Control method and system for reducing the common-mode current in power converter

A power converter, common mode current technology, applied in the field of control and system for reducing the common mode current in the power converter, can solve the unsatisfactory, reduce the common mode voltage of the variable speed drive, can not etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

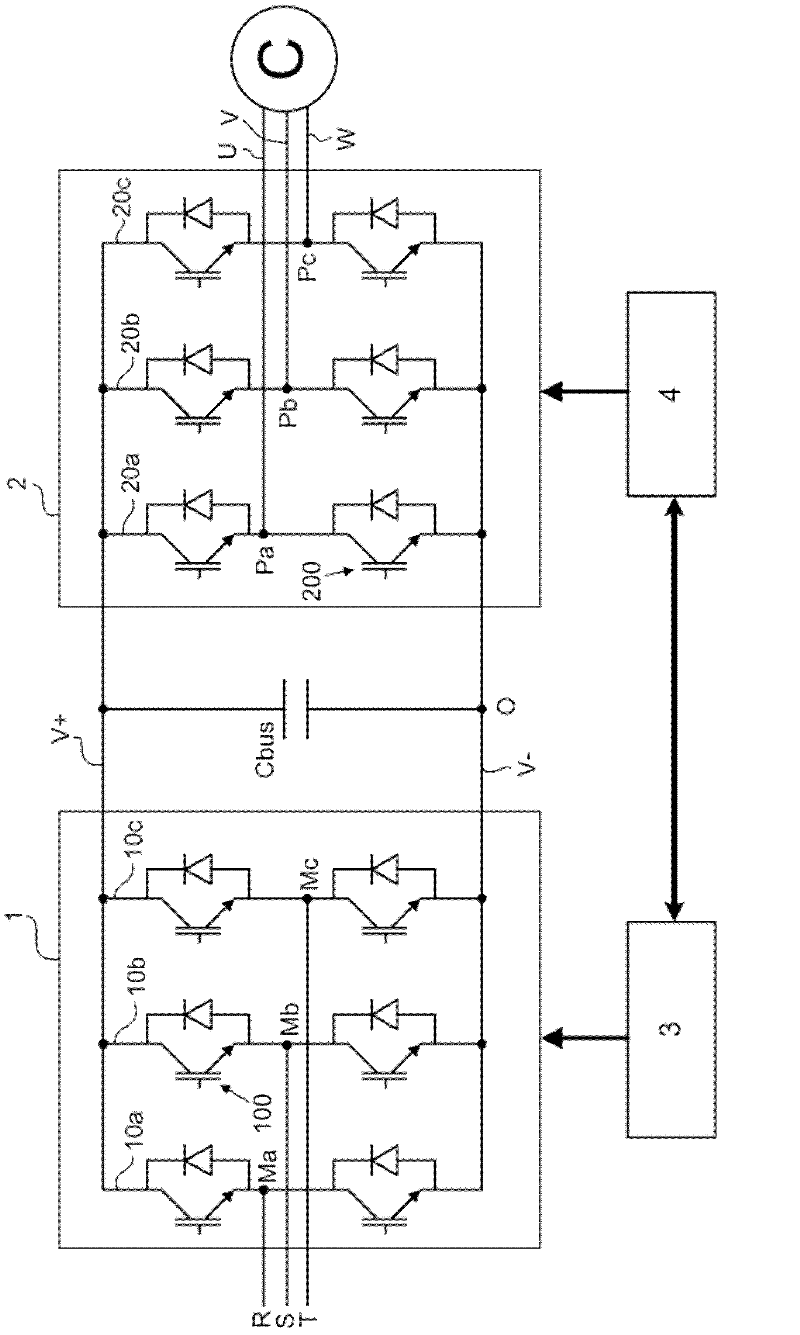

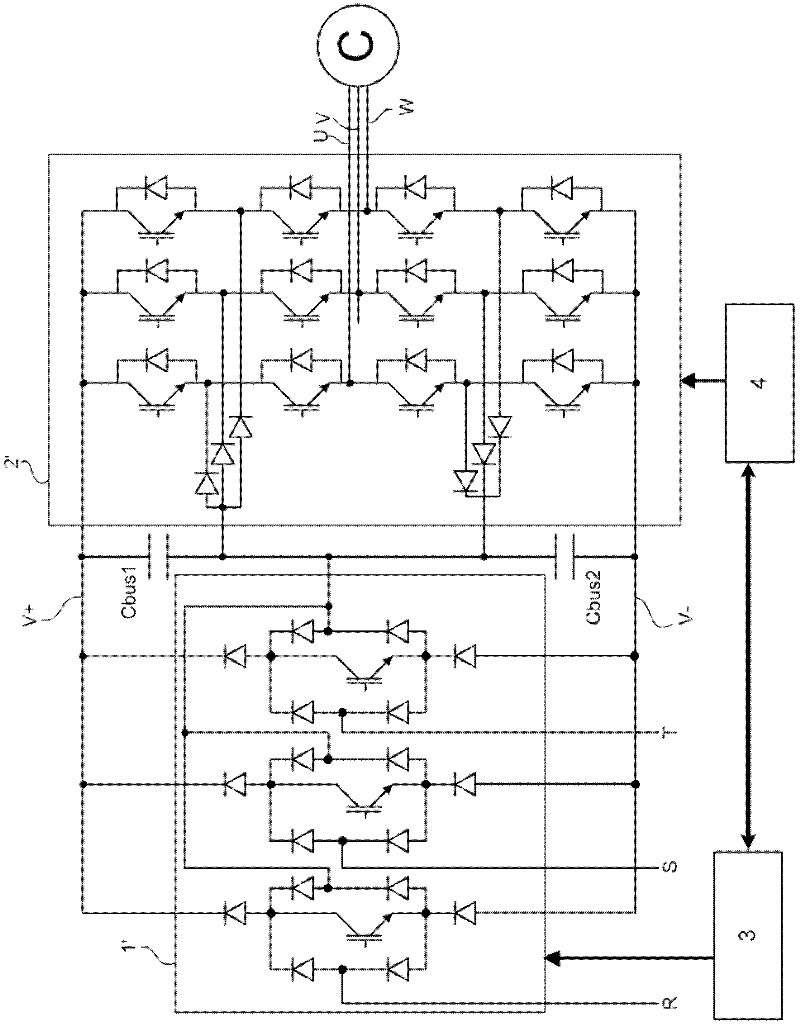

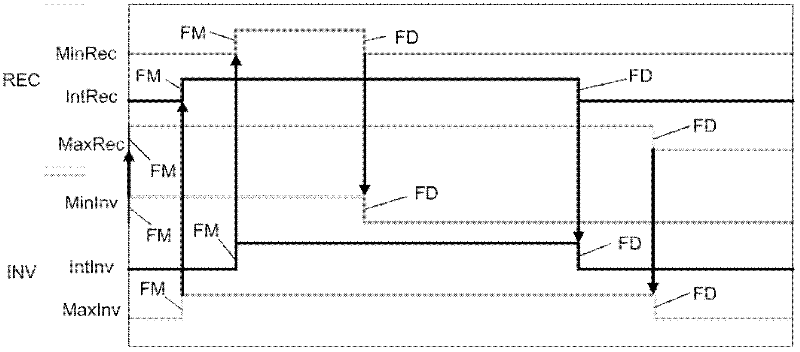

[0034] refer to figure 1 and 2 As is known, a power converter, for example of the variable speed drive type, comprises a rectifier stage 1, 1', a DC supply bus and an inverter stage 2, 2'. Different power converter configurations are possible. The invention finds most particular application in power converters comprising active rectifier stages.

[0035] figure 1 represents, for example, a two-level variable speed drive with active rectifier stage 1 . figure 2 A three-level variable speed drive is shown, for example employing an inverter stage 2' of NPC (Neutral Point Clamped) type and an active rectifier stage 1' of Vickers bridge type. Other configurations are also possible, such as using an inverter stage with flyback capacitors.

[0036] refer to figure 1 , the rectifier stage 1 is connected to the mains supply via AC inductors (not shown), eg on the three input phases R, S, T for the three-phase rectifier stage 1 . Typically, in variable speed drives, the rectifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com