Complex-shaped gel-metal composite prosthesis and manufacturing method thereof

A metal composite and prosthetic technology, used in prostheses, bone implants, medical science, etc., can solve the problems of difficulty in making impressions, reduced patient openings, complicated clinical adjustment work, etc., and achieve supporting strength. Long-term non-deformation, repair of soft and hard tissue defects, and good retention and stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

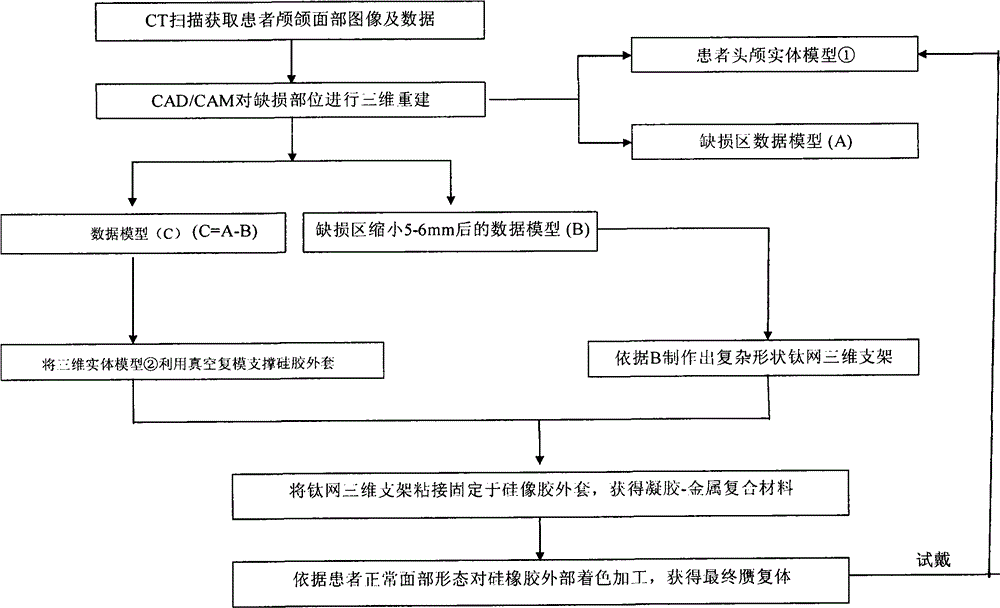

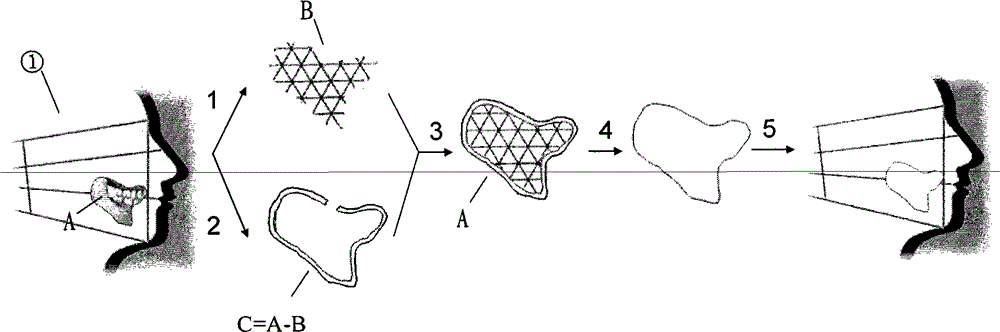

[0027] The preparation gel-metal composite prosthesis processing technological process provided by the present invention, such as figure 1 As shown, it specifically includes the following steps: 1) acquiring the image data of the patient's craniomaxillofacial region and defect (right cheek);

[0028]Wherein, the acquisition method is a CT scanning method. In order to make the gel-metal composite prosthesis obtained in step 5) suitable for the patient's craniomaxillofacial region and defect (right cheek), the image data obtained in this step was also used to prepare a three-dimensional solid model of the patient's craniomaxillofacial region①, specifically The steps are: use a rapid prototyping machine (purchased from Shanghai Fuqifan Electromechanical Technology Co., Ltd. model HTS-300 rapid prototyping machine), adopt the melting extrusion molding method provided in the manual of the rapid prototyping machine, and obtain the patient's craniomaxillofacial The three-dimensional...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com