Method for preparing vat brilliant red RB

A technology of brilliant red and perylenetetraic acid dianhydride is applied in the field of preparation of reduced brilliant red RB, which can solve the problems of long reaction time, high production cost, and high toxicity of solvents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

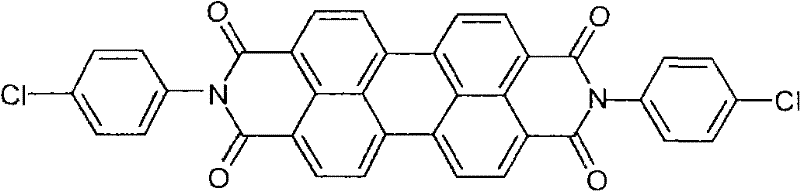

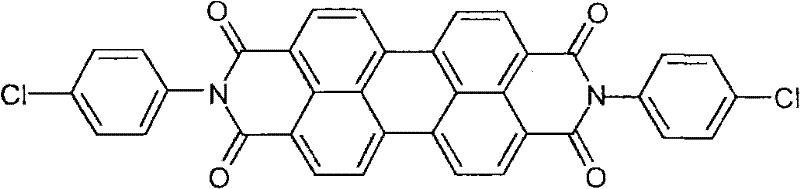

[0021] Preparation of Vat Red RB, namely N,N'-bis(p-chlorophenyl)-3,4,9,10-perylenetetracarboximide (C.I. Vat Red 32)

[0022] 62.6 g (0.16 mol) of 3,4,9,10-perylenetetraacid dianhydride was added to 1200 g of 6% by weight KOH aqueous solution, and the temperature was raised to 90° C. to completely dissolve it. Cool to 50°C, add dropwise 65g of 98% by weight H 2 SO 4 The solution was stirred evenly (PH=5-6), filtered and washed. The perylenetetracarboxylic acid filter cake was mixed with water, and the total amount was adjusted to 724g. Add 51.1g of p-chloroaniline (0.401mol) and 28.4g of pyridine (0.360mol), mix evenly, transfer the material to an autoclave, seal it, heat up to 145-150°C (0.3-0.4MPa), keep stirring for 4h, Sampling and testing, if the perylenetetraic dianhydride in the reactant is exhausted, the reaction is over, cooled to room temperature, and filtered. Wash with hot water until there is no green fluorescence, and obtain the crude product filter cake of ...

Embodiment 2

[0024] 62.6 g (0.16 mol) of 3,4,9,10-perylenetetraacid dianhydride was added to 1200 g of 6% by weight KOH solution, and the temperature was raised to 90° C. to completely dissolve it. Cool to 50°C, add dropwise 65g of 98% by weight H 2 SO 4 The solution was stirred evenly (PH=5-6), filtered and washed. The perylenetetracarboxylic acid filter cake was mixed with water, and the total amount was adjusted to 724g. Add 51.1g of p-chloroaniline (0.401mol) and 28.4g of pyridine (0.360mol), mix evenly, transfer the material to an autoclave, seal it, heat up to 135-140°C (0.2-0.3mPa), keep stirring for 4h, Sampling and testing, if the perylenetetraic dianhydride in the reactant is exhausted, the reaction is over, cooled to room temperature, and filtered. Wash with hot water until there is no green fluorescence, and obtain the crude product filter cake of reduced brilliant red RB. The filter cake is beaten with water, and 10% by weight of sodium hypochlorite solution is added to ad...

Embodiment 3

[0026] 62.6 g (0.16 mol) of 3,4,9,10-perylenetetraacid dianhydride was added to 1200 g of 6% by weight KOH solution, and the temperature was raised to 90° C. to completely dissolve it. Cool to 50°C, add dropwise 65g of 98% by weight H 2 SO 4 After the solution was stirred evenly (PH=5-6), it was filtered and washed. The perylenetetracarboxylic acid filter cake was mixed with water, and the total amount was adjusted to 724g. Add 81.3g of p-chloroaniline (0.638mol) and 28.4g of pyridine (0.360mol), mix evenly, transfer the material to an autoclave, seal it, heat up to 135-140°C (0.2-0.3MPa), keep stirring for 4h, Sampling and testing, if the perylenetetraic dianhydride in the reactant is exhausted, the reaction is over, cooled to room temperature, and filtered. Wash with hot water until there is no green fluorescence, and obtain the crude product filter cake of reduced brilliant red RB. The filter cake is beaten with water, and 10% by weight of sodium hypochlorite solution i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com