Start-up activating method of hydrocracking process

A technology of hydrocracking and start-up activation, applied in hydrotreating process, petroleum industry, treatment of hydrocarbon oil, etc., can solve the problem that the activation process is not further optimized, and achieve fully and thoroughly wetting, reduce cracking loss, and improve activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

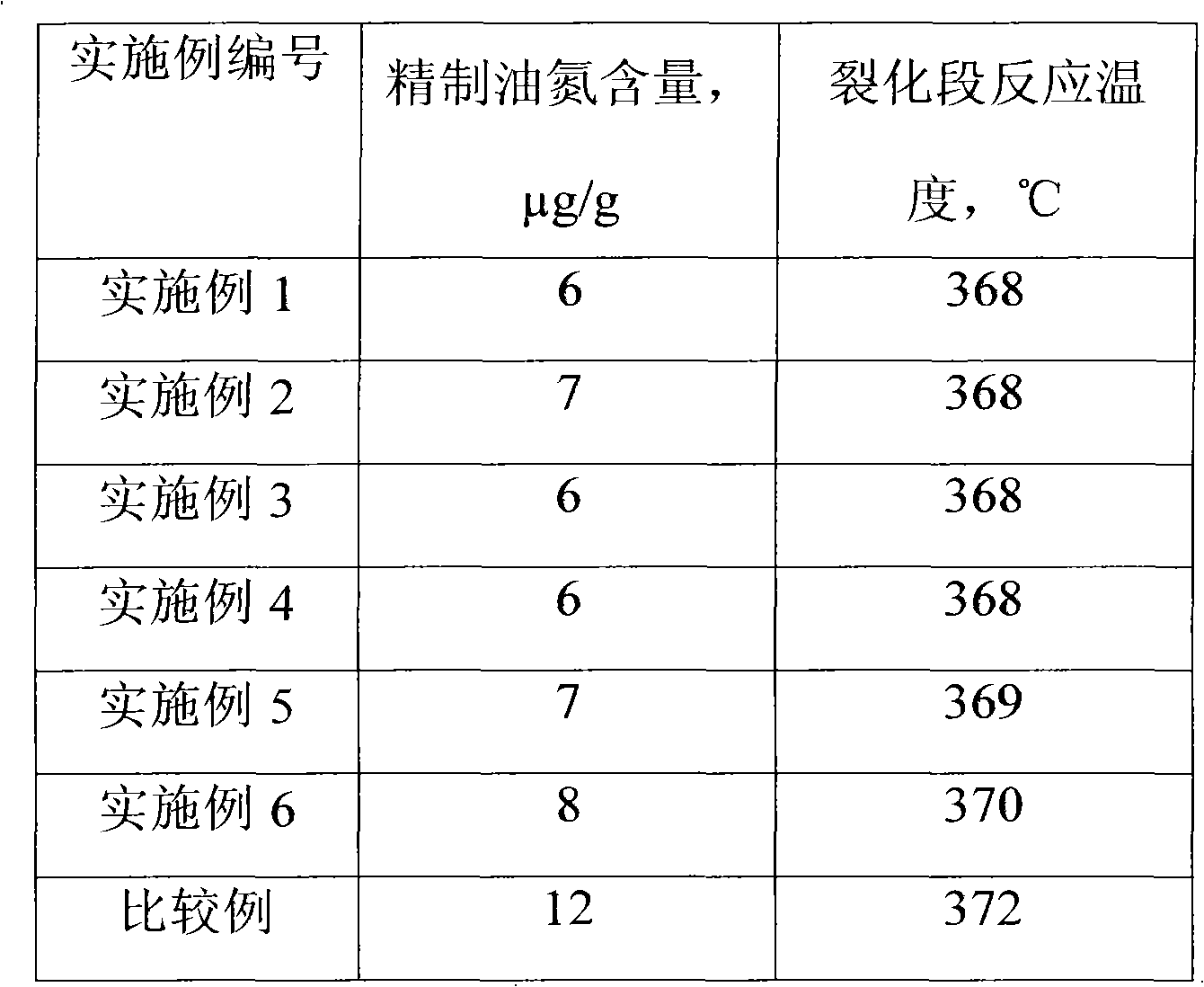

Embodiment 1

[0047] EPFF-46 and EPFC-32 are installed in their respective reactors and are airtight. After the airtightness is qualified, the hydrogen partial pressure is adjusted to 14.0MPa, the temperature is adjusted to 100°C, and the activation oil is introduced, and the volume space velocity of the activation oil is 2h -1 , the volume ratio of hydrogen to oil is 1000. Start to heat up to 220°C at 10°C / h, and start to withdraw the activated oil. Use hydrogen to continue to raise the temperature to 370°C at 10°C / h, keep the temperature constant for 8 hours, and when the constant temperature is over, switch the raw material oil according to the operation. After switching the feedstock, it was raised to 378°C and operated for 48 hours, and the oil samples were analyzed. The catalyst activity results are shown in Table 3.

Embodiment 2

[0049] EPFF-46 and EPFC-32 are installed in their respective reactors and are airtight. After the airtightness is qualified, the hydrogen partial pressure is adjusted to 14.0MPa, the temperature is adjusted to 150°C, and the activation oil is introduced, and the volume space velocity of the activation oil is 2h -1 , the volume ratio of hydrogen to oil is 1000. Start to heat up to 230°C at a rate of 10°C / h, and start to withdraw the activated oil. Use hydrogen to continue to raise the temperature to 370°C at 10°C / h, keep the temperature constant for 6 hours, and when the constant temperature is over, switch the raw material oil according to the operation. After switching the feedstock, it was raised to 378°C and operated for 48 hours, and the oil samples were analyzed. The catalyst activity results are shown in Table 3.

Embodiment 3

[0051] EPFF-46 and EPFC-32 are installed in their respective reactors and are airtight. After the airtightness is qualified, the hydrogen partial pressure is adjusted to 14.0MPa, the temperature is adjusted to 120°C, and the activation oil is introduced, and the volume space velocity of the activation oil is 2h -1 , the volume ratio of hydrogen to oil is 1000. Start to heat up to 220°C at 10°C / h, and start to withdraw the activated oil. Use hydrogen to continue to raise the temperature to 360°C at 10°C / h, keep the temperature constant for 8 hours, and when the constant temperature is over, switch the raw material oil according to the operation. After switching the feedstock, it was raised to 378°C and operated for 48 hours, and the oil samples were analyzed. The catalyst activity results are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com