Planetary gear speed reducer

A planetary gear deceleration, external gear technology, applied in the direction of gear transmission, belt/chain/gear, engine, etc., can solve the problems of reduced transmission torque efficiency, rotation fluctuation, etc., to reduce bending stress, reduce loss, high efficiency The effect of torque transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

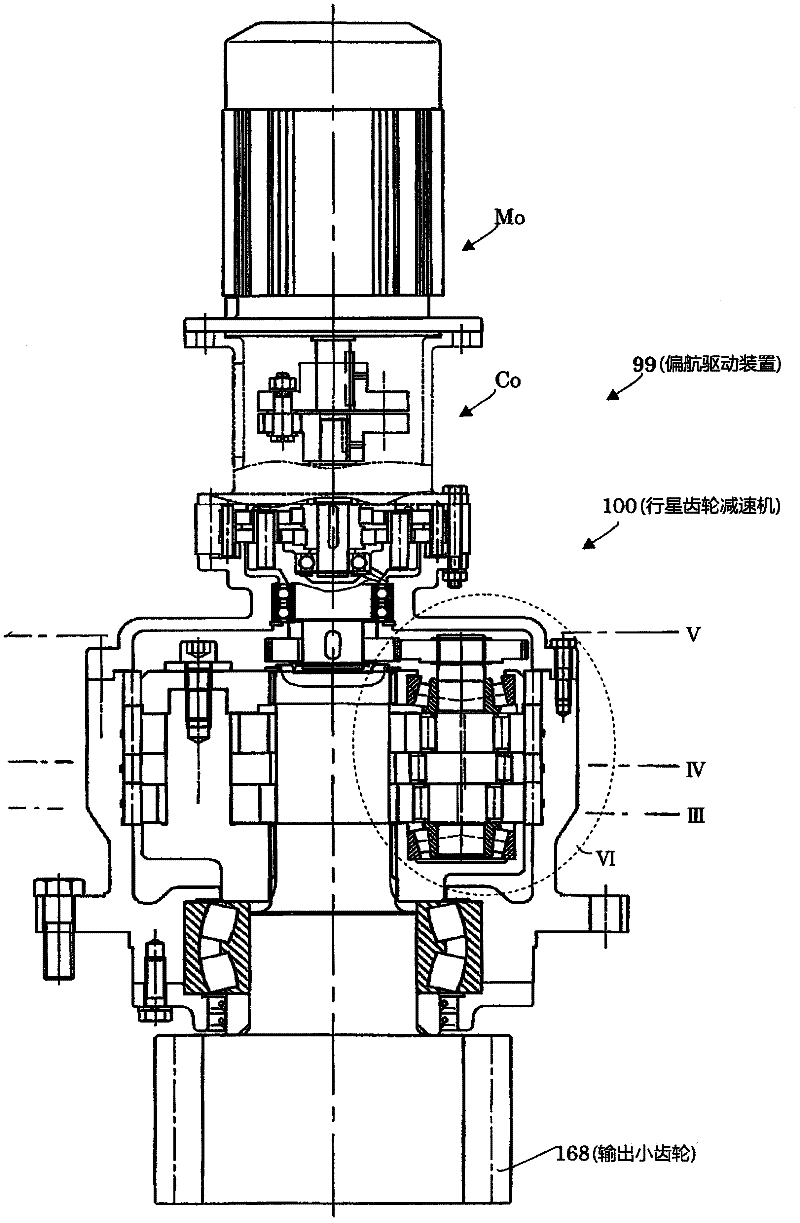

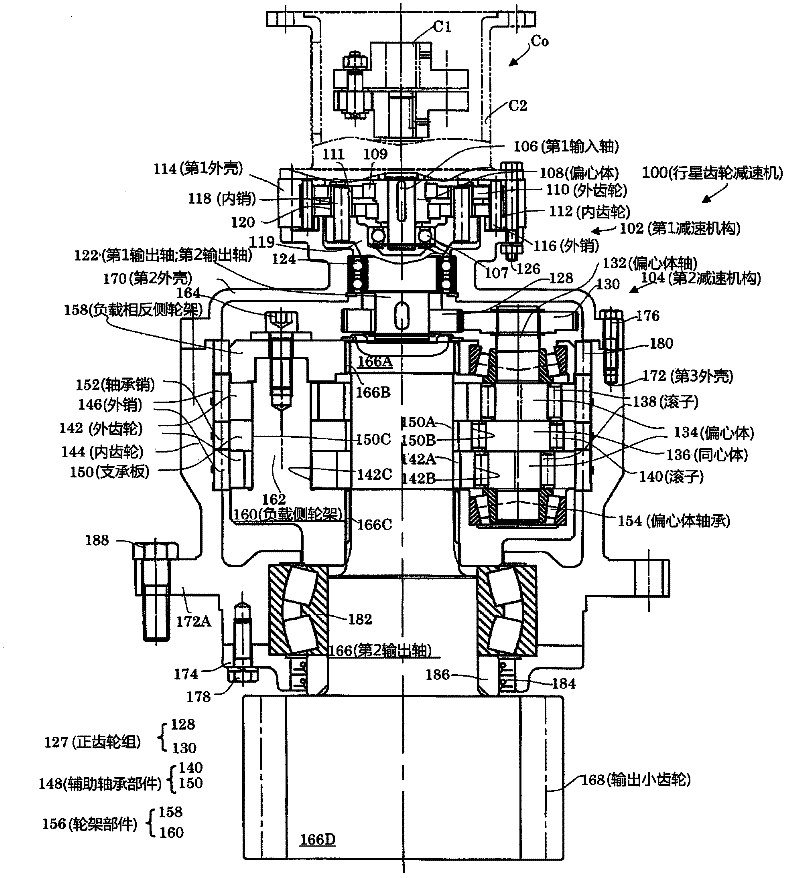

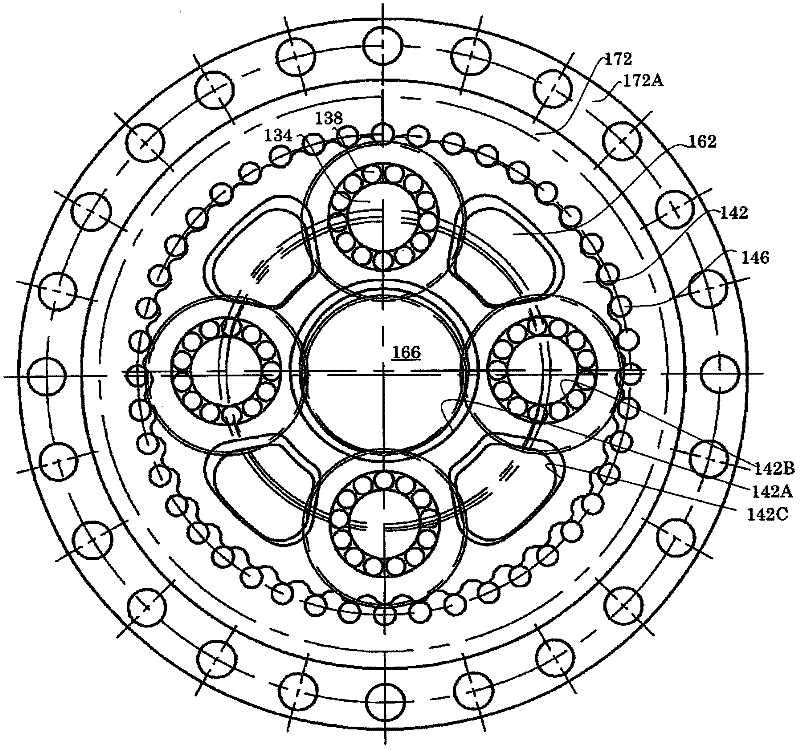

[0032] Hereinafter, an example in which the planetary gear reducer according to the first embodiment of the present invention is applied to a yaw drive device of a wind power generator will be described with reference to the drawings.

[0033] First, use Figure 10 ~ Figure 12 A description will be given from the outline of a wind power generator incorporating this planetary gear reducer.

[0034] Such as Figure 10 As shown, this wind power generator 10 is equipped with a power generation unit 12 at the uppermost part of a cylindrical column 11 . A yaw (Yaw) driving device 99 and a pitch (Pitch) driving device 98 are assembled on the power generating unit 12 . The yaw driving device 99 is a device for controlling the rotation angle of the power generating unit 12 as a whole relative to the cylindrical pillar 11, and the pitch driving device 98 is a device for controlling the pitch angle of the three windmill blades installed on the nose cone 18 .

[0035] In this embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com