Cabinet for roll-to-roll conveying selective electroplating flexible printed circuit board and manufacturing process of cabinet

A flexible circuit board, selective technology, applied in the process of high current and insoluble anodic plating on flexible circuit boards, using roll-to-roll transport of flexible circuit boards, it can solve the problem of uneven coating thickness, multiple Problems such as potion cost and air bubbles in layout time, to achieve the effect of reducing layout time and potion cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] In order to make the technical problems, technical solutions and advantages to be solved by the embodiments of the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

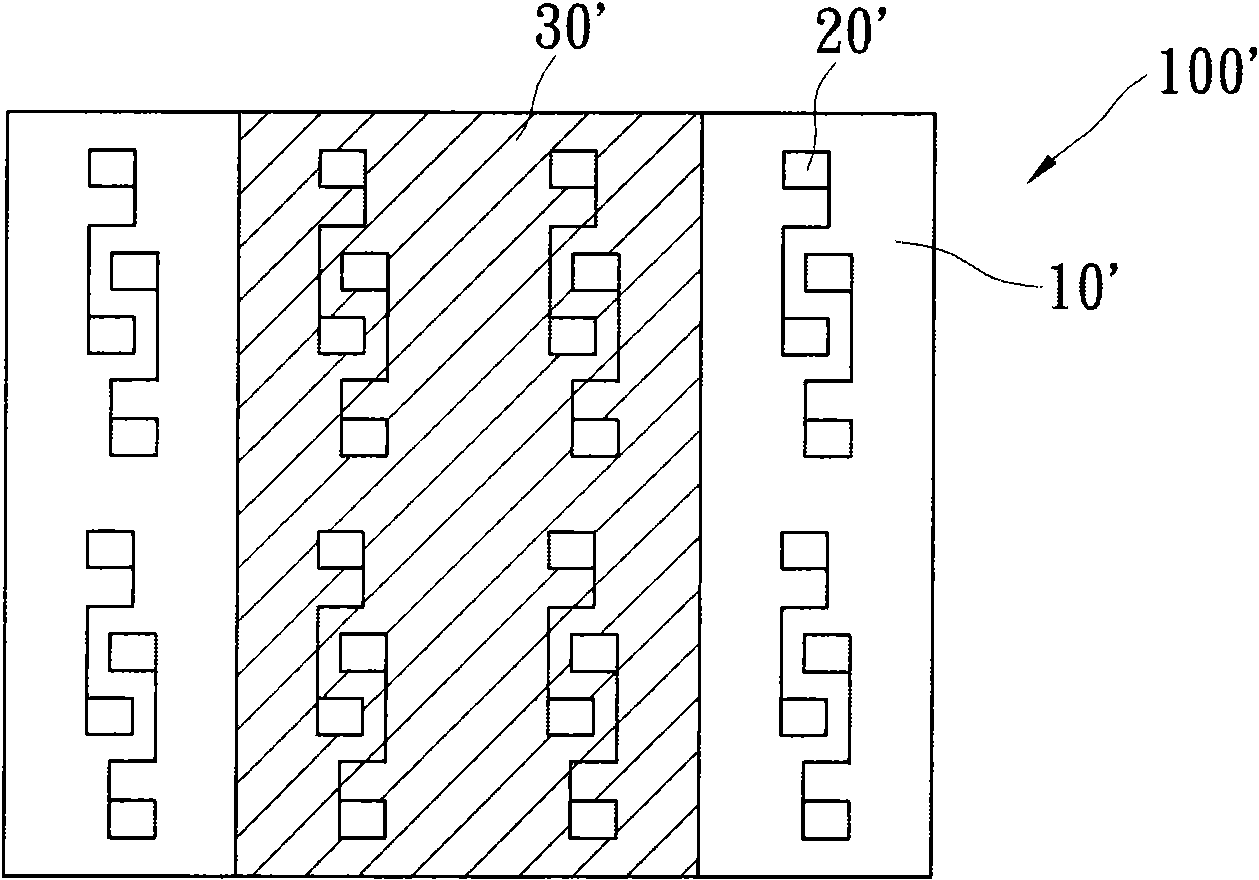

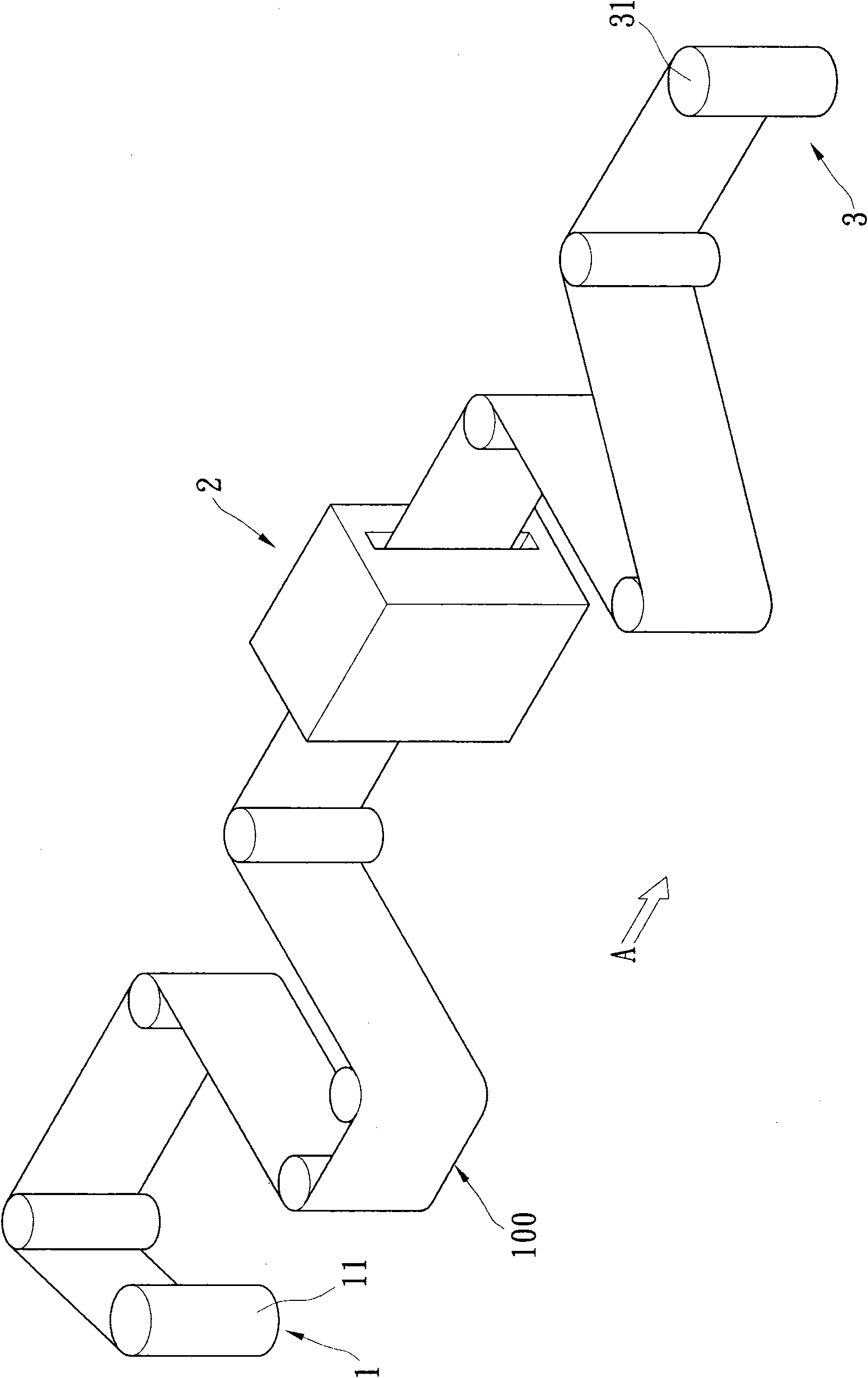

[0072] see figure 2 , figure 2 It is a three-dimensional schematic diagram of a preferred embodiment of the roll-to-roll conveying machine and process for selective electroplating of flexible circuit boards according to the present invention. The invention provides a machine for roll-to-roll delivery of selective electroplating flexible circuit boards, including a feeding reel machine 1 , a rewinding reel machine 3 and an electroplating device 2 . The feed reel machine 1 has a feed reel 11 . The reel machine 3 has a reel 31 , wherein a conveying path A for vertically transporting a flexible circuit board 100 is formed between the reel machine 1 and the reel machine 3 .

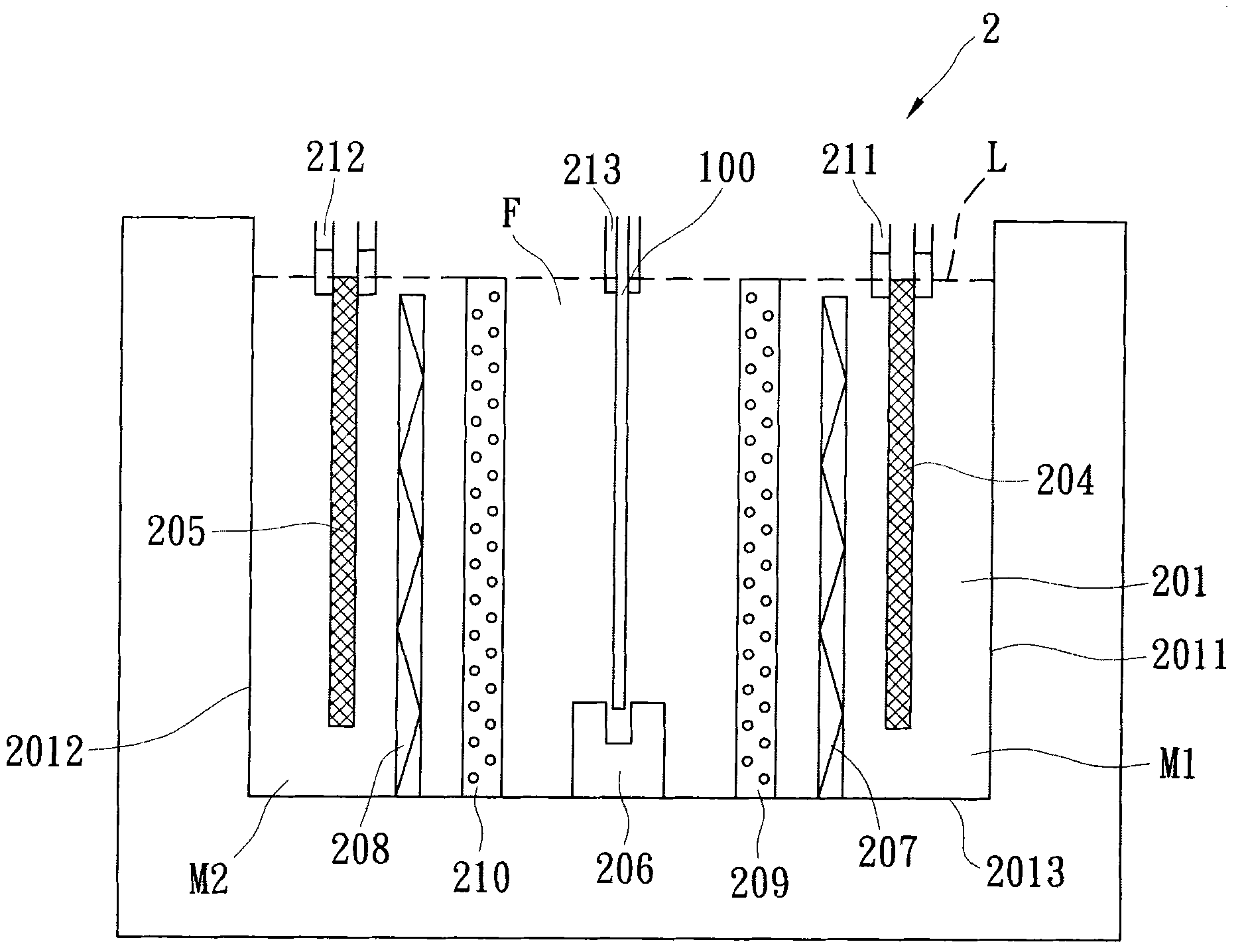

[0073] see image 3 as shown, image 3 It is a cross-section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com