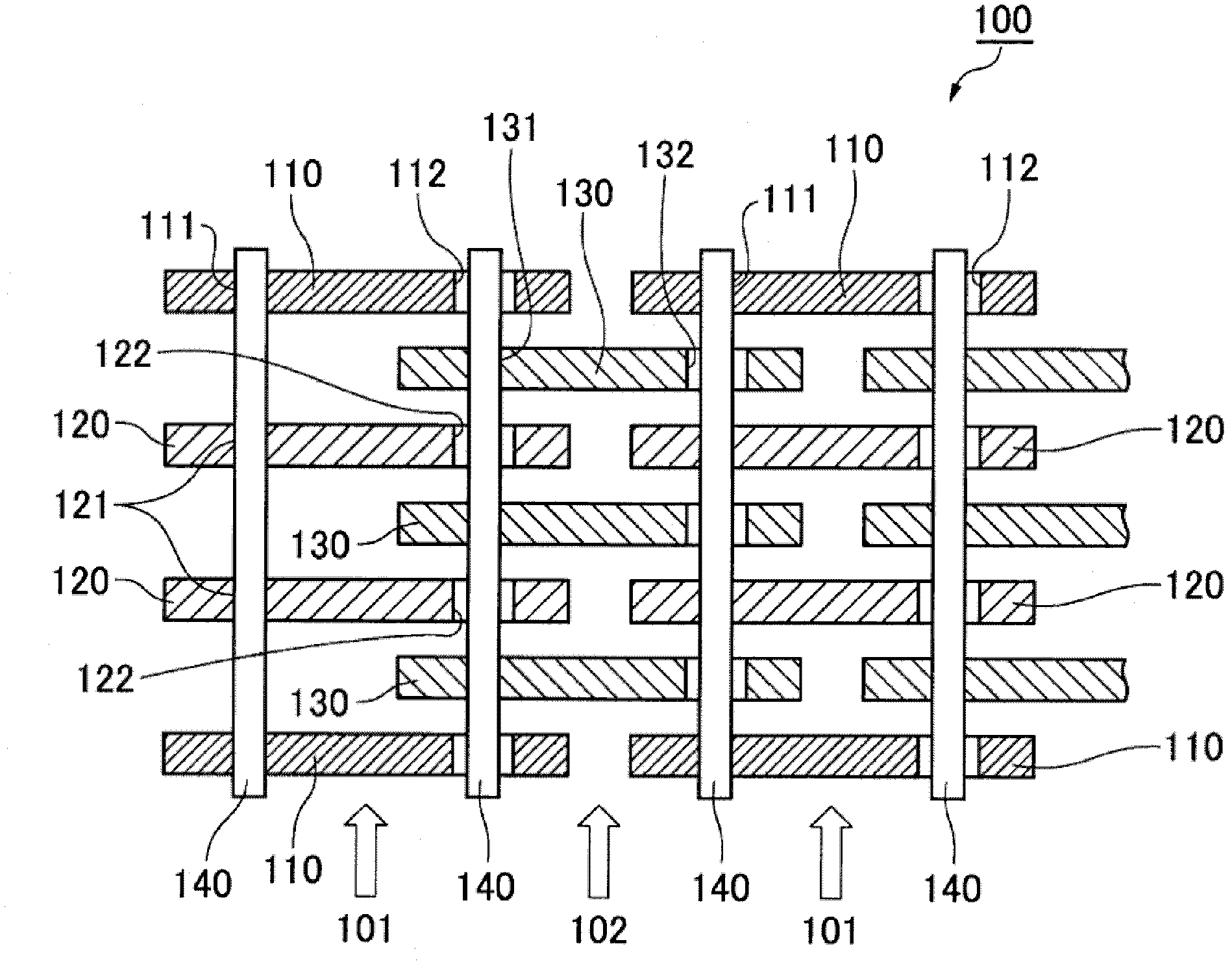

[0061] The chain 100 of the first embodiment of the present invention, as figure 1 As shown, a pair of guide chain plates 110 are arranged on the two outer sides of the width direction of the guide chain link row 101, and an intermediate chain plate 120 is arranged between the pair of guide chain plates 110 of the guide chain link row 101. Disposed in column 102 are inner link plates 130 .

[0062] A pair of front and rear first pin holes 111 , 121 , 131 and second pin holes 112 , 122 , 132 are respectively provided on the guide link plate 110 , the middle link plate 120 , and the inner link plate 130 .

[0063] Through the first pin holes 111, 121 of the guide link plate 110 and the intermediate link plate 120 of the guide link row 101 and the second pin hole 132 of the inner link plate 130 of the non-guide link row 102, and the guide link row 101 The second pin holes 112, 12...

Embodiment 2

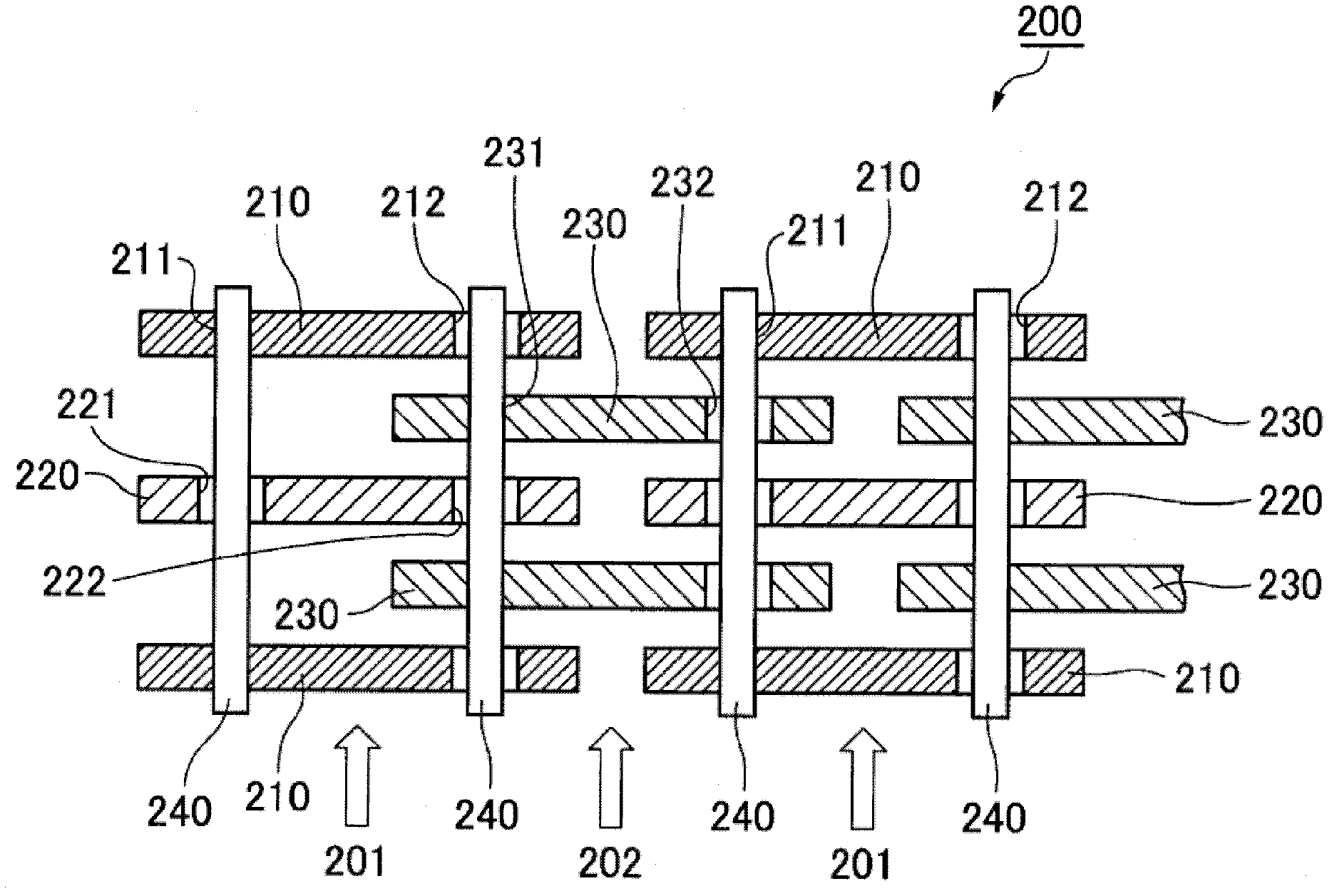

[0072] The chain 200 of the second embodiment of the present invention, as figure 2 As shown, a pair of guide chain plates 210 are arranged on both outer sides of the guide chain link row 201 in the width direction, and an intermediate link plate 220 is arranged between the pair of guide chain plates 210 of the guide chain link row 201. Disposed in column 202 are inner link plates 230 .

[0073] A pair of front and rear first pin holes 211 , 221 , 231 and second pin holes 212 , 222 , 232 are respectively provided on the guide link plate 210 , the middle link plate 220 , and the inner link plate 230 .

[0074] Through the first pin holes 211, 221 of the guide link plate 210 and the intermediate link plate 220 of the guide link row 201 and the second pin hole 232 of the inner link plate 230 of the non-guide link row 202, and the guide link row 201 The second pin holes 212, 222 of the guide chain plate 210 and the middle link plate 220 and the first pin hole 231 of the inner si...

Embodiment 3

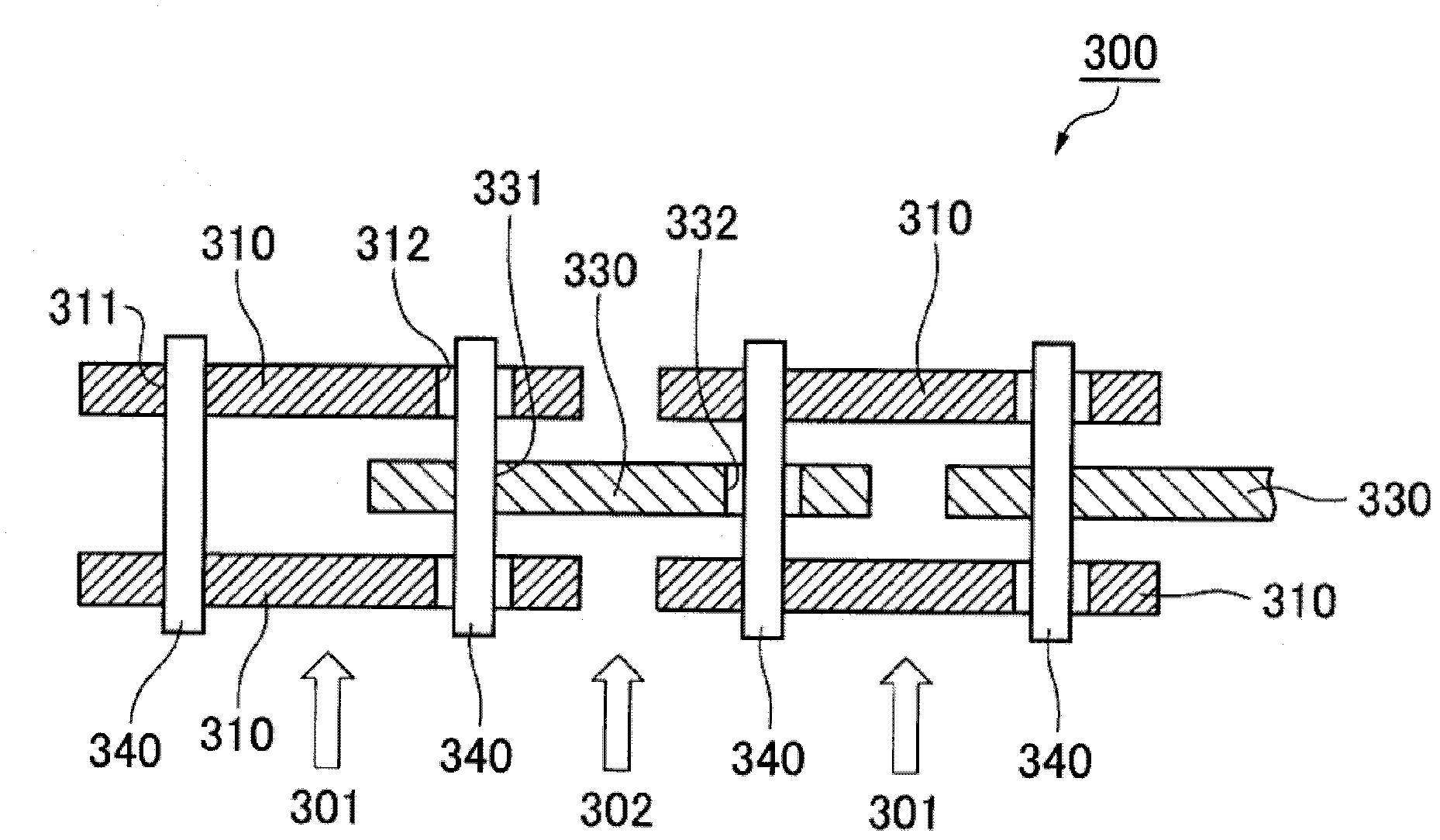

[0084] The chain 300 of the 3rd embodiment of the present invention, as image 3 As shown, a pair of guide link plates 310 are provided on both outer sides of the guide link row 301 in the width direction, and one inner link plate 330 is provided on the non-guide link row 302 .

[0085] A pair of front and rear first pin holes 311, 331 and second pin holes 312, 332 are provided on the guide link plate 310 and the inner link plate 330, respectively.

[0086] Pass through the first pin hole 311 of the guide chain plate 310 of the guide chain link row 301 and the second pin hole 332 of the inner side link plate 330 of the non-guide chain link row 302, and the first pin hole 332 of the guide chain plate 310 of the guide chain link row 301. 2. Connecting pins 340 are inserted through the pin holes 312 and the first pin holes 331 of the inner link plate 330 of the non-guide link row 302, respectively, so that the braided chain 300 is alternately connected.

[0087] The respective c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com