Pull-off force test method

A test method and pull-off force technology, applied in the field of testing, to achieve the effect of no error, simple operation, and true and reliable data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the drawings.

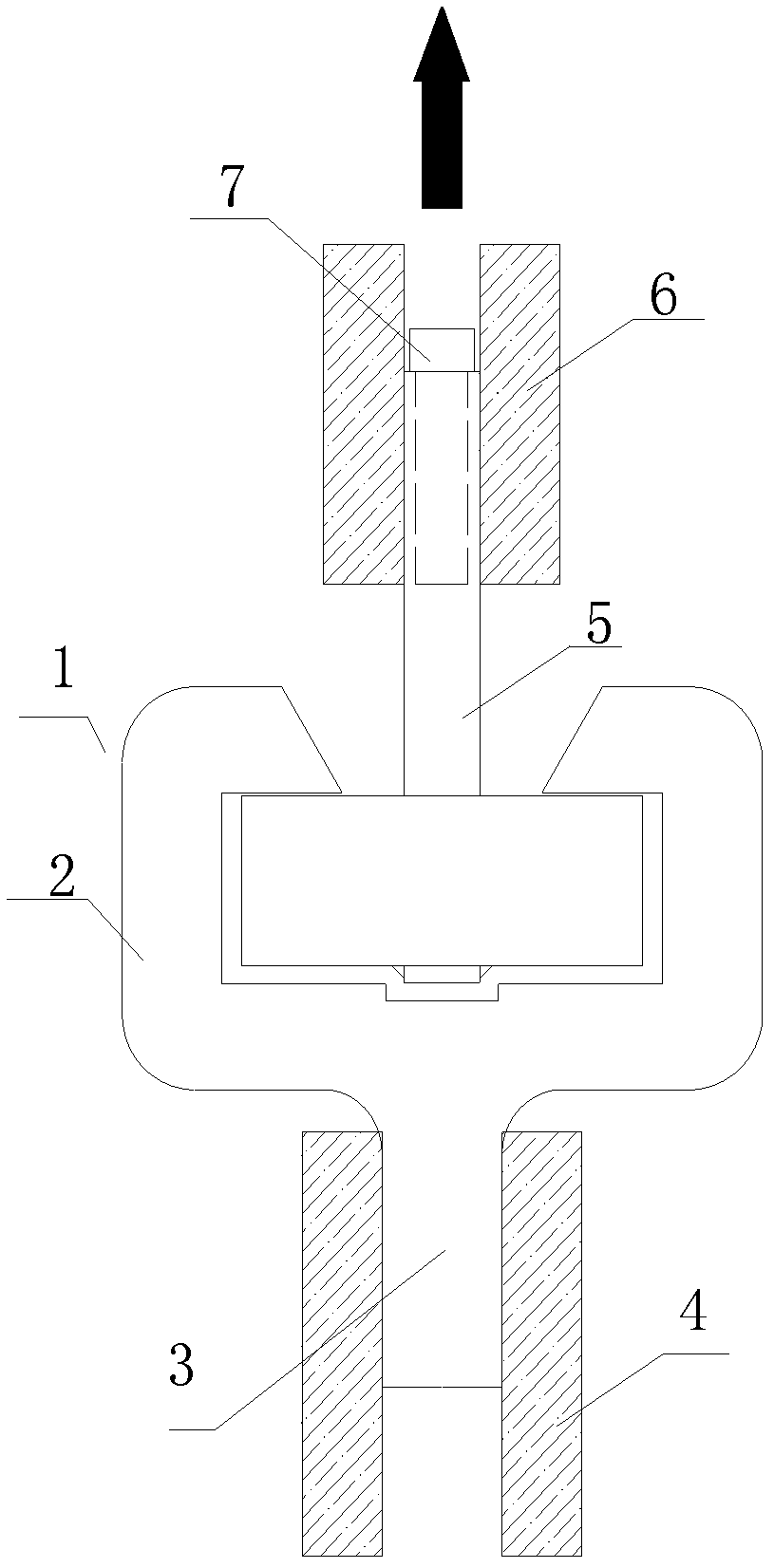

[0023] figure 1 It is a schematic diagram of the pull-off force test method in the present invention. In actual construction, the pipe fitting and the tube sheet are made by strength welding and expansion. After the production is completed, the welding process between the pipe fitting and the tube sheet joint must be evaluated to determine whether it meets the design requirements. Including heat exchange tubes, shunt tubes, etc. The pipe fittings in this embodiment adopt heat exchange tubes, and the method includes the following steps:

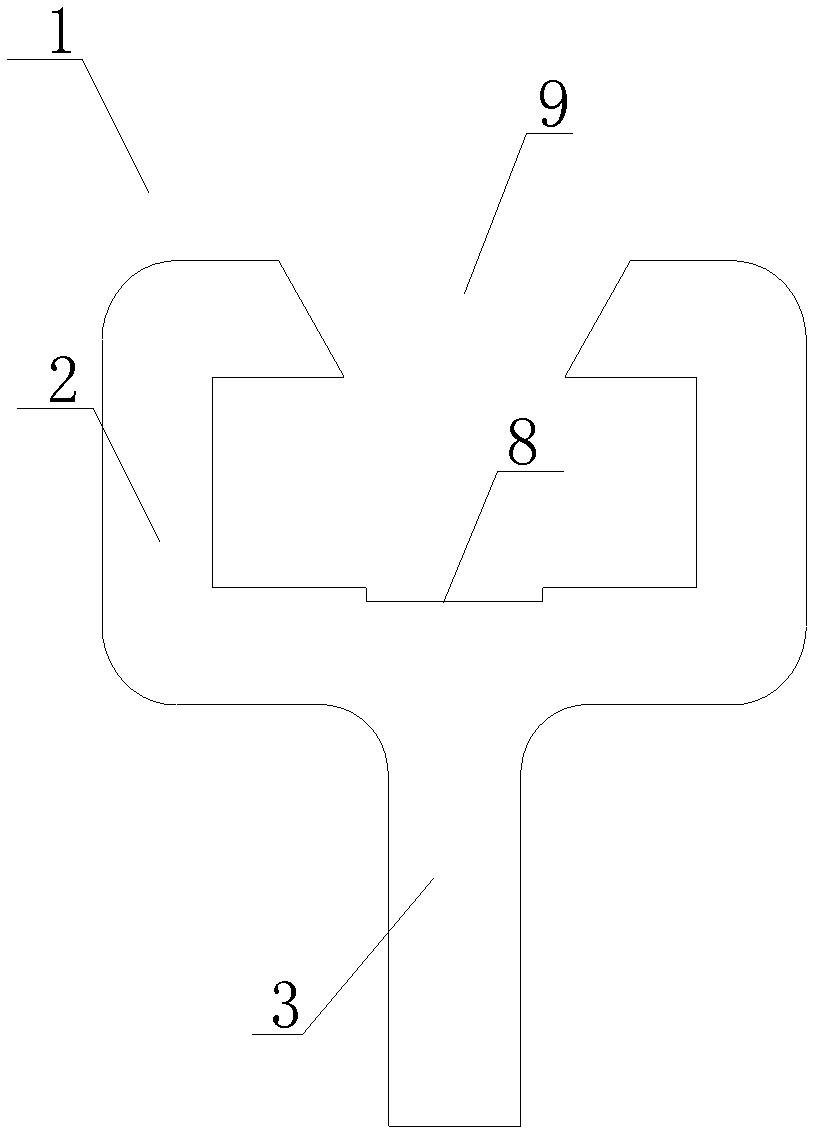

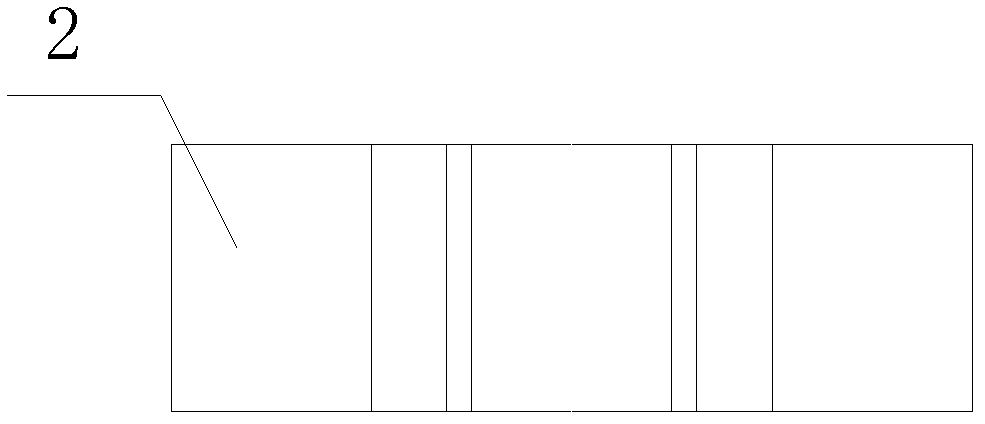

[0024] The first step is to process the test piece according to the drawing requirements. The test piece is as figure 1 with Figure 4 As shown, the test piece 5 includes a tube sheet 10 and a heat exchange tube 11. The tube sheet 10 is a rectangular parallelepiped. Five through holes are spaced along the length of the tube plate 10, and the heat exch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com