Flat naked-eye 3D display lenticular screen and manufacturing method thereof

A technology of cylindrical lens grating and lens grating, which is applied in the field of flattening naked-eye 3D display cylindrical lens grating and its production, can solve the problems of cylindrical lens grating 3D display effect deterioration, difficulty, uneven periodic light field parallelism, etc., to achieve The effect of improving 3D display quality, simple manufacturing process, and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

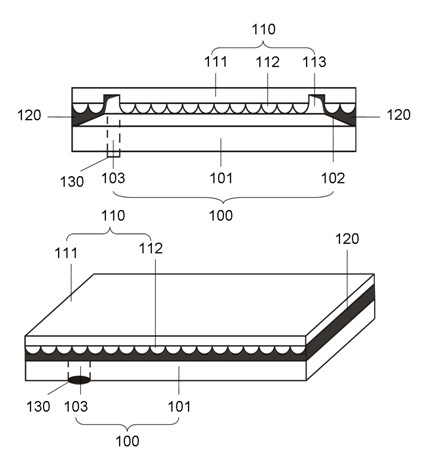

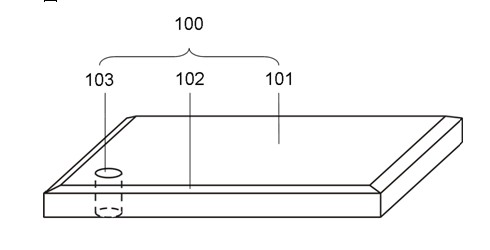

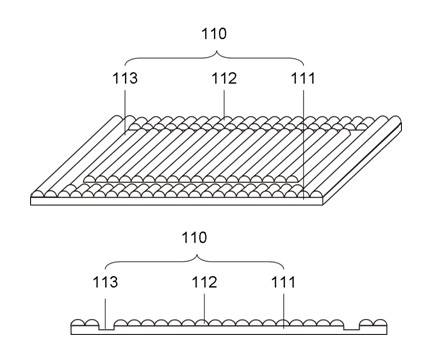

[0041] A manufacturing method for realizing flatness of a cylindrical lens grating for a naked-eye 3D display of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. The present invention provides preferred embodiments, but should not be construed as limited to the embodiments set forth herein. In the drawings, the thicknesses of layers and regions are exaggerated for clarity, but should not be construed as strictly reflecting the proportional relationship of geometric dimensions as a schematic.

[0042] The drawings referenced herein are schematic illustrations of idealized embodiments of the invention, and the illustrated embodiments of the invention should not be considered limited to the particular shapes of the regions shown in the drawings, but include resulting shapes, such as manufacturing-induced deviation. All are represented by rectangles in this embodiment, and the representation in the figure is sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com