High-frequency reciprocating fretting friction and wear tester

A fretting friction and wear test technology, applied in the direction of testing wear resistance, measuring devices, instruments, etc., can solve the problems of not meeting the requirements of small load loading, poor adaptability, poor precision, etc., and achieve low power consumption and operation control accuracy The effect of high and low excitation current

Active Publication Date: 2013-07-17

济南益华摩擦学测试技术有限公司

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Existing friction and wear testing machines mainly include hydraulically loaded friction and wear testing machines, weight loading friction and wear testing machines, etc., but the loading methods of the above friction and wear testing machines are only suitable for loading large loads, and cannot be satisfied with The loading requirements of small loads, for the loading of small loads, its accuracy is poor and its adaptability is poor

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

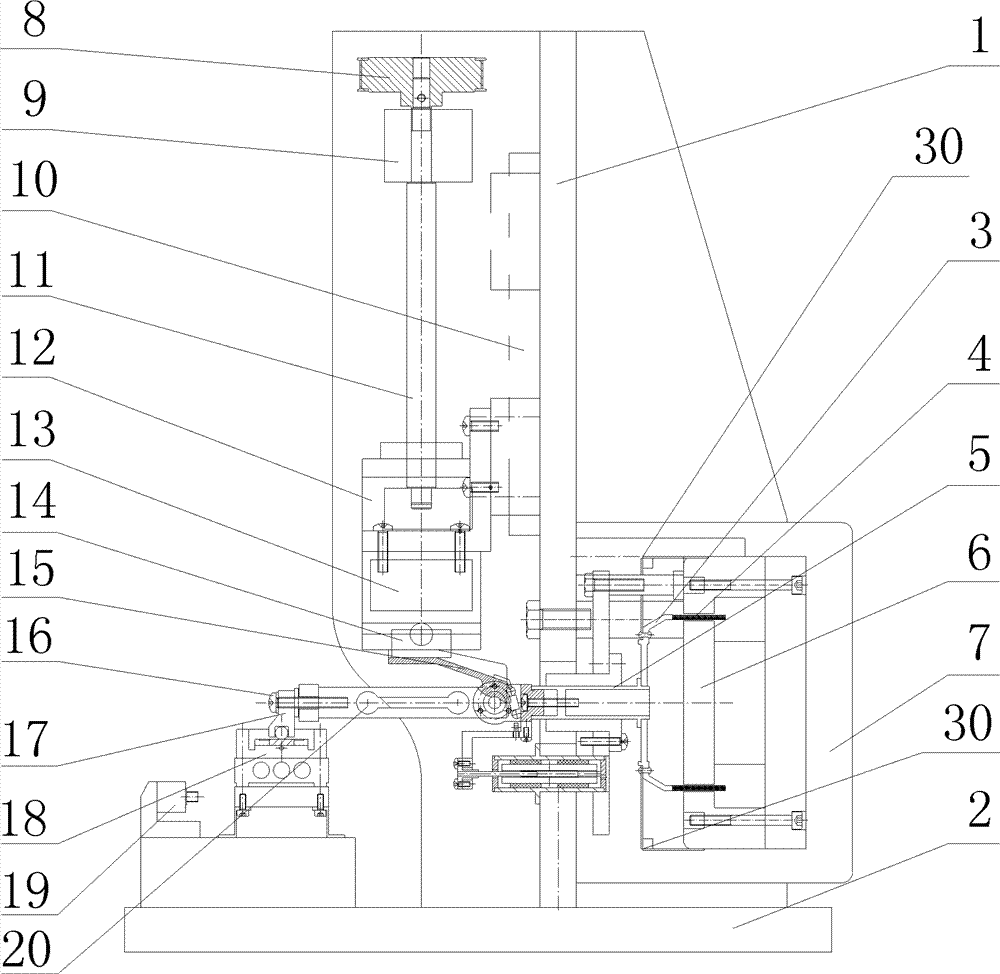

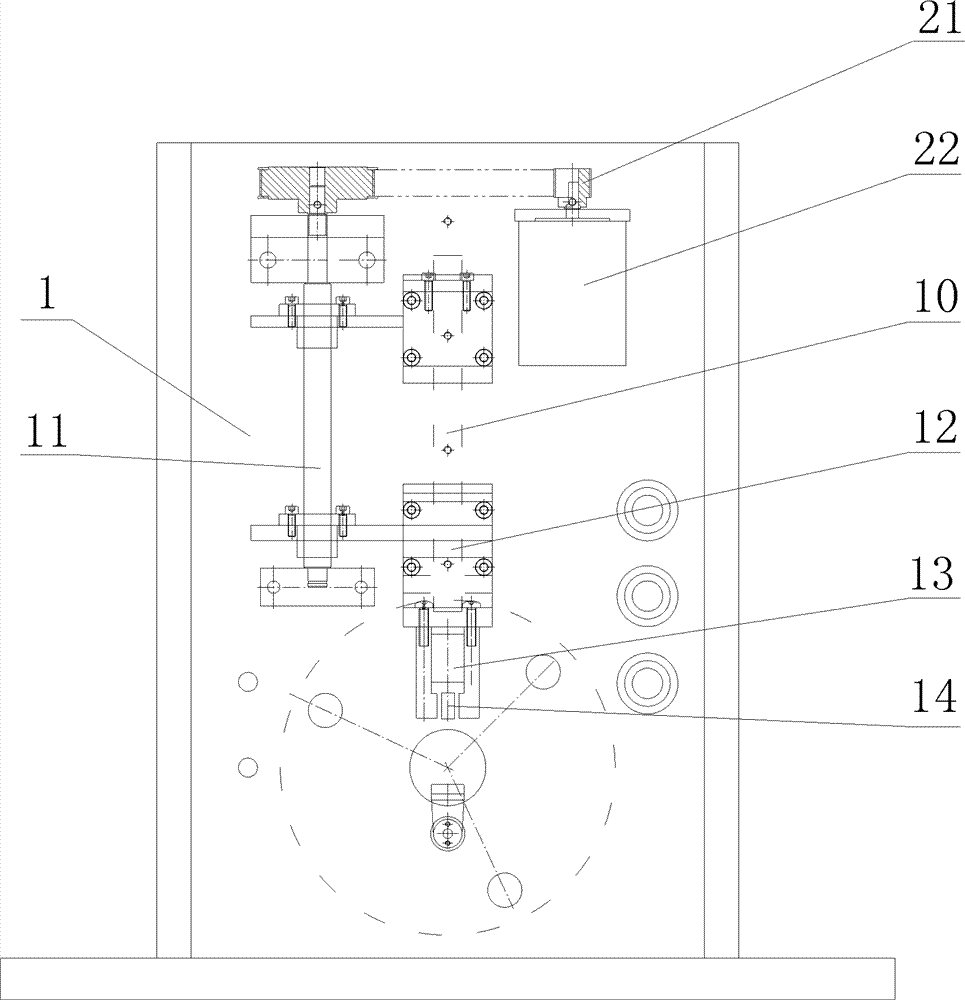

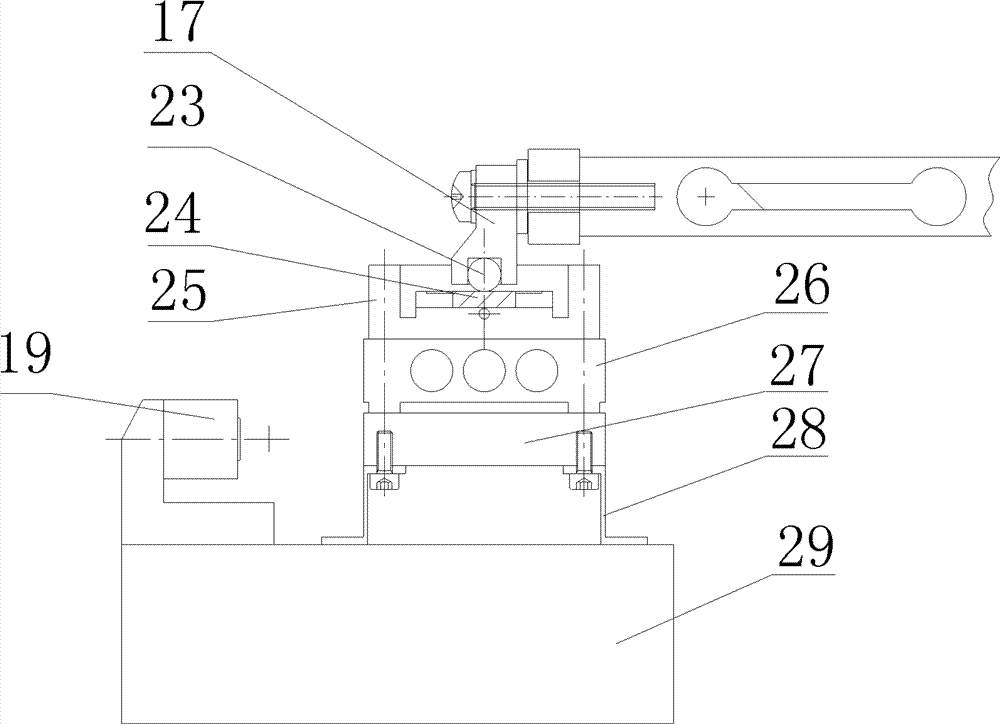

[0021] as attached Figure 1-3 As shown, a high-frequency reciprocating fretting friction and wear testing machine includes a reciprocating drive mechanism, a test force loading mechanism, a sample clamping mechanism, a signal acquisition and processing system, and an electrical control system.

[0022] The frame of the testing machine includes an upper base 1 and a lower base 2 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a high-frequency reciprocating fretting friction and wear tester, which is mainly used for fretting friction and wear tests. The high-frequency reciprocating fretting friction and wear tester comprises a reciprocating drive mechanism, a testing force loading mechanism, a sample clamping mechanism, a signal acquisition and processing system and an electrical control system,and is characterized in that: a testing force loading mode of the testing force loading mechanism is a magnetic loading mode. By the magnetic loading mode, the requirement for loading a small load ismet, and the tester can achieve higher testing accuracy.

Description

technical field [0001] The invention relates to a high-frequency reciprocating friction and wear tester, which is a high-frequency reciprocating fretting friction and wear tester mainly used for fretting wear experiments. Background technique [0002] Wear is one of the forms of material damage and failure. In vibrating machinery, threaded connections, spline connections, and interference fit connections are prone to fretting wear. The mechanism of fretting wear is: the positive pressure between the friction surfaces makes the asperities on the surfaces adhere. Fretting wear can lead to material damage and failure. [0003] At present, in the research of new materials and new processes, in addition to the traditional testing of mechanical, physical and chemical indicators, the testing of friction and wear properties has gradually been widely used. [0004] High-frequency reciprocating friction and wear testing machine is an experimental instrument used to study the frictio...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01N3/56G01N3/02

Inventor 肖华程俊

Owner 济南益华摩擦学测试技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com