Photovoltaic module mounting frame for middle and low latitudes

A photovoltaic module, low-latitude technology, applied in the direction of photovoltaic power generation, photovoltaic modules, photovoltaic module support structure, etc. problem, to achieve the effect of strong plasticity, good force effect, and excellent force effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

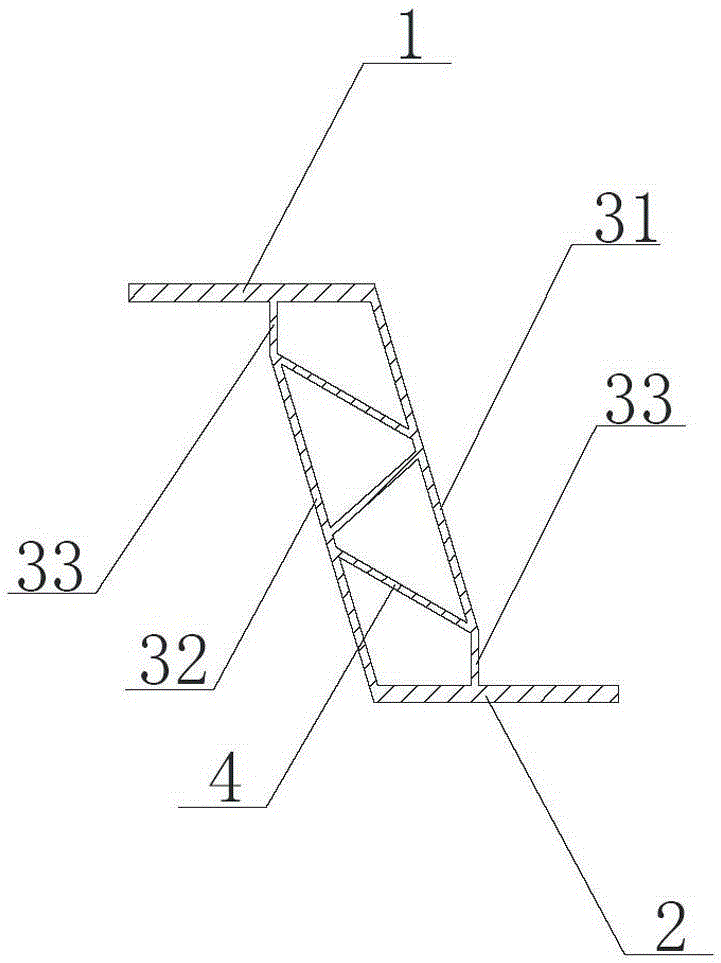

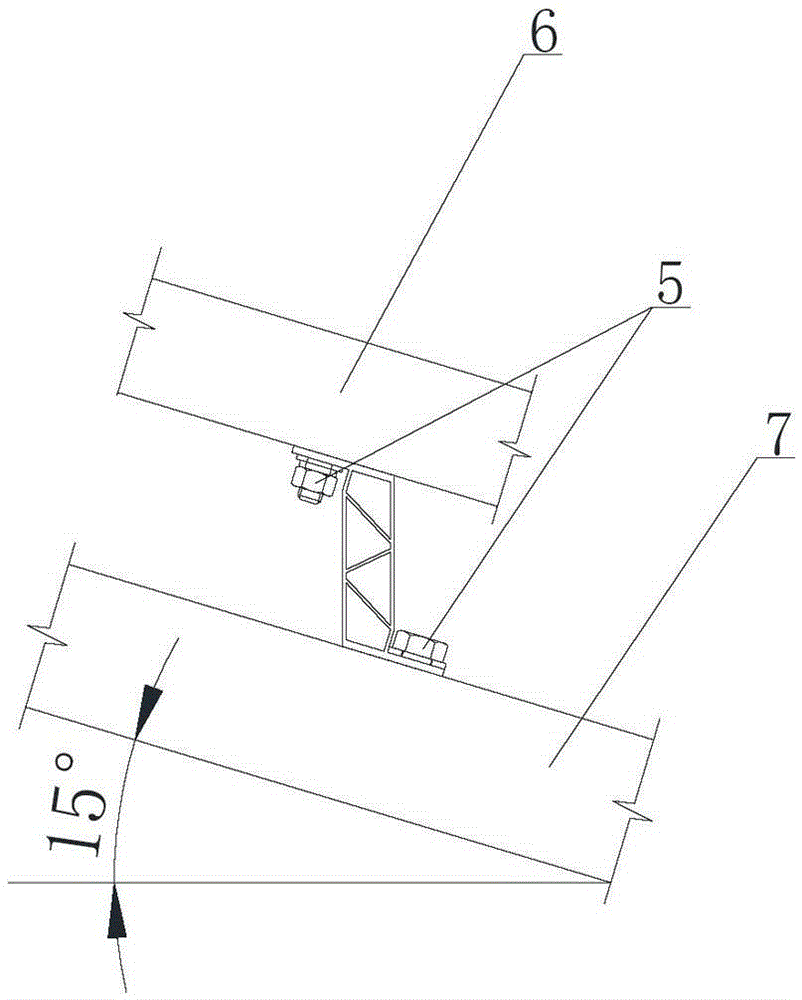

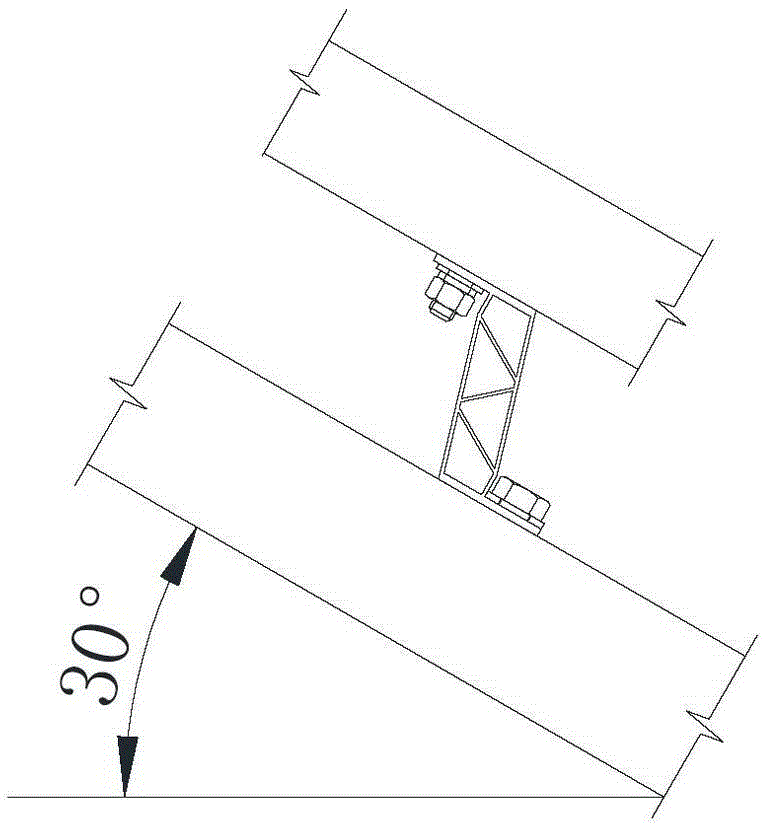

[0026] This embodiment is the most preferred for implementing the utility model. Such as figure 1 As shown, the photovoltaic module mounting frame for middle and low latitudes in this embodiment includes: an upper installation surface 1 and a lower installation surface 2, which are arranged parallel to each other; first main ribs 31 and second main ribs 32, which are arranged in parallel on Between the upper installation surface 1 and the lower installation surface 2, and form a Z-shaped structure with the upper installation surface 1 and the lower installation surface 2, the first main rib 31 and the second main rib 32 are also connected to the upper installation surface 1 and the lower installation surface respectively. 2 forms an included angle, the first main rib 31 forms an included angle of 105° with the upper mounting surface 1, and the second main rib 32 forms an included angle of 105° with the lower mounting surface 2; the three oblique ribs 4 are arranged obliquely i...

Embodiment 2

[0033] Others are the same as those described in Example 1, except that three main reinforcements are used, and multiple oblique reinforcements are arranged obliquely between every two main reinforcements, which can provide a stronger force bearing effect and are suitable for larger For the support of large-area photovoltaic modules, we can choose according to our own needs.

Embodiment 3

[0035] Others are the same as those described in Embodiment 1, except that: both ends of the main reinforcement can be provided with bending parts, which can make room for more components to be installed conveniently.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com