Test system of gas vane carried engine hot commissioning

A test system and engine technology, applied in the field of test systems, can solve problems such as poor versatility, low measurement accuracy, difficulty in realizing complex test states and accurate simulation, and achieve the effects of accurate simulation, high measurement accuracy, and strong system versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

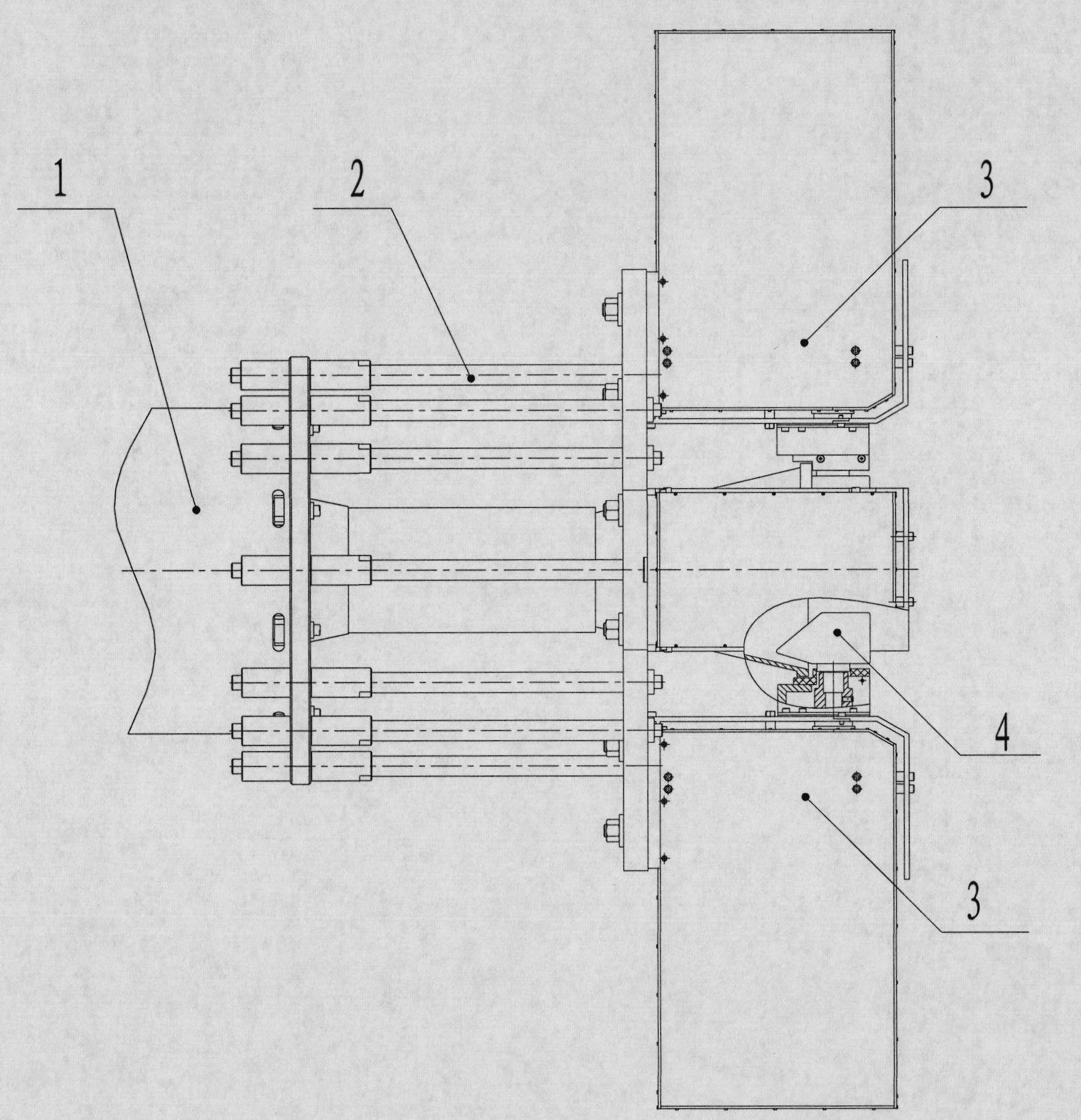

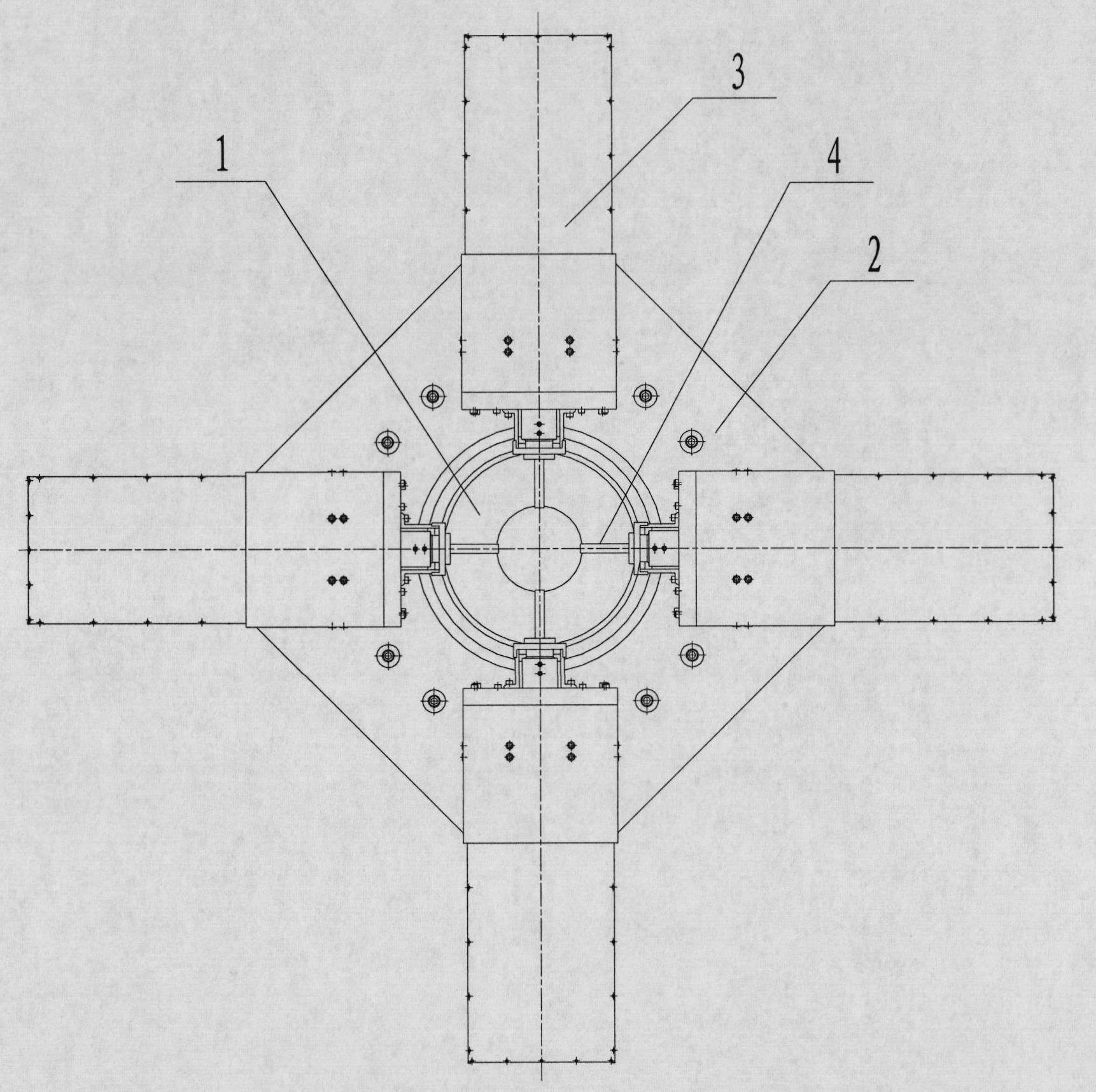

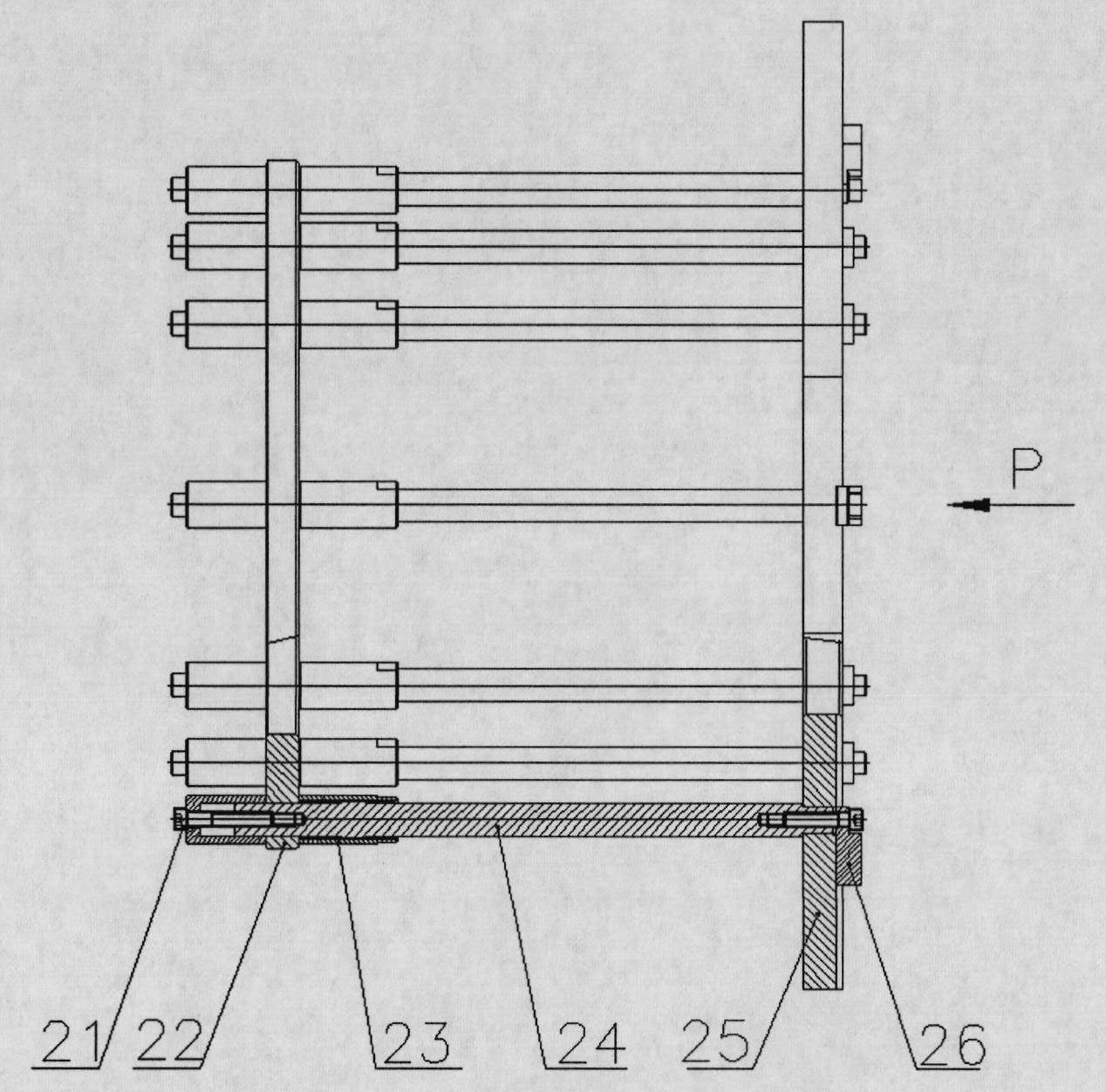

[0048] The invention relates to a test system for a thermal test run of an engine equipped with a gas rudder, which includes a mounting bracket and a force measuring device. The mounting bracket is connected with the end frame of the tail skirt of the engine, and is used to fix the force measuring device. It has the function of adjusting the axial and radial distance between the engine and the force measuring device, and realizes the positioning of the gas rudder relative to the engine nozzle, so that the flow of the gas rudder is The field is basically the same as that of the missile, and the force measuring device is suitable for engines of various sizes within a certain range. Multiple sets (usually four sets) of force measuring devices are installed on the installation end frame of the mounting bracket, and each set of force measuring devices is used to control the deflection of a piece of gas rudder in the jet flow of the engine according to the set requirements, and measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com