Testing machine for safety belt dust

A technology for seat belts and testing machines, applied in vehicle testing, mechanical component testing, machine/structural component testing, etc., can solve the problems of low reliability of seat belt use, poor test data consistency, and poor test results, etc. To achieve the effect of stable work, simple and compact structure and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

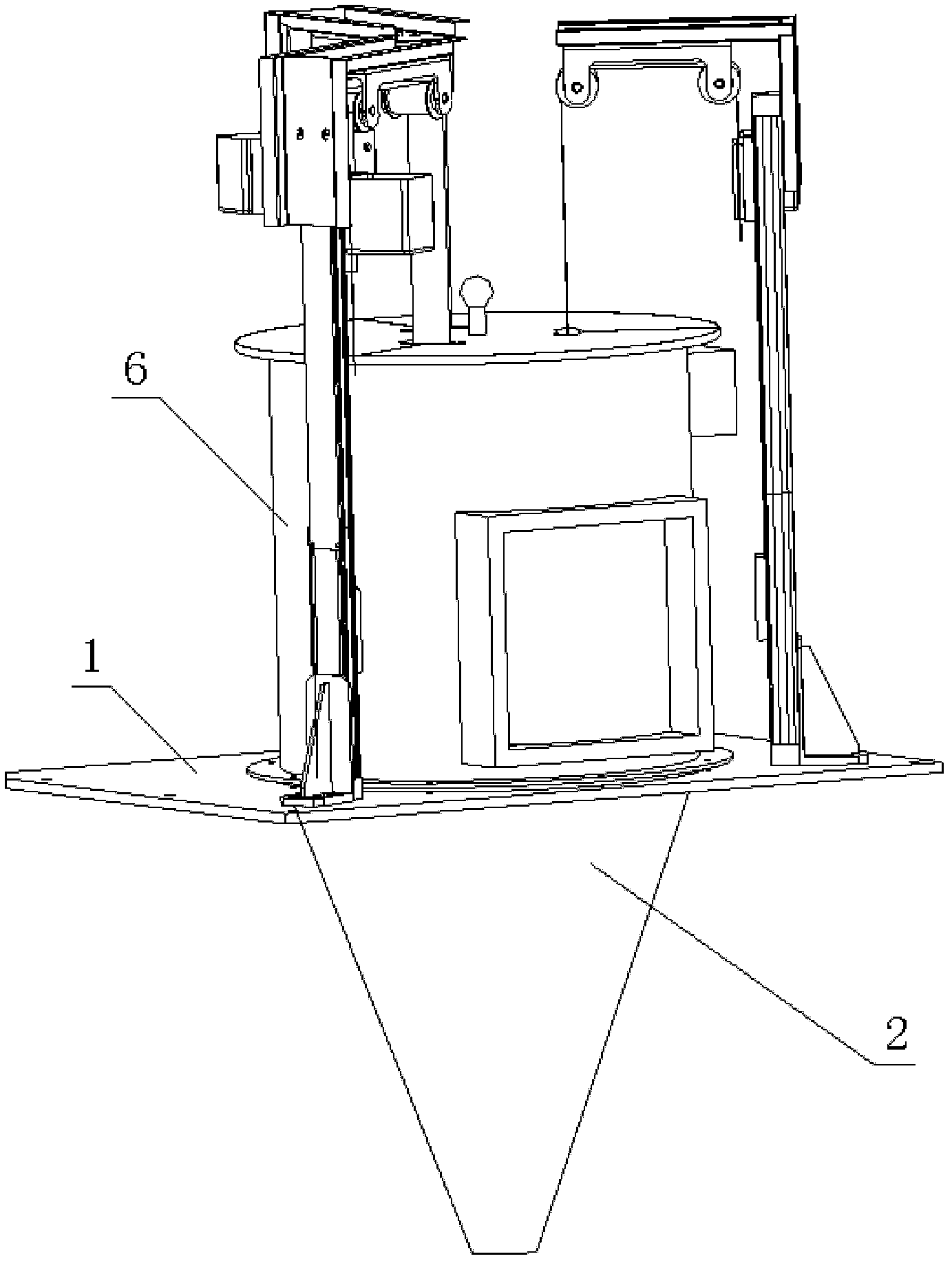

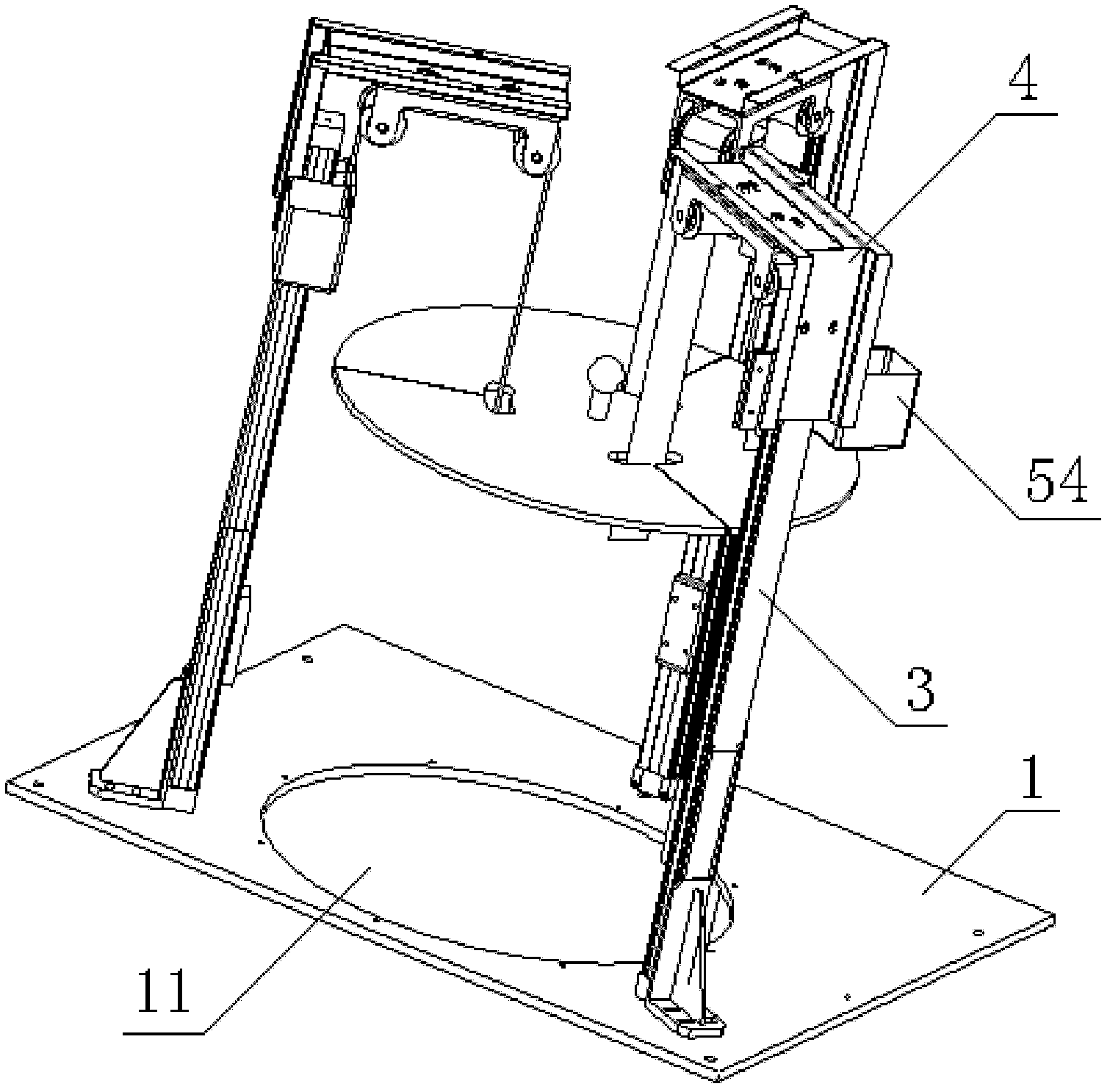

[0018] Depend on Figure 1-Figure 3 Combining the structures shown, it can be seen that this safety belt dust testing machine includes a working platform 1, a dust cylinder device 2 and a seat belt drive assembly. On the circumference of the working platform 1, the safety belt driving assembly is installed on the working platform 1 and evenly arranged on the periphery of the through hole 11; the safety belt driving assembly and the dust cylinder device 2 are located on both sides of the working platform 1 in the working state.

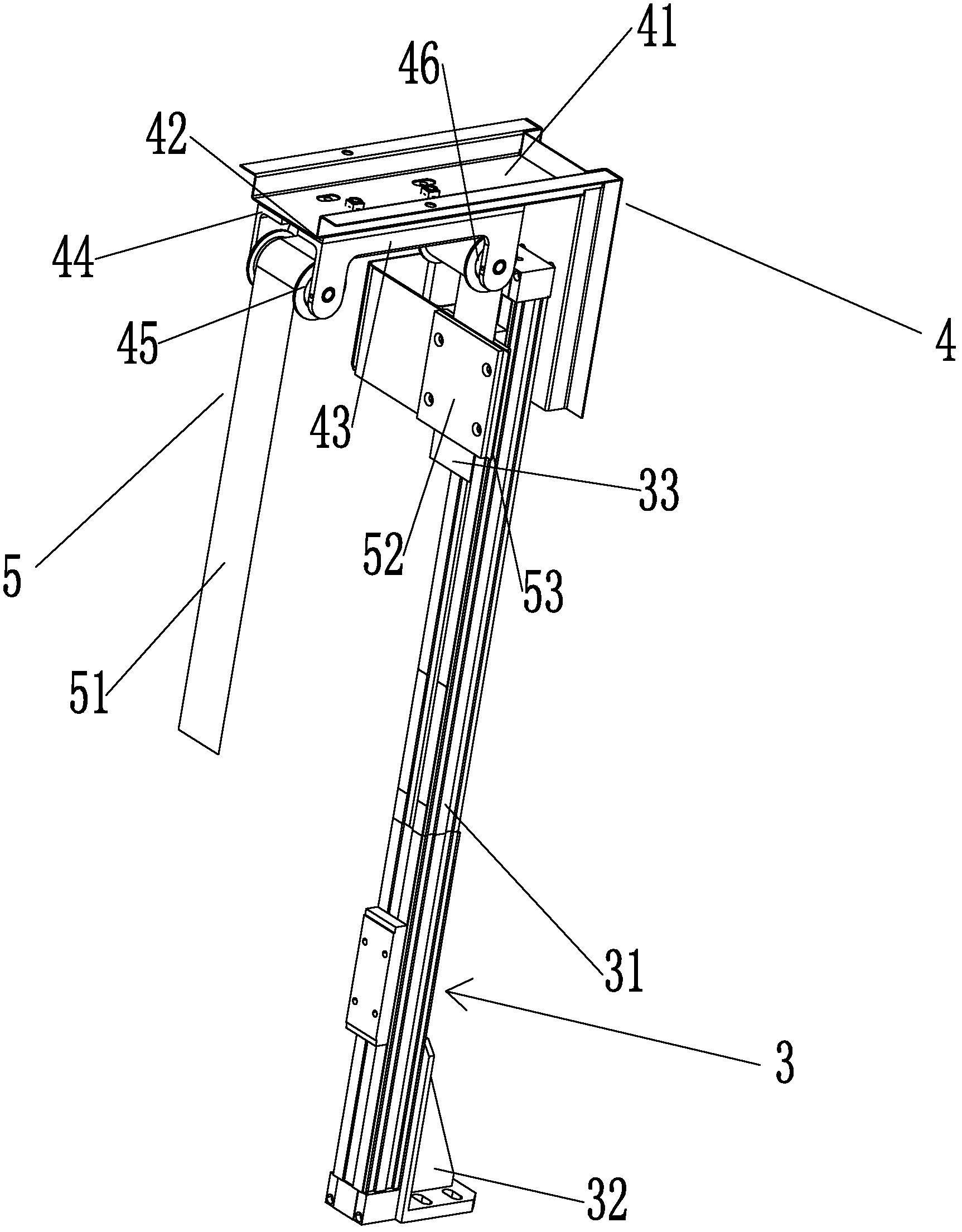

[0019] The seat belt driving assembly includes a cylinder assembly 3 , a pulley assembly 4 and a webbing assembly 5 . Cylinder assembly 3 comprises cylinder 31, cylinder bracket 32 and cylinder slider 33, and cylinder assembly 3 is fixed on the working platform 1 by cylinder bracket 32, and cylinder 31 and cylinder slider 33 are fixed on cylinder bracket 32, and cylinder slider 33 is fixed Above the cylinder 31; the pulley assembly 4 includes a pull...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com