A kind of novel decorative leather based on ramie fiber powder and preparation method thereof

A technology of ramie fiber and decorative leather is applied in the field of new decorative leather based on ramie fiber powder and its preparation field, and can solve the problems of poor environmental protection performance, poor corrosion resistance, poor ventilation and moisture absorption of decorative leather, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

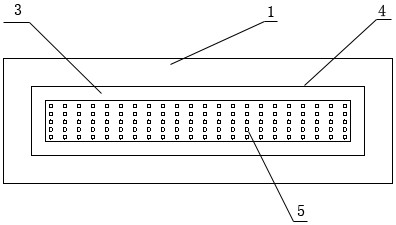

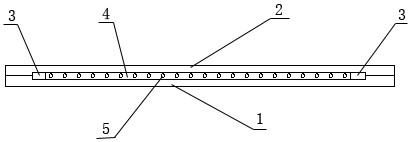

[0025] Such as figure 1 and 2 As shown, a new type of decorative leather based on ramie fiber powder, including upper fitting surface 2, lower fitting surface 1, anti-corrosion ring body 3, ramie fiber powder body 5; anti-corrosion ring body 3 can be polytetrafluoroethylene material Made; the components of the lower bonding surface 1 and parts by weight are as follows: 100 parts of PVC resin, 4 parts of stabilizer, 3 parts of foaming agent, 30 parts of calcium carbonate; each group of the upper bonding surface 2 The parts and parts by weight are as follows: 100 parts of PVC resin, 40 parts of plasticizer, 10 parts of color cake; the plasticizer is DOP dioctyl phthalate; the upper bonding surface 2 and the lower bonding surface 1 pass Hot pressing butt jointing; the upper butt joint groove is provided on the lower side of the upper joint surface 2; the lower butt joint groove is provided on the upper side of the lower joint surface 1; the upper butt joint groove and the lower ...

Embodiment 2

[0032] Such as figure 1 and 2 As shown, a new type of decorative leather based on ramie fiber powder, including upper fitting surface 2, lower fitting surface 1, anti-corrosion ring body 3, ramie fiber powder body 5; anti-corrosion ring body 3 can be polytetrafluoroethylene material Made; The components and parts by weight of the lower fitting surface 1 are as follows: 100 parts of PVC resin, 4.5 parts of stabilizer, 3.5 parts of foaming agent, 35 parts of calcium carbonate; each group of the upper fitting surface 2 The parts and parts by weight are as follows: 100 parts of PVC resin, 45 parts of plasticizer, 15 parts of color cake; the plasticizer is DOP dioctyl phthalate; the upper bonding surface 2 and the lower bonding surface 1 pass Hot pressing butt jointing; the upper butt joint groove is provided on the lower side of the upper joint surface 2; the lower butt joint groove is provided on the upper side of the lower joint surface 1; the upper butt joint groove and the lo...

Embodiment 3

[0039] Such as figure 1 and 2 As shown, a new type of decorative leather based on ramie fiber powder, including upper fitting surface 2, lower fitting surface 1, anti-corrosion ring body 3, ramie fiber powder body 5; anti-corrosion ring body 3 can be polytetrafluoroethylene material Made; each component of described lower fitting surface 1 and parts by weight are as follows: 100 parts of PVC resins, 5 parts of stabilizers, 4 parts of foaming agents, 40 parts of calcium carbonate; each group of described upper fitting surfaces 2 The parts and parts by weight are as follows: 100 parts of PVC resin, 50 parts of plasticizer, 20 parts of color cake; the plasticizer is DOP dioctyl phthalate; the upper bonding surface 2 and the lower bonding surface 1 pass Hot pressing butt jointing; the upper butt joint groove is provided on the lower side of the upper joint surface 2; the lower butt joint groove is provided on the upper side of the lower joint surface 1; the upper butt joint groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com