Electromagnetic detection method for metal flaw

An electromagnetic detection and detection method technology, applied in the direction of material magnetic variables, etc., can solve the problems such as complexity and stability limit the application development of crack detection technology, inability to meet, detection accuracy and measurement depth influence, etc., to achieve good consistency and accuracy High performance and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

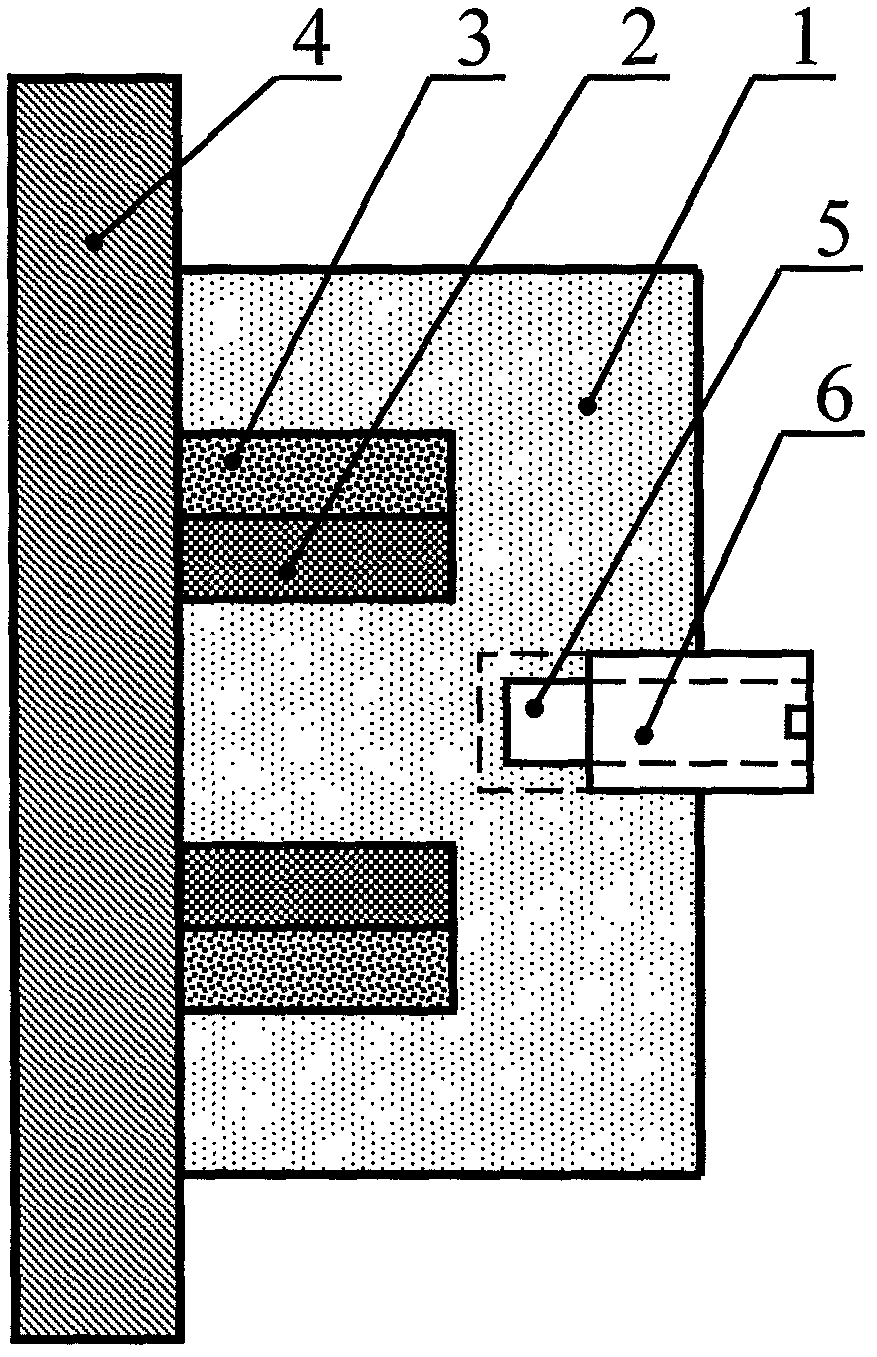

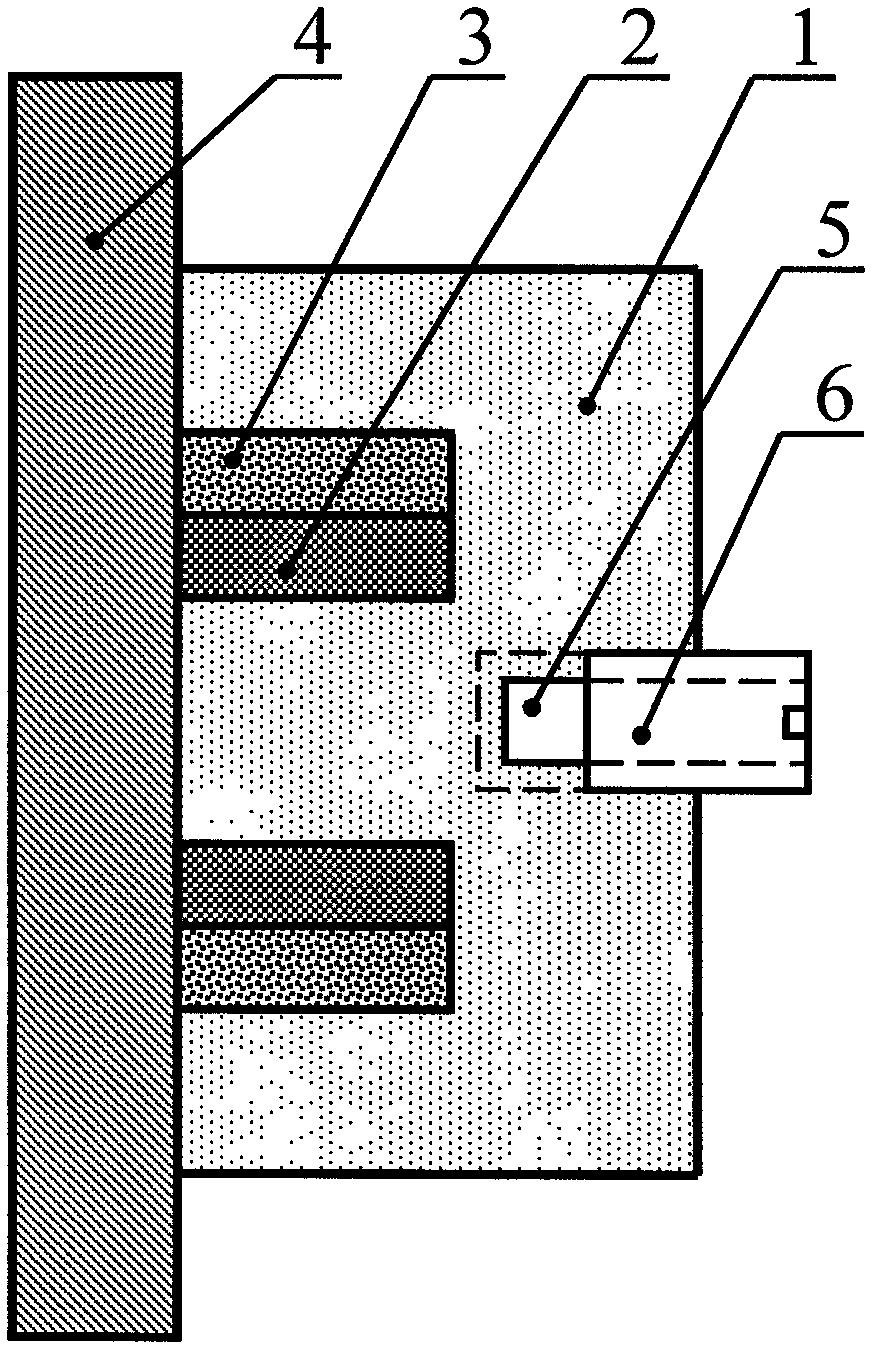

[0010] During the detection process, the combination of the E-shaped magnet 1 and the primary and secondary coils 2 and 3 is closely attached to the surface of the metal material, and the end surface of the magnet is kept in smooth and good contact with the measured part. Before testing, carry out zero point calibration: that is, to conduct a test on the same intact material to obtain the reference parameters. During the measurement, the same installation is carried out on the relevant parts of the metal material to be tested, and the voltage of the same parameter is added, and the corresponding voltage is induced by the secondary coil 3, and then processed by the detection circuit and calculation program, it automatically displays whether there is a crack. If there are cracks, the distribution, size and depth of the cracks can be determined by adjusting the change of the magnetic core bolts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com