Three-station solid insulating fully-sealed switch grounding mechanism

A solid insulation and fully sealed technology, which is applied in the direction of grounding device, switchgear, switchgear setting, etc., can solve the problems of increasing the cost of the ring main unit, misoperation of the operating mechanism, and large overall volume, and achieves compact structure and reduced volume. Small, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

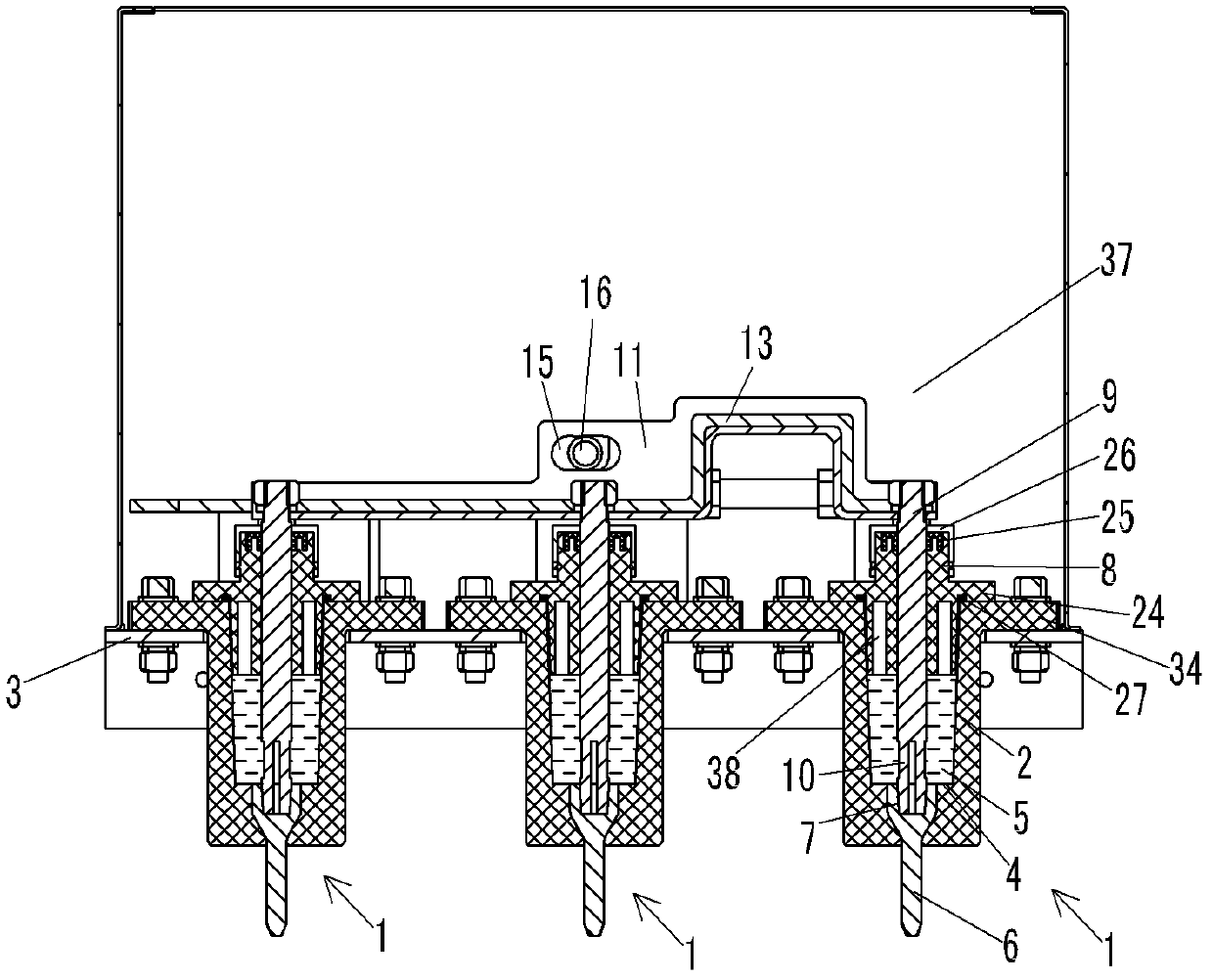

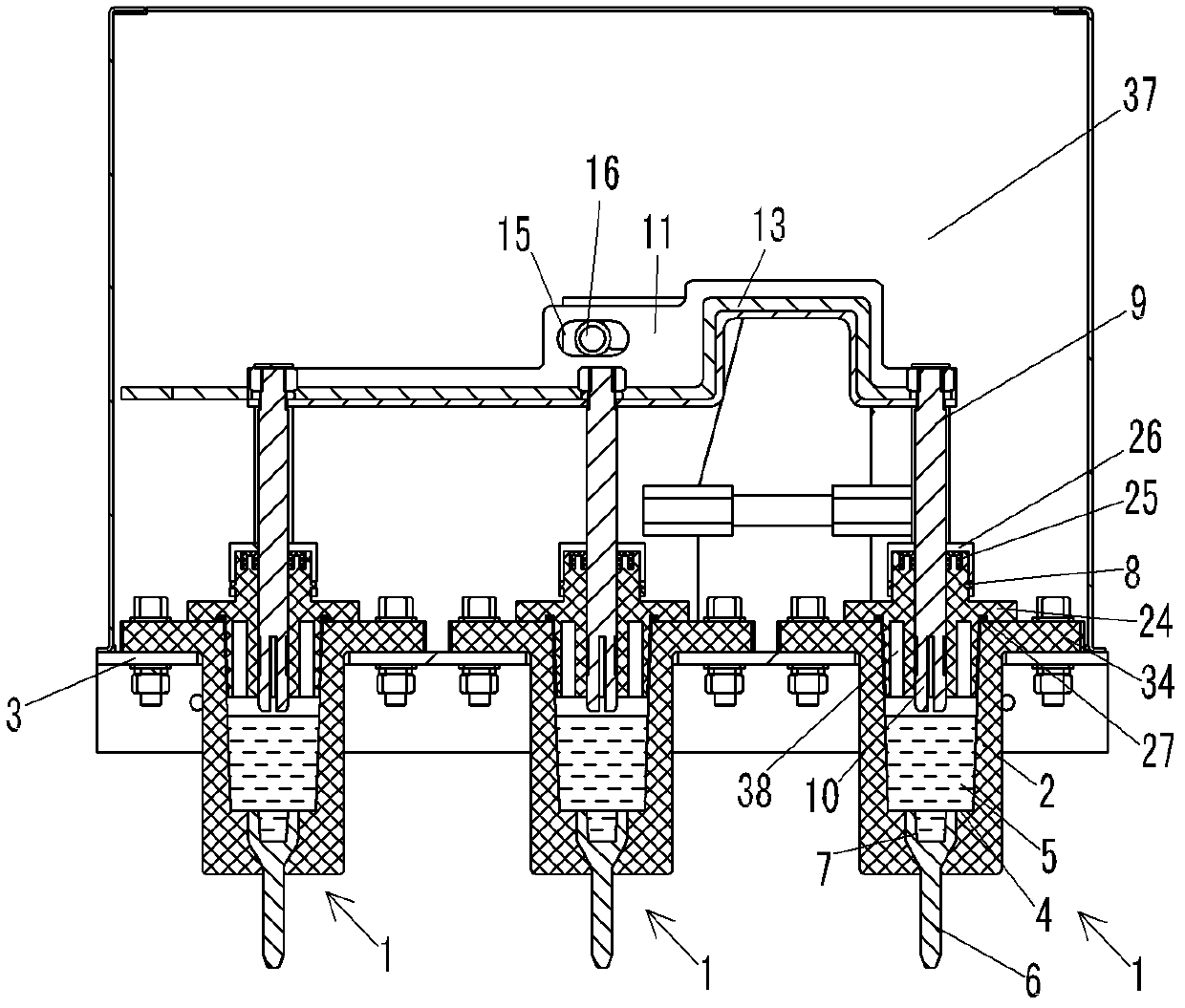

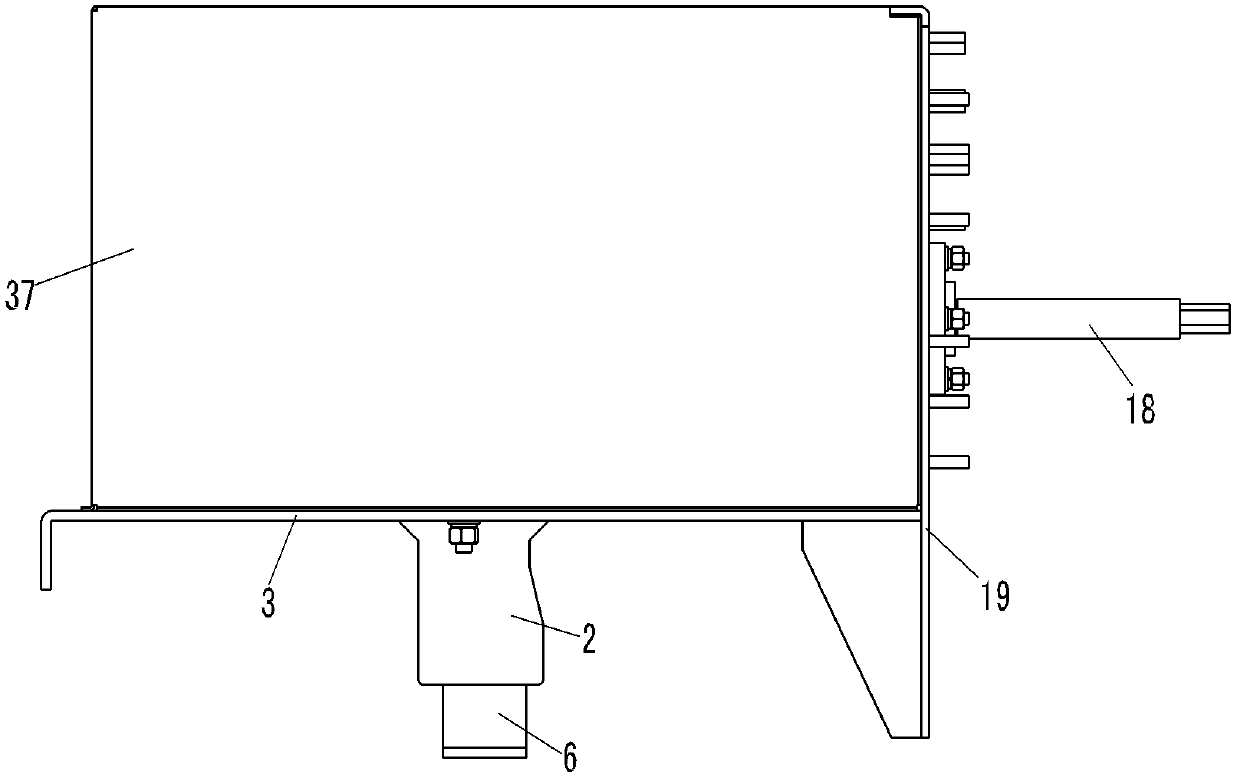

[0022] See Figure 1 to Figure 5 As shown, the grounding mechanism of the three-station solid-insulated fully sealed switch of the present invention includes three grounding pole devices 1 installed on the transmission box 37. Each grounding pole device 1 includes an insulating body 2 made of epoxy resin, a contact 6, a flange assembly 8, a grounding rod 9, an oil seal 25 and a sealing cover 26. The insulating body 2 is inserted through and fixed on the mechanism support plate 3 of the transmission box 37, combined with Image 6 with Figure 7 As shown, the upper end of the insulating body 2 is processed with an opening slot 4 extending into the lower part of the insulating body 2, and the opening slot 4 is filled with insulating oil 5, which can make the grounding mechanism reach a safe enough insulation distance between the charged bodies in the open state . The bottom of the insulating body 2 is fixedly sealed with the contact 6, the upper end of the contact 6 extends into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com