Loading force value calibrating method suitable for fatigue-testing machine and applied calibrating device

A technology of fatigue testing machine and calibration device, which is applied in the direction of measuring device, calibration/testing of force/torque/power measuring instrument, instrument, etc. It can solve the problems of inability to obtain accurate results and achieve accurate calibration results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

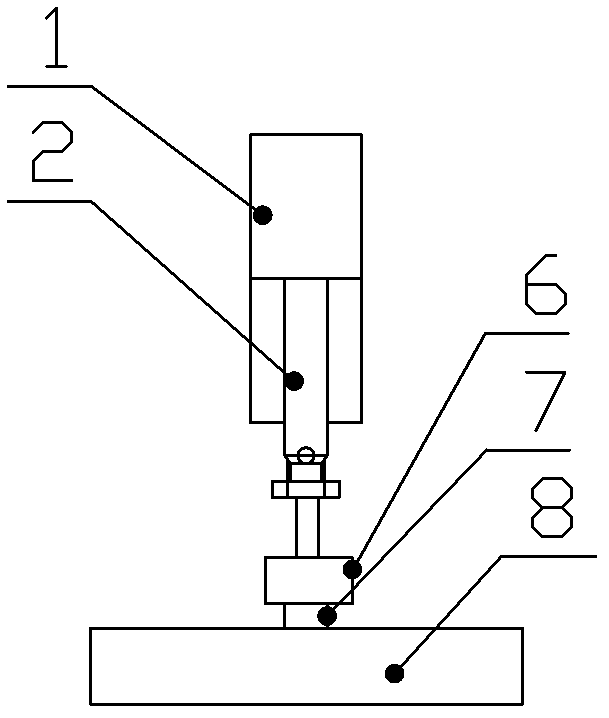

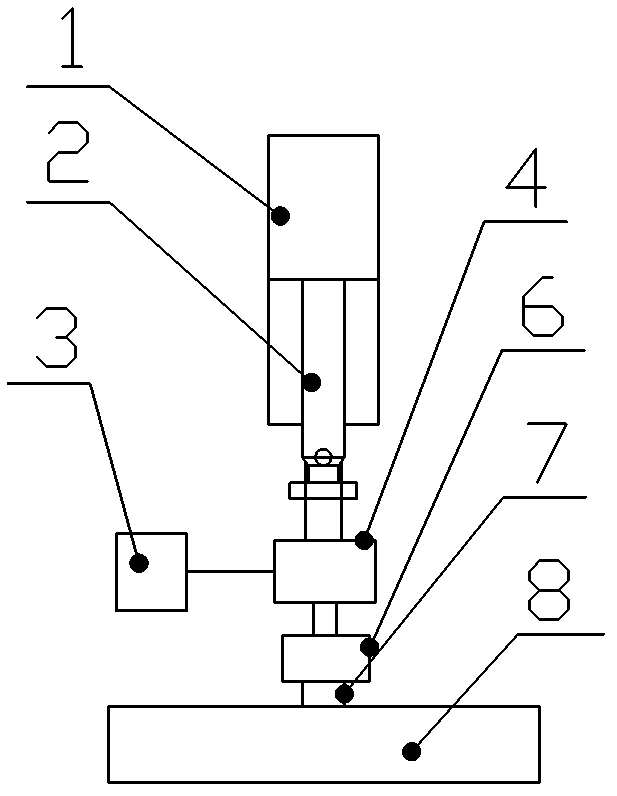

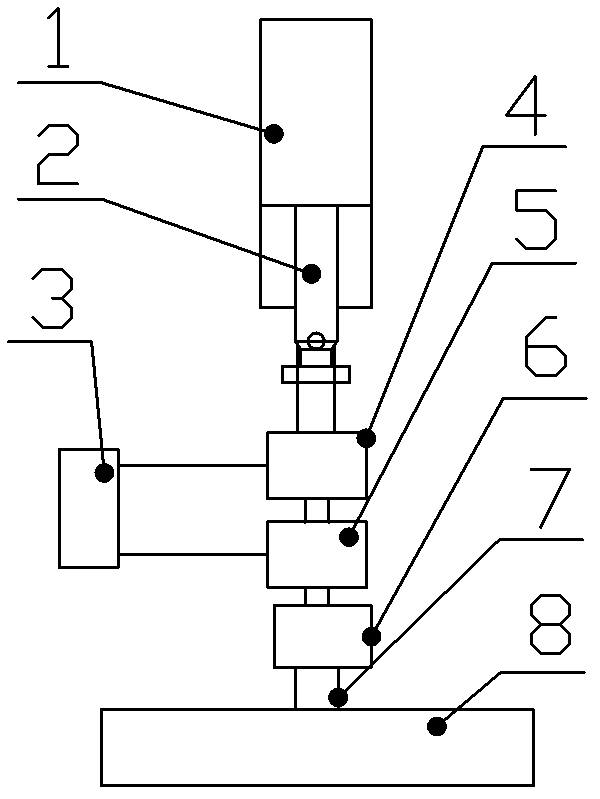

[0036] Embodiment 1, image 3 A calibration device suitable for the loading force value of a fatigue testing machine is given, including a cylinder 1 with a piston 2, a data acquisition system 3, a high-precision force sensor I4, a high-precision force sensor II5, a force sensor 6 and clamps Take fixture 7 of sample 8. High-precision force sensor I4 and high-precision force sensor II5 belong to exactly the same high-precision force sensor. All of the above components can be obtained through commercial purchase. For example, the high-precision force sensor I4 and the high-precision force sensor II5 can choose the precision force sensor (S type) produced by Bengbu Aerospace Sensing Measurement and Control Engineering Co., Ltd.

[0037]Between the piston 2 and the clamp 7, the high-precision force sensor I4, the high-precision force sensor II5 and the force sensor 6 are fixedly installed in sequence, the high-precision force sensor I4 is directly above the high-precision force ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com