Elastomer-metal bearing

An elastomer, metal technology, used in springs, springs/shock absorbers, springs made of plastic materials, etc., can solve the problems of large pin diameter, increased diameter of elastomer metal bearings, etc., to achieve the effect of compact shape design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

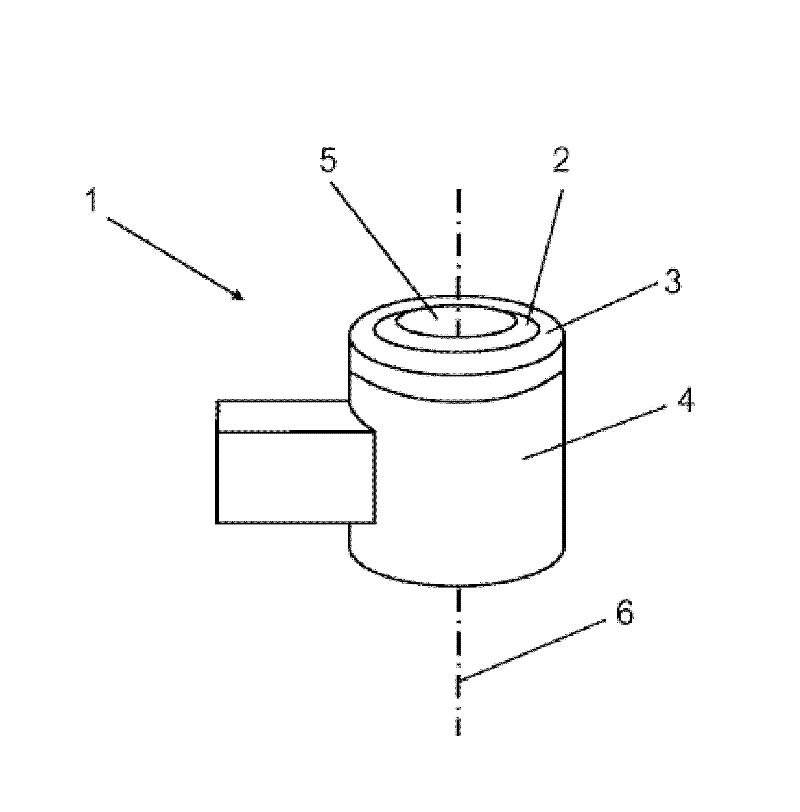

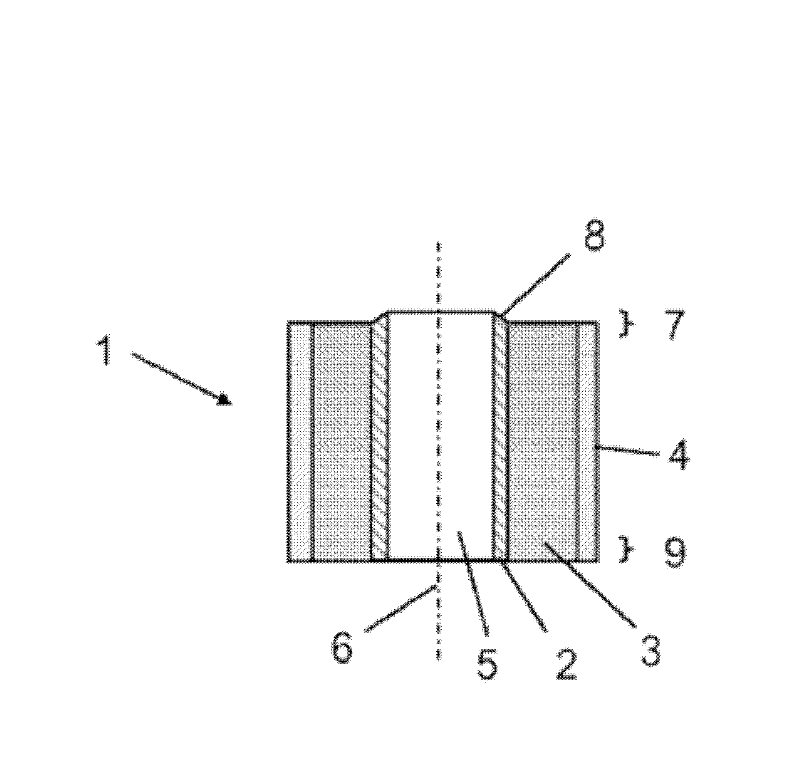

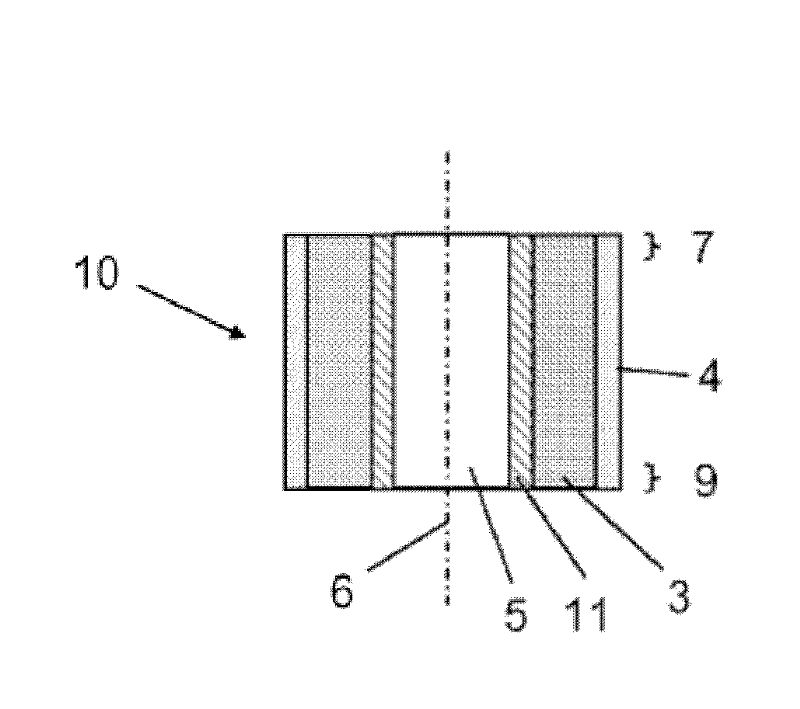

[0019] figure 1 A perspective view of an exemplary embodiment of an elastomeric metal bearing 1 according to the invention is shown. The elastomeric metal bearing 1 comprises a substantially rigid inner part 2, an elastomeric sleeve 3 (see figure 2 ) and a substantially rigid outer part 4 . An elastomer sleeve 3 is arranged between the inner part 2 and the outer part 4 . In particular in this exemplary embodiment, the inner part 2 is implemented as a metal sleeve or a cylindrical metal ring with holes 5 . This hole 5 is used to receive figure 1 Pins or bolts, not shown in , by means of which abutment parts or support parts, also not shown, can be connected to the inner part 2 of the elastomeric metal bearing 1 .

[0020] In its vertical range, figure 1 The inner part 2 in also defines the bearing axis or longitudinal axis 6 of the elastomeric metal bearing 1 . if available from figure 1 As seen in , the outer part 4 of the elastomeric metal bearing 1 is connected, eg w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com