Attachment system for ratchet type wrenches

A ratcheting, wrench technique used in the mechanism of bolts and other fasteners to remove and install nuts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

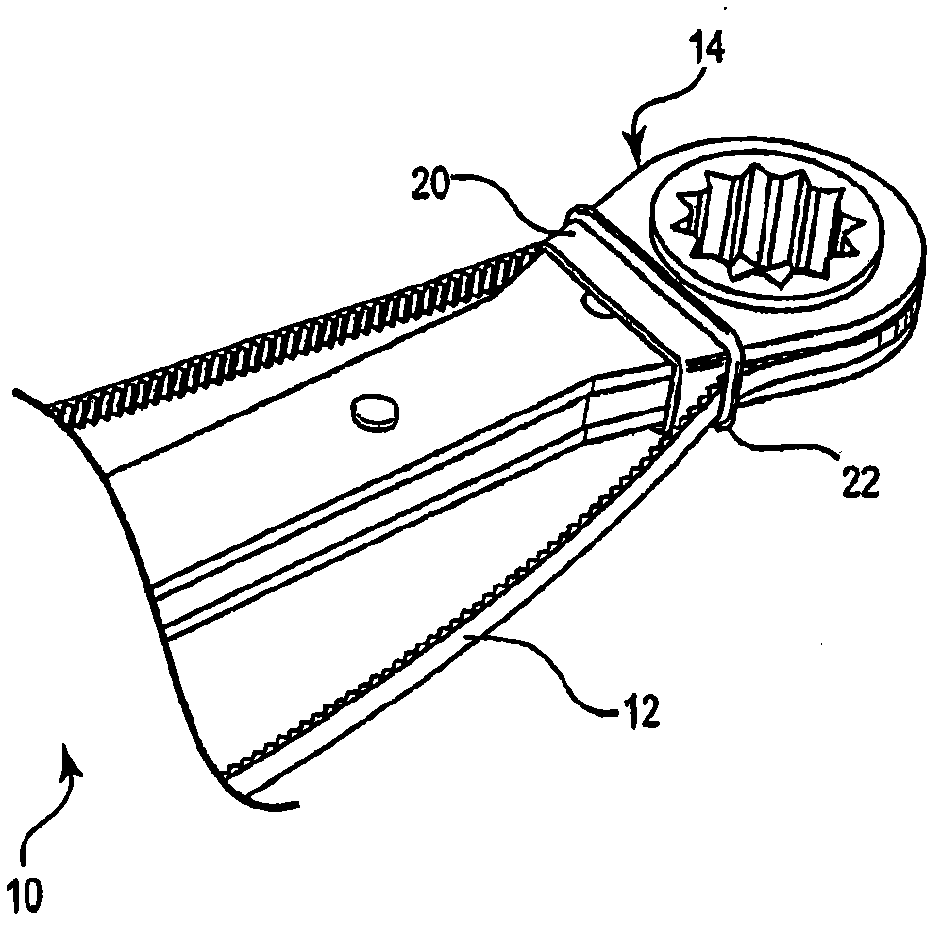

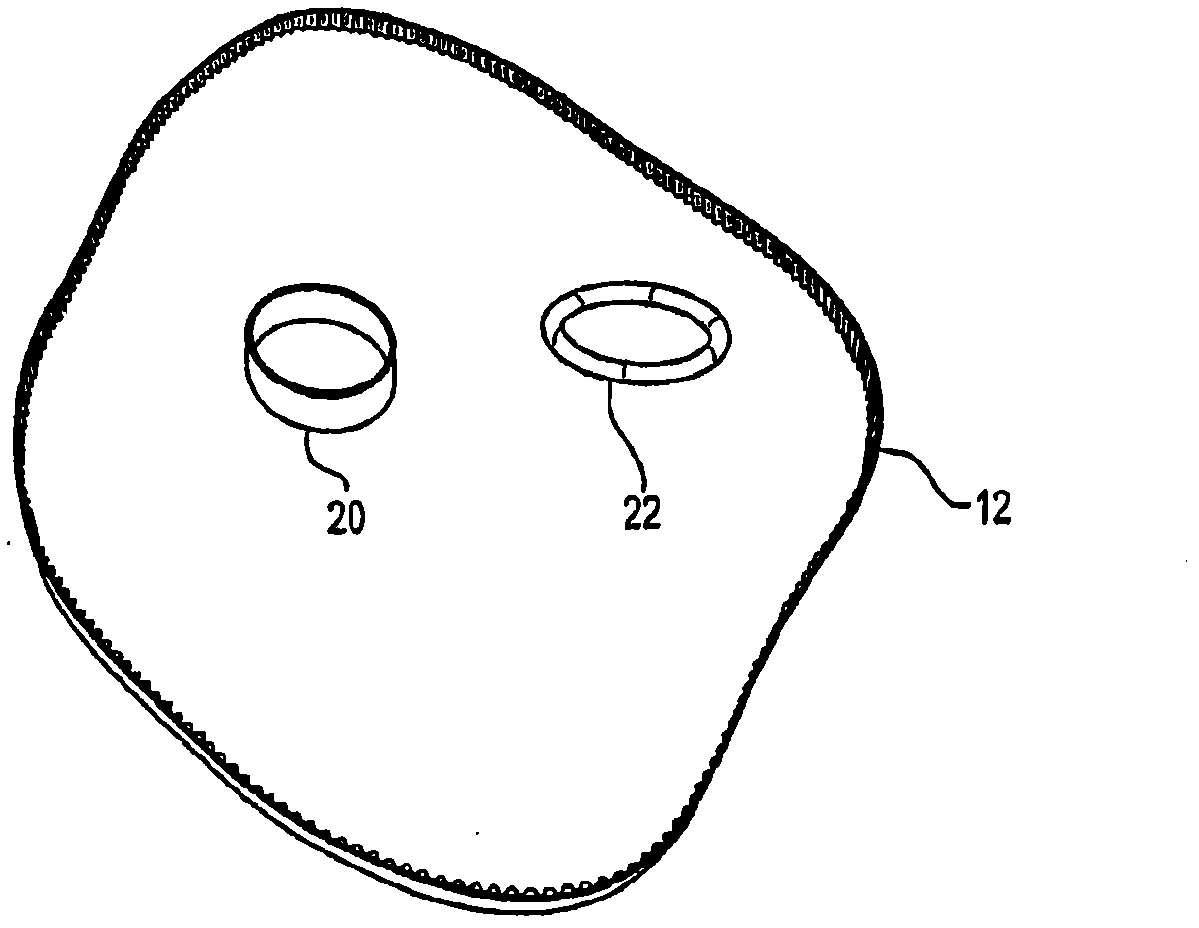

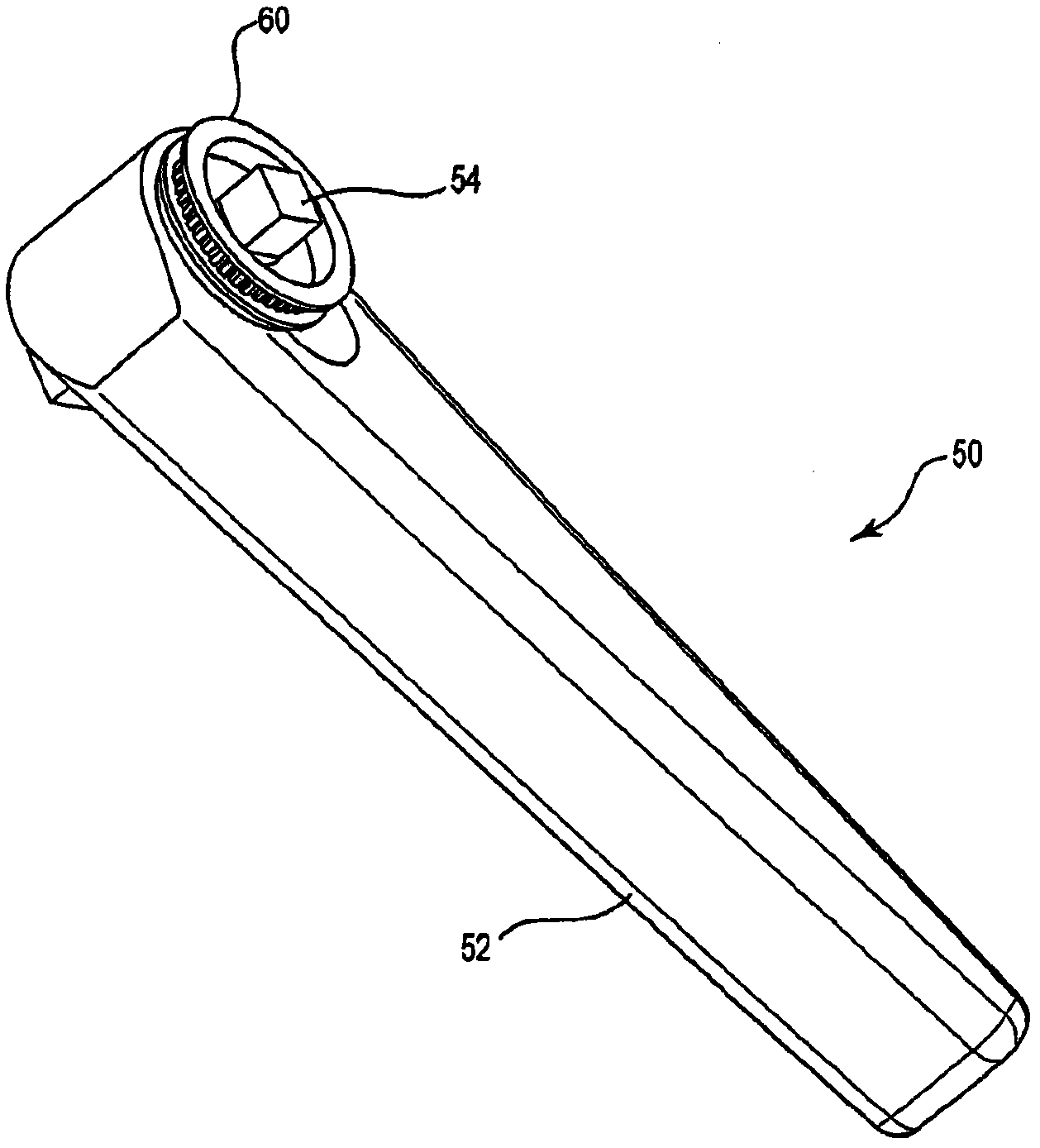

[0025] Generally speaking, one aspect of the present invention involves the use of a belt specifically designed to engage a drive mechanism, thereby converting a standard ratchet wrench into a high speed tool. This aspect generally requires that the strap have some engagement formations thereon that mate or engage with similar engagement formations in the wrench. However, as discussed further below, this engagement does not necessarily require close engagement of the components (ie, the teeth of the belt do not necessarily have to mate with the teeth of the drive structure). In addition to the strap, some retaining structure is required to maintain a certain level of engagement at the drive end while allowing the free end of the strap to be accessible to the user. By combining these different aspects of the present invention, an efficient and effective tool is formed that provides high speed operation that cannot be provided by other devices.

[0026] As suggested above, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com