Spray fluxer device

A spray type and applicator technology, which is applied in the direction of spray devices, welding equipment, printed circuit coatings, etc., can solve the problems of inability to ensure the reliability of printed circuit boards, the reduction of foaming flux applicators, and poor burrs. Achieve the effects of preventing poor bridging, shortening the coating time, and increasing the coating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

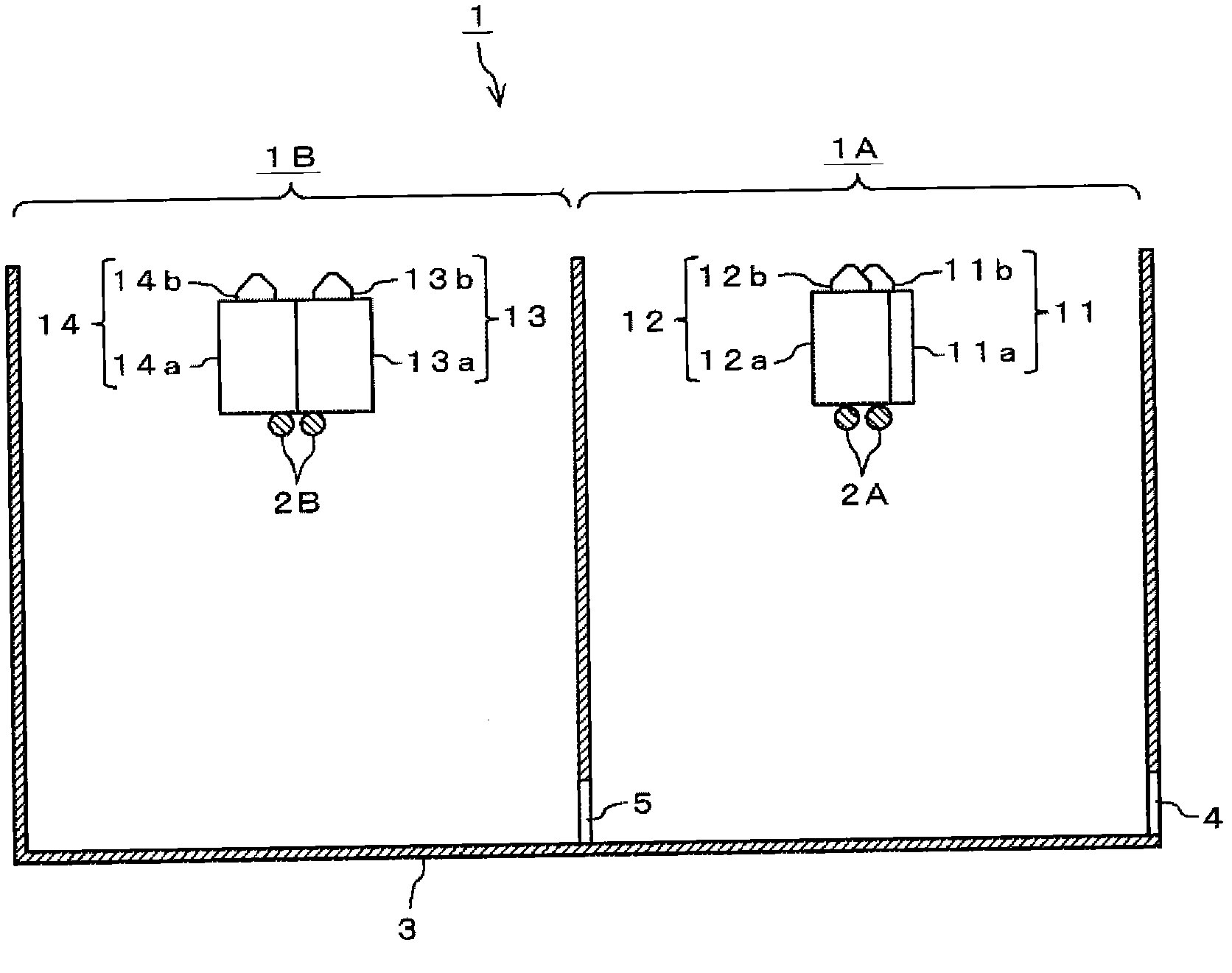

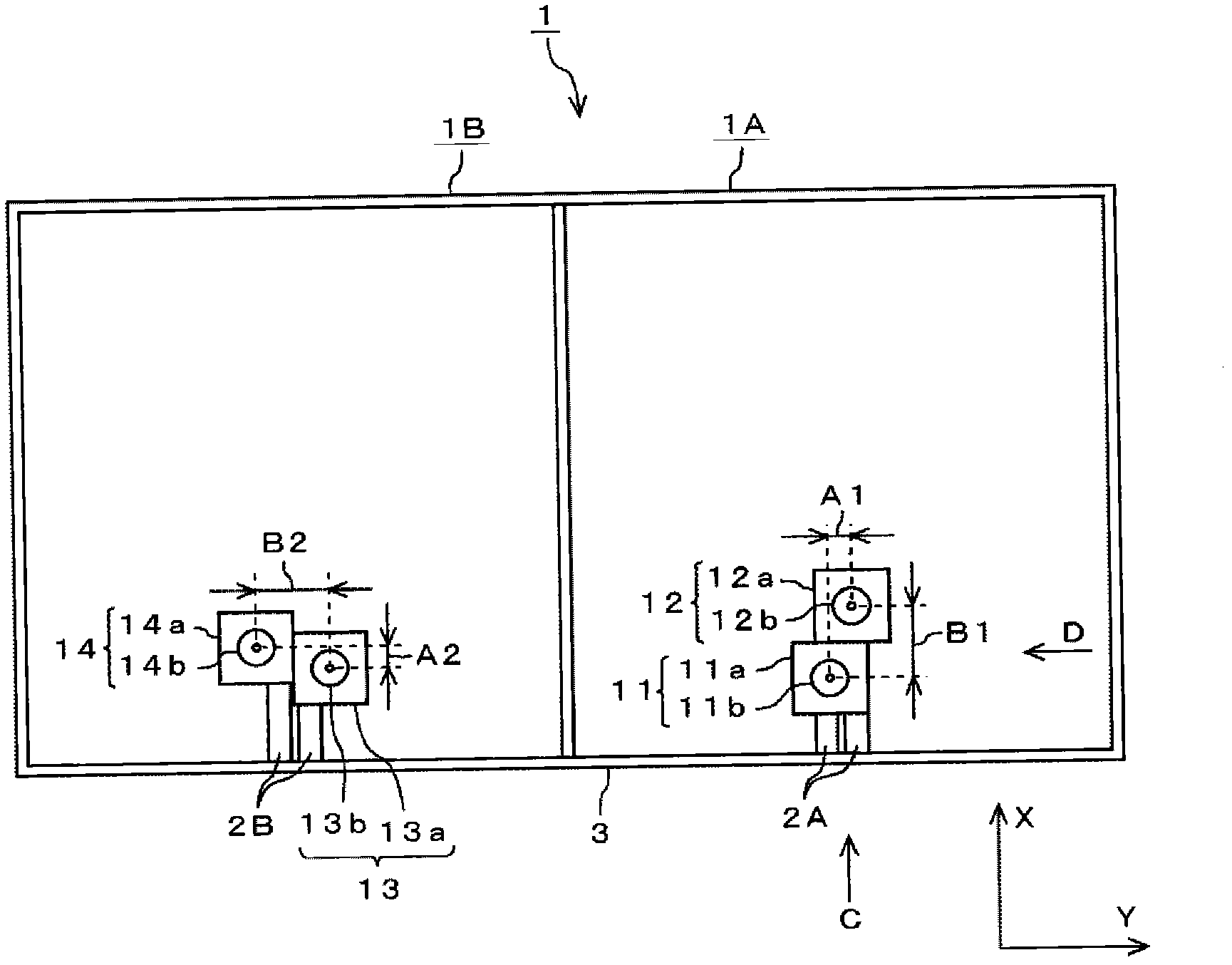

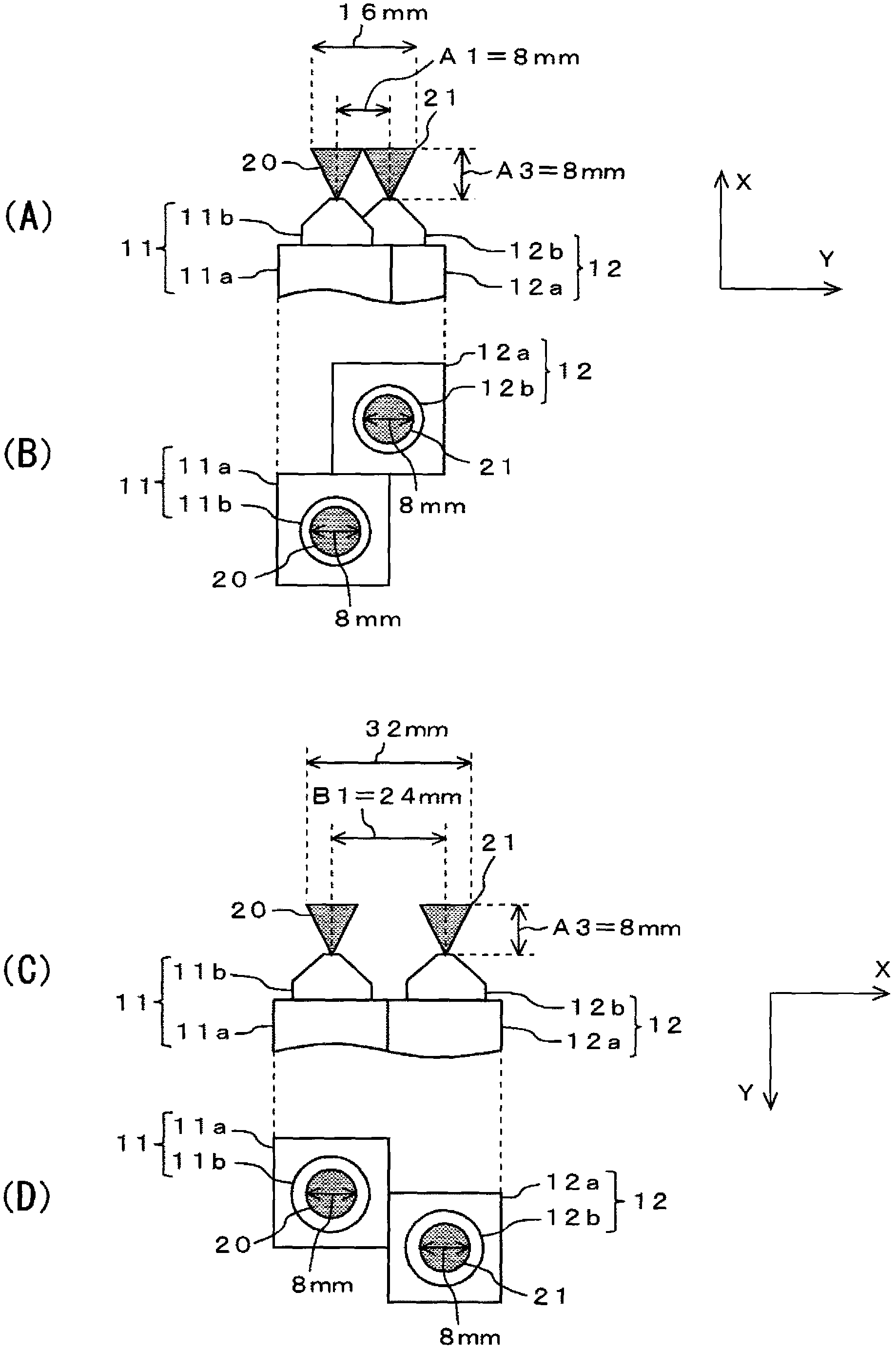

[0028] The plurality of nozzles of the jet flux applicator of the present invention are preferably provided at positions where the nozzles are shifted by a predetermined distance in a direction perpendicular to the movement direction of the nozzles. If the coating ranges overlap each other, when a plurality of nozzles spray flux at the same time, the flux collides with each other and scatters, so the flux may adhere to unnecessary parts.

[0029] In the spray flux applicator of the present invention, the spray openings of a plurality of nozzles are provided at positions shifted by a predetermined distance in a direction orthogonal to the moving direction, so that the plurality of nozzles can be placed close to the printed circuit board for application, and can be installed Sufficient flux is supplied to the entire through hole in the printed circuit board, and the wettability of the through hole can be improved. This can prevent soldering defects such as poor bridging and poor bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com