Gas pressure gauge with automatic pressure alarming function

A gas pressure and pressure technology, applied in the field of pneumatic system detection, can solve the problems of wide range of pipeline layout and troublesome pressure detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

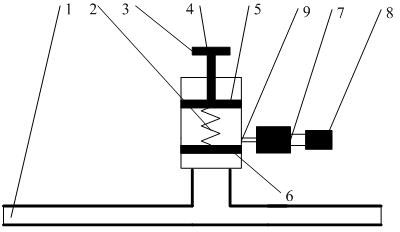

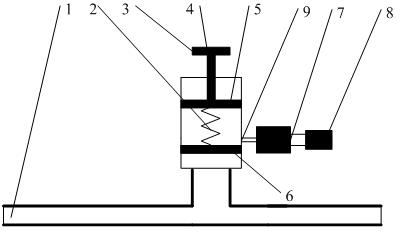

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below.

[0021] Connect the instrument in parallel to the pipeline, turn the knob to set the maximum pressure allowed in the pipeline, and the maximum pressure at this time corresponds to the spring preload. When the gas pressure is greater than the maximum pressure, the gas pushes the lower pressure plate (6), the gas in the pipeline flows out from the overflow hole (9), enters the gas amplifier (7), and finally drives the gas alarm (8) to alarm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com