Solar heat utilization thermostatical control system based on flow control

A constant temperature control, solar thermal technology, applied in solar heating system, solar thermal energy, solar thermal power generation and other directions, can solve the problems of high finished product price of electric regulating valve, thermal protection of motor, easy damage of reduction gear, etc., to achieve significant energy saving benefits and Economic efficiency, high constant temperature accuracy, low intelligent control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

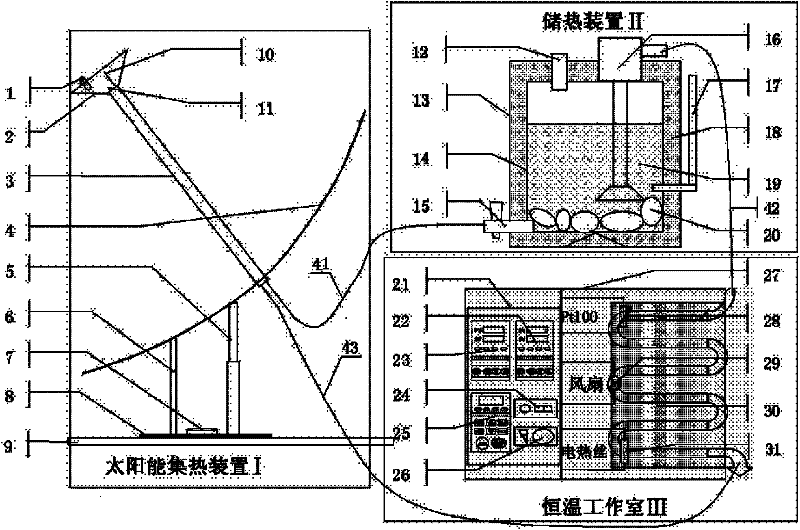

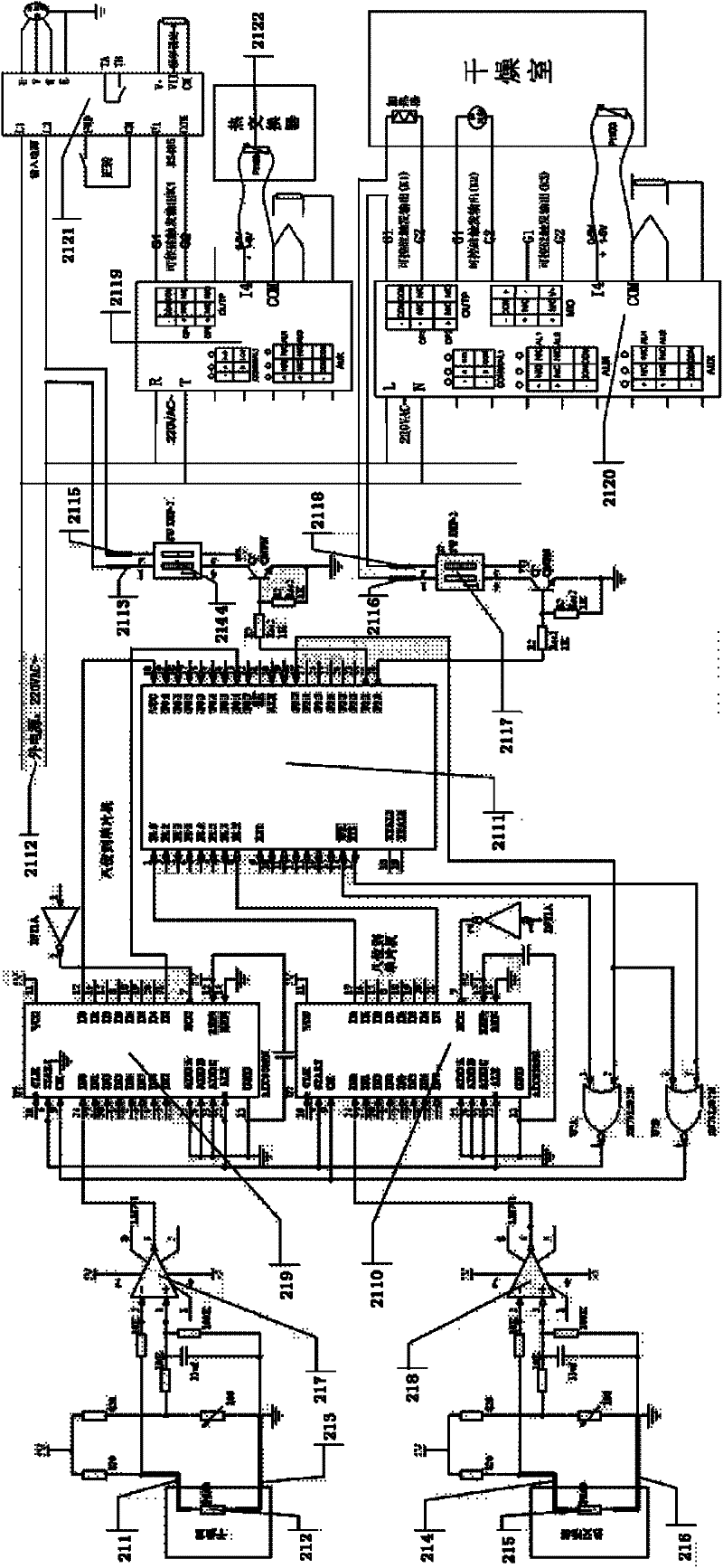

[0066] according to figure 1 It can be seen that the present invention includes solar heat collecting device I, heat storage device II, constant temperature studio III, three separate devices, plus a constant temperature control device IV integrated on the constant temperature studio III, consisting of four functional parts.

[0067] figure 1 Shown is a schematic diagram of the structure of the solar electric energy constant temperature control device. Including solar heat collection device I, heat storage device II, constant temperature studio III. Solar heat collection device I includes: mechanical valve 1, conical boiler 2, support pipe 3, plane group concentrating paraboloid 4, hydraulic cylinder 5, fixed pole 6, rotating bearing 7, rotating round table 8, flat support 9, heat transfer oil Output copper pipe 10, heat conduction oil input copper pipe 11. The mechanical valve 1 is installed on the upper surface of the cone boiler 2 to ensure the internal pressure of the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com