Multi-specification tandem vibratory roller

A vibratory roller and double-drum technology, which is applied in the field of construction machinery, can solve the problems of affecting flatness and compaction, large equipment occupancy, increased transportation, operation and other costs and other issues, so as to maximize equipment efficiency and reduce equipment occupancy. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

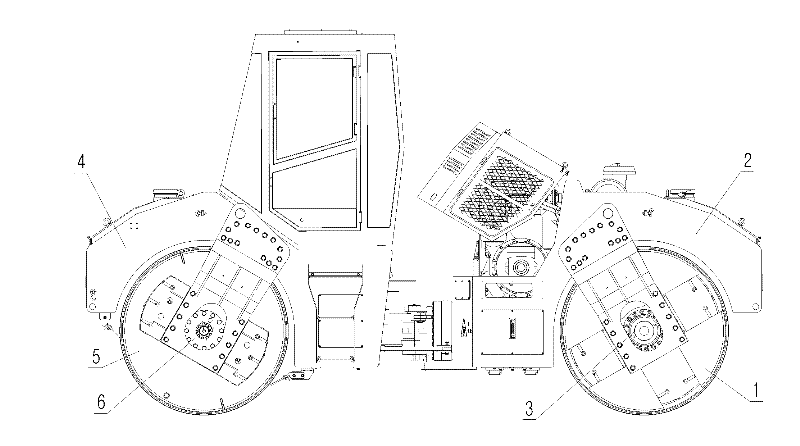

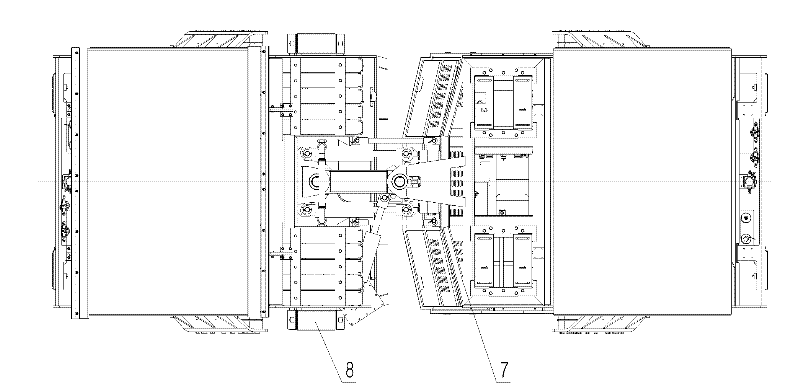

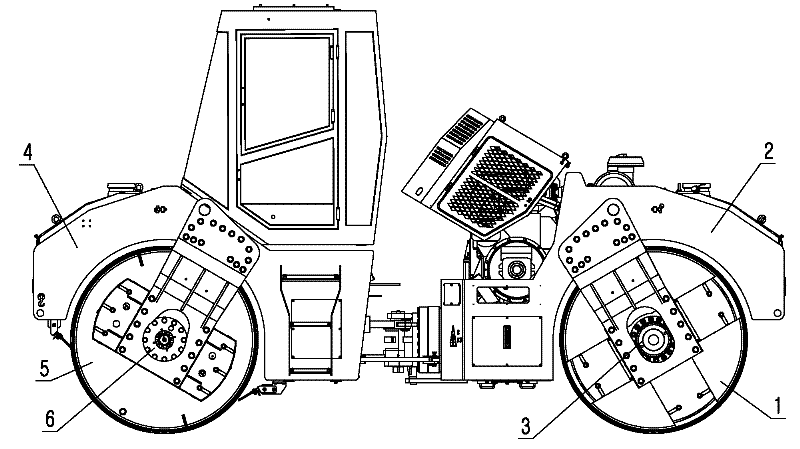

[0017] Such as figure 1 and figure 2 A kind of multi-standard double-drum vibratory road roller shown includes a front frame 4 and a rear frame 2 connected with the front frame 4, a front vibration wheel 5 is arranged below the front frame 4, and the rear frame 2, a rear vibrating wheel 1 is arranged below, a detachable front frame counterweight 8 is installed on the bottom of the front frame 4 through a card slot, and a detachable rear machine counterweight 8 is installed on the bottom of the rear frame 2 through a card slot. Frame counterweight 7, front vibrating wheel counterweight 6 is installed on the described front vibrating wheel 5, rear vibrating wheel counterweight 3 is installed on the described rear vibrating wheel 1. The front frame counterweight 8 is made up of a water tank and a plurality of detachable counterweights. Described rear frame counterweight 7 is made up of a water tank and a plurality of detachable counterweights. The front vibrating wheel counte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com