Vapor Phase Growth Device

A vapor phase growth and component technology, applied in electrical components, gaseous chemical plating, coatings, etc., can solve the problems of increased raw material gas usage, limited number of rotating bases, etc., to achieve the effect of increasing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

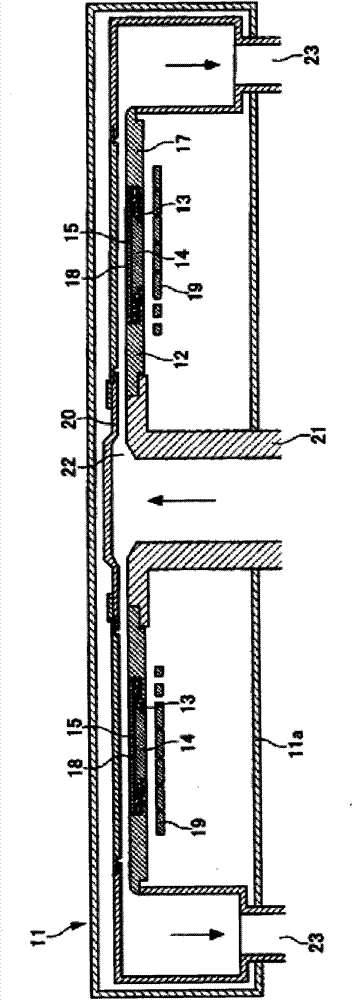

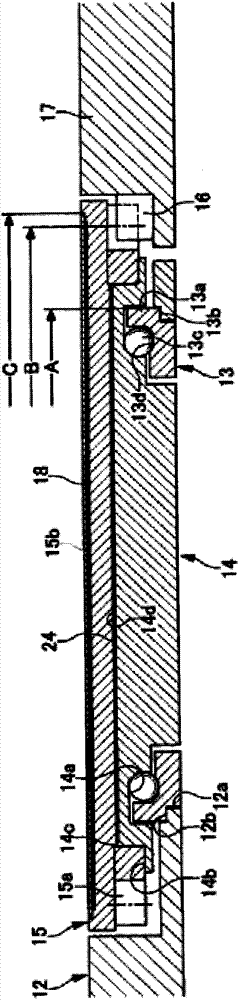

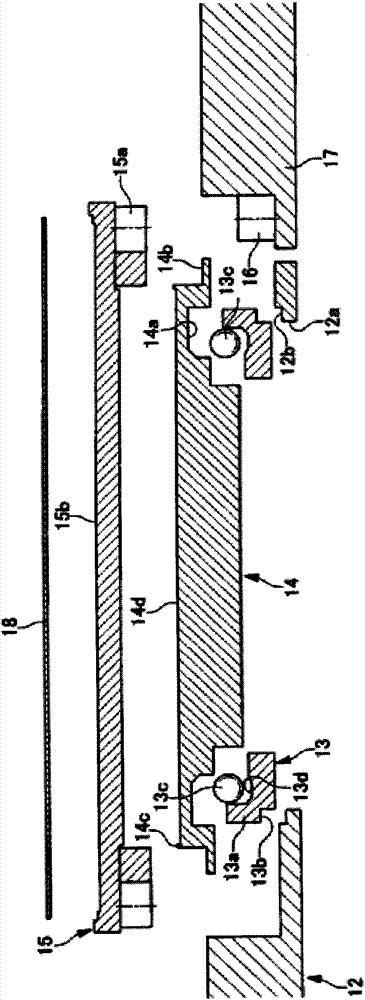

[0015] The gas-phase growth device shown in this embodiment is provided with a disc-shaped base 12 that can be rotatably arranged in a chamber 11, and the gas-phase growth device includes: annular bearing members 13, which are respectively arranged along the In a plurality of circular openings 12a formed in the circumferential direction of the outer peripheral portion of the base 12; a disc-shaped heat soaking plate 14, which is respectively rotatably mounted on each bearing member 13; an external gear member (rotation base) ) 15, which are respectively placed on each vapor chamber 14; an annular fixed internal gear member 17, which has an internal gear 16 meshing with the external gear member 15; The back side of the seat 12 heats the substrate 18 held on the surface of the above-mentioned external gear member 15 ;

[0016] A hollow shaft member 21 is provided at the center of the above-mentioned base 12. The hollow shaft member 21 extends downward of the base 12 and penetrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com