Synchronous printing and embossing machine

A technology of synchronous printing and embossing machine, applied in printing machine, rotary printing machine, printing and other directions, can solve the problems of insignificant embossing effect, single surface effect, high maintenance cost, and achieve compact structure and prominent pattern effect. , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific examples.

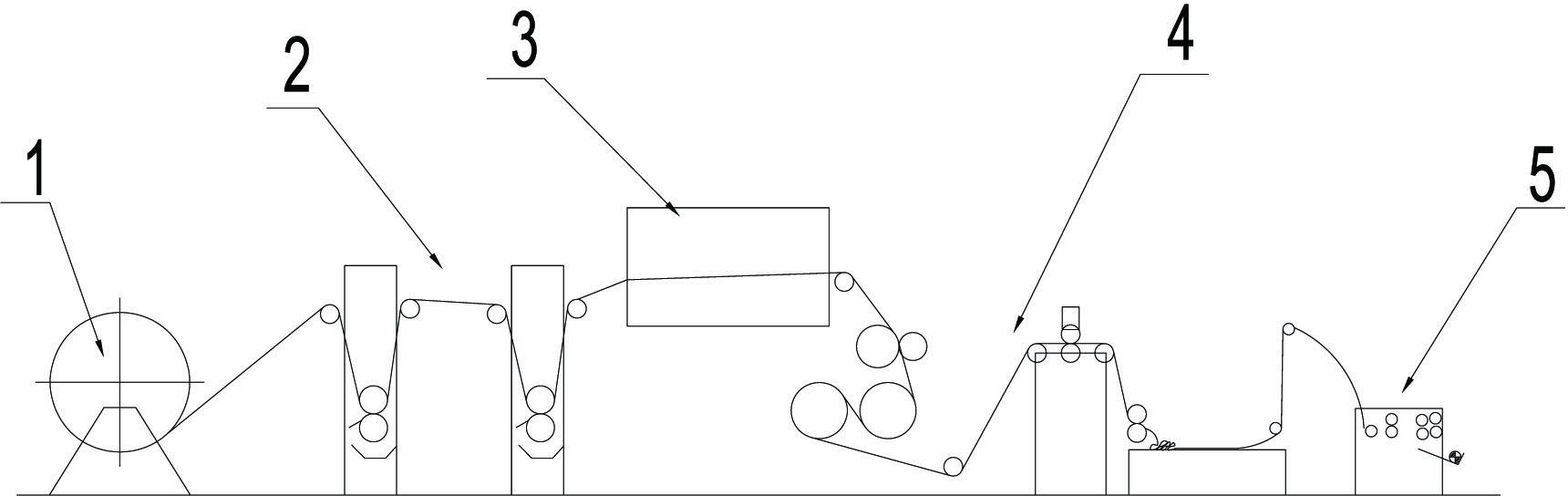

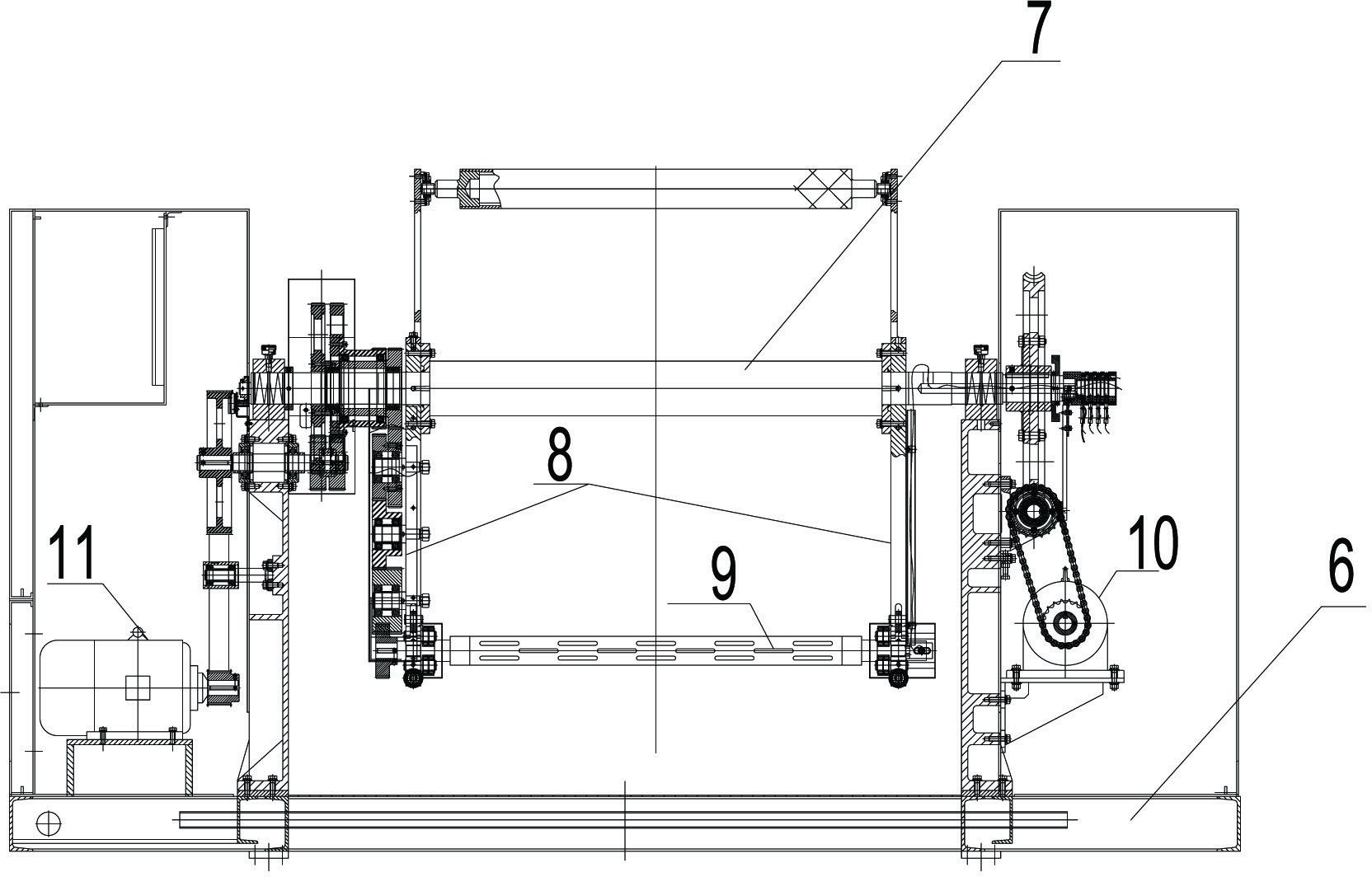

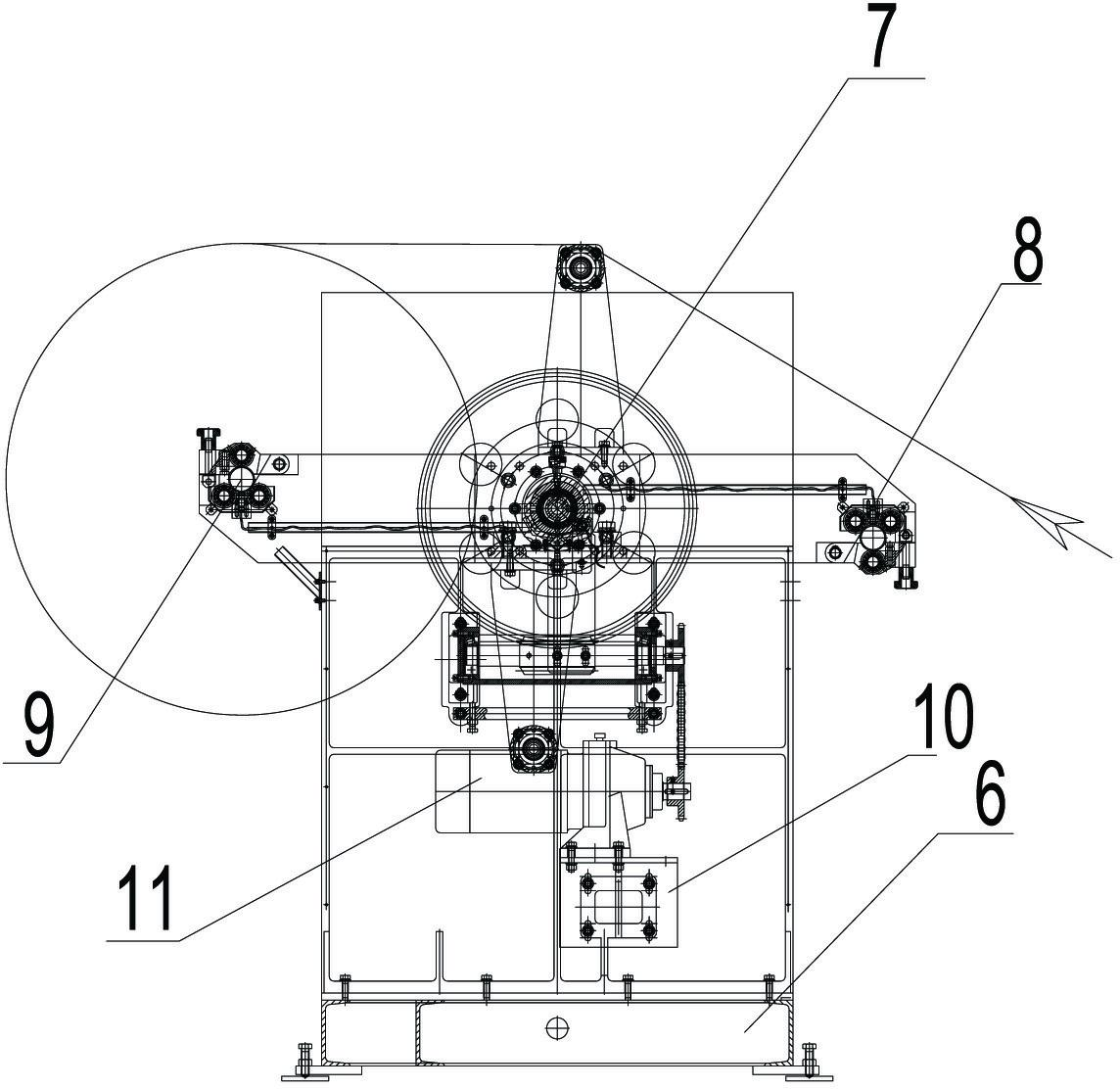

[0020] According to attached figure 1 to attach Figure 8 As shown, the synchronous printing and embossing machine described in this embodiment includes a double-station central unwinding mechanism 1, a printing group mechanism 2, a heating oven 3, a synchronous embossing mechanism 4, and a coreless winding mechanism 5. Wherein, the double-station central unwinding mechanism 1, the printing group mechanism 2, the heating oven 3, the synchronous embossing mechanism 4, and the coreless winding mechanism 5 are closely arranged in sequence along the unwinding direction, and the Works in tandem with synchronization.

[0021] The described double-station central unwinding mechanism 1 includes a frame 6, a rotating main shaft 7 mounted on the frame 6, a swing arm frame 8 assembled on the rotating shaft 7, and a swing arm frame 8 mounted on the swing arm frame 8. The air expansion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com