Motor-driven hydraulic lifting machine for mounting urban rail vehicle tractor body

A technology for urban rail vehicles and elevators, applied in the direction of hoisting devices, etc., can solve the problems of labor, danger, side jumping, etc., and achieve the effects of saving man-hours and costs, safe and reliable operation, and flexible and convenient movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

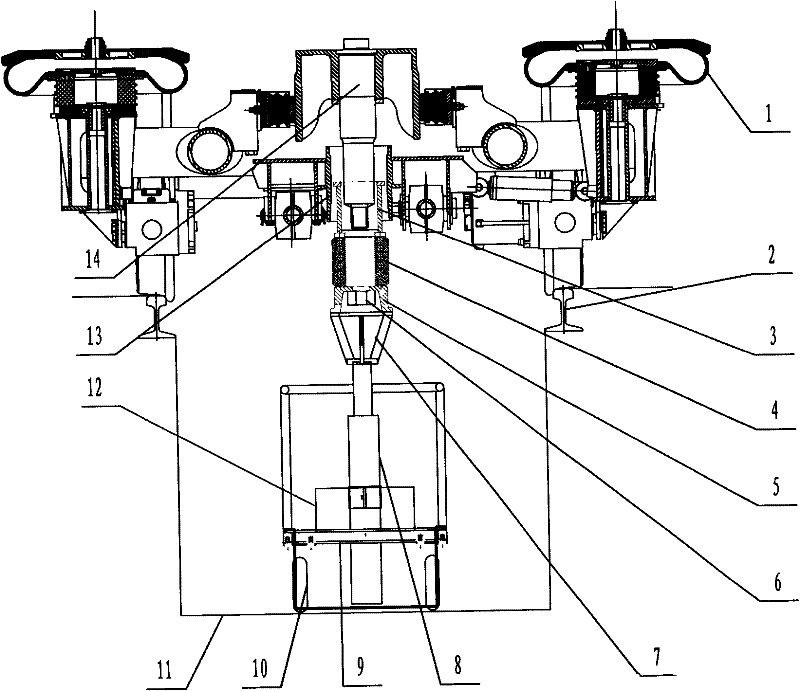

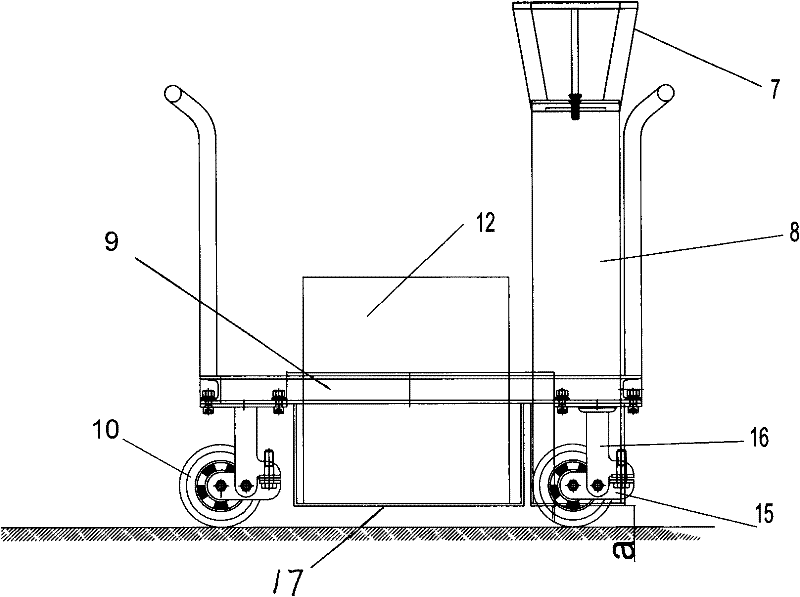

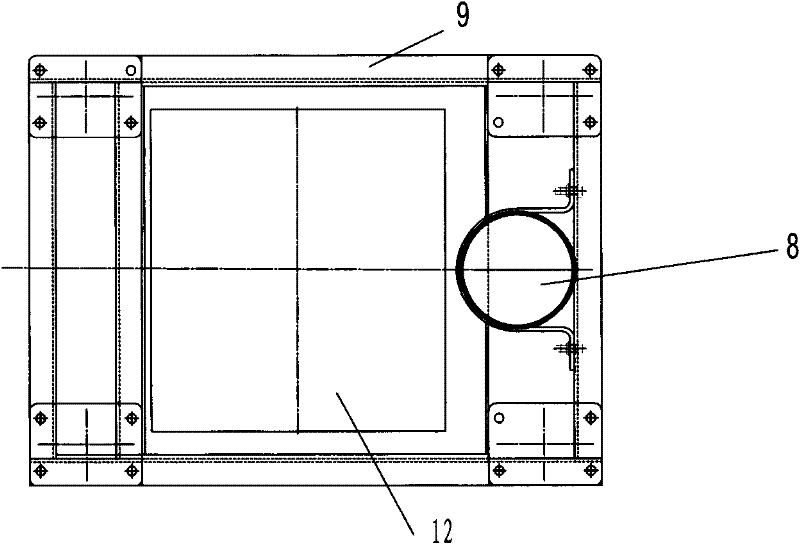

[0018] Now in conjunction with accompanying drawing, the present invention will be further described: with reference to figure 1 , the bogie 1 sits on the track 2 through the wheel, the spacer composition 3, the composite spring 4, and the gland 5 are set on the center pin 14 and pressed into the center tube 13 of the bogie, and the traction body locks the nut 6 Tighten the lower end of the center pin 14 to complete the connection between the car body and the bogie. In order to assemble spacer components 3, composite springs 4, gland 5, and locking nut 6 of the traction body, an electro-hydraulic lift is designed, which includes a hydraulic cylinder 8 and an electro-hydraulic pump 12, and the hydraulic cylinder 8 and the electro-hydraulic pump 12 are seated On the vehicle frame 9, four damping wheels 10 are arranged at the bottom of the vehicle frame. The damping wheels 10 are purchased parts. The model of the damping wheels 10 is SA620PSRCC, which is produced by Universal Cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com