Sensor control method and control device thereof

A control method and sensor technology, applied in the direction of instruments, signal transmission systems, electrical signal transmission systems, etc., can solve the problems of affecting the accuracy, the sensor is in working state, and the working life is short, and achieve the effect of prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

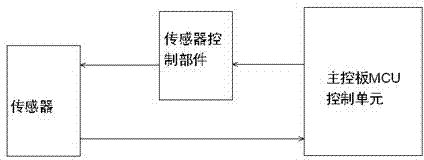

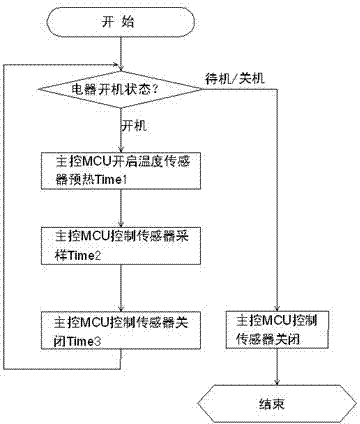

[0035] Embodiment 1 Temperature sensor control circuit.

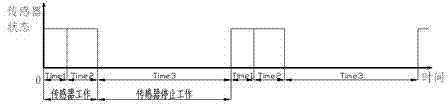

[0036] Figure 4 For ordinary temperature sampling circuit; Figure 5 In order to increase the temperature sampling circuit of the control part.

[0037] Figure 4 Among them, the main control MCU is the control core of household appliances. In this example, NEC0511 single-chip microcontroller is used. The reset circuit and crystal oscillator circuit are on the left side of NEC0511, and the temperature sampling circuit is on the top, and other peripheral circuits are omitted. The temperature sensor is a thermistor, the resistance value changes with temperature, and R18 is a voltage divider 8.1K resistor. When the temperature changes, the output resistance of the temperature sensor will change, and the voltage at both ends of the sensor will change, that is, the voltage at point A will change. The control MCU performs AD conversion to collect voltage through pin34, and calculates the temperature according to the coll...

Embodiment 2

[0044] Embodiment 2 Carbon dioxide sensor control circuit.

[0045] Figure 6 For ordinary carbon dioxide sampling circuit, Figure 7 For adding control components to the carbon dioxide sampling circuit compared to Figure 6 .

[0046] Figure 6 Among them, the main control MCU is the control core of household appliances. In this example, NEC0511 single-chip microcontroller is used. The reset circuit and crystal oscillator circuit are on the left side of NEC0511, and the carbon dioxide detection and sampling circuit is on the top, and other peripheral circuits are omitted. The carbon dioxide sensor is an electrochemical sensor that outputs 0-4.5V voltage according to the change of carbon dioxide concentration. When the carbon dioxide concentration changes, the sensor output voltage (Output port) changes accordingly. After being filtered by capacitors E19, R142, and C75, it is connected to the pin34 port of the main control MCU. The main control MCU performs AD conversion t...

Embodiment 3

[0053] Embodiment 3 Humidity sensor control circuit.

[0054] Figure 8 It is an ordinary humidity sampling circuit.

[0055] Figure 8 Among them, the main control MCU is the control core of household appliances. In this example, NEC0511 single-chip microcontroller is used. The left side of NEC0511 is the reset circuit and crystal oscillator circuit. The upper part is the humidity detection sampling circuit, and other peripheral circuits are omitted. The humidity sensor is a polymer humidity sensitive resistor, which outputs 1-3V voltage according to the change of humidity. When the humidity changes, the sensor output voltage (Output port) changes accordingly. After being filtered by capacitors E3, R15, and C1, it is connected to the pin34 port of the main control MCU. The main control MCU performs AD conversion through pin34 to collect the voltage, and according to the collected The voltage information calculates the humidity.

[0056] exist Figure 8 Among them, a Q600...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com