Calibration method for oil-water relative permeability curve and oil displacing efficiency

A technology of relative permeability curve and oil displacement efficiency, which is applied in the direction of earthwork drilling and production, wellbore/well components, etc., which can solve the problems of prolonging experiment time, high cost, and increasing experiment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0051] The present invention proposes a calibration method of oil-water phase permeability curve and oil displacement efficiency, which comprises the following steps:

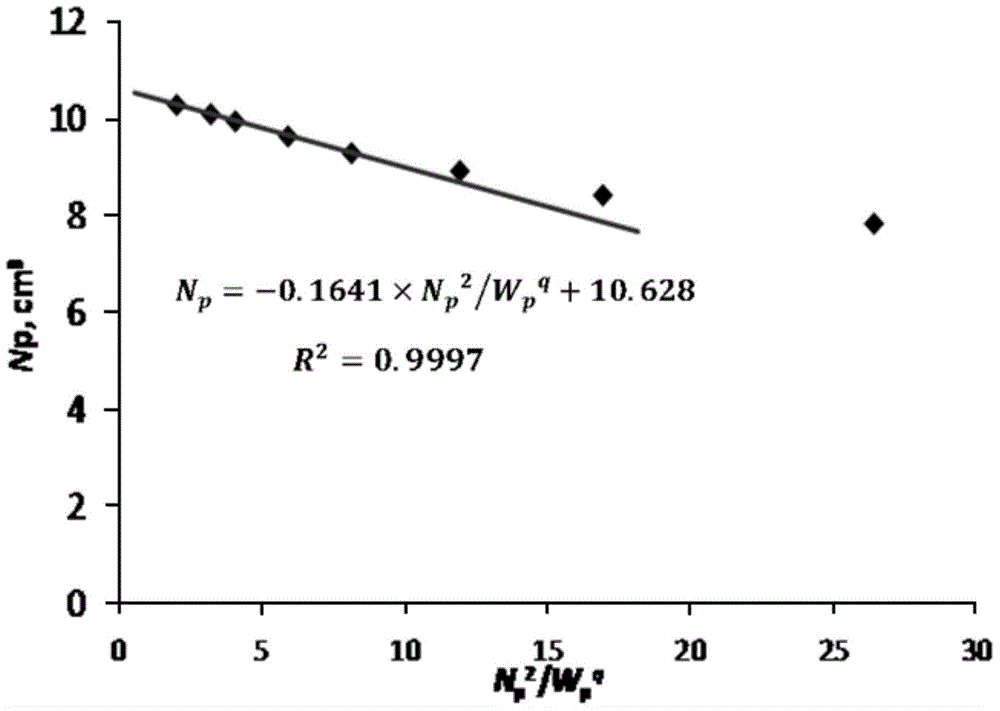

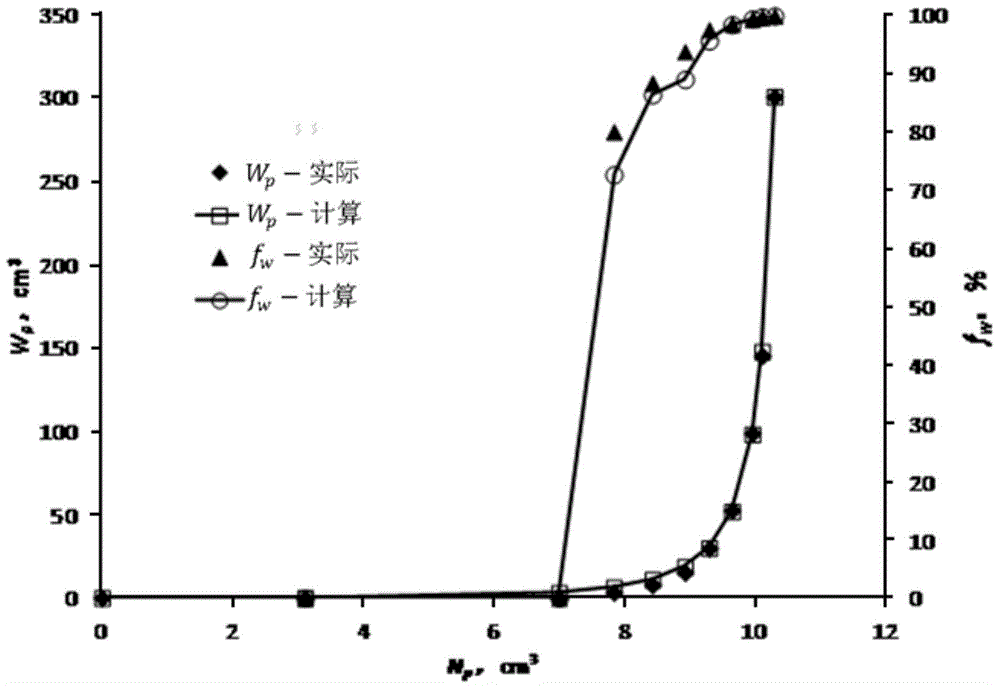

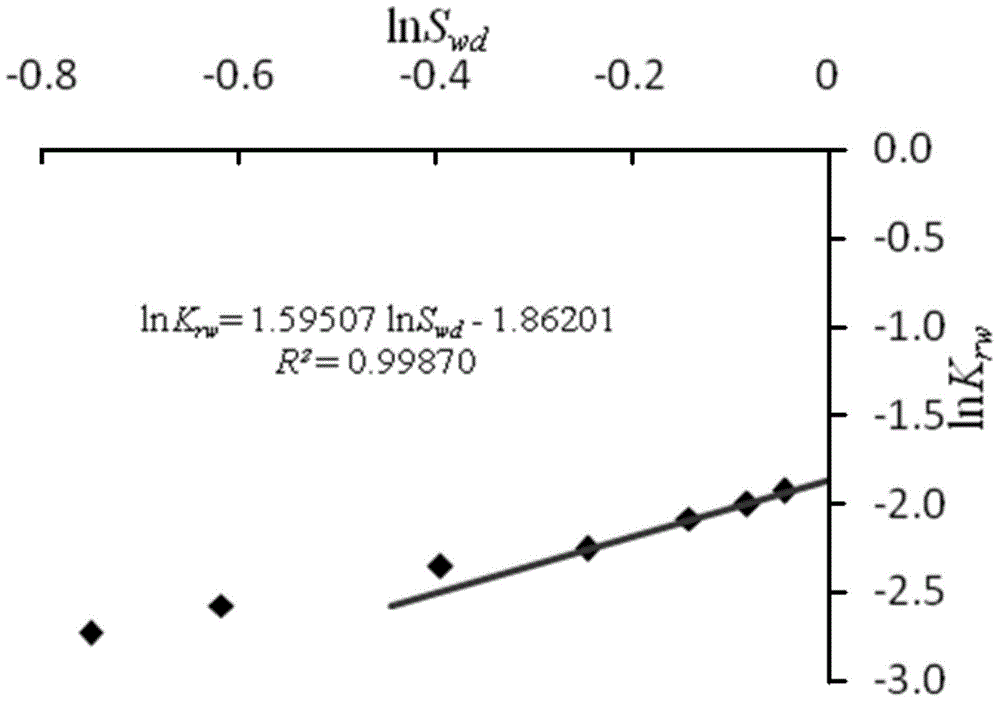

[0052] 1) In accordance with the industry standard "SY / T 6315-2006, Heavy Oil Reservoir High Temperature Relative Permeability and Oil Displacement Efficiency Determination Method", the indoor oil-water phase permeability physical simulation experiment was carried out, combined with the basis of oil-water phase permeability experiment parameter, to obtain the stage oil production Q at different sampling time t o , Stage water production Q w , water content f w , Cumulative oil production N p , Cumulative water production W p and cumulative fluid production L p and other experimental data; draw the oil-water phase permeability curve before calibration according to the experimental ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com