Preparation method of film

A production method and film technology, which is applied to the photoengraving process, instruments, optics and other directions of the pattern surface, can solve the problems such as the texture effect of the final product, the deviation of the pattern and the sample pattern that affect the process accuracy, and achieve high authenticity and accuracy. Sexuality, clear lines, and the effect of no manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Step 1. Cleaning: wash and dry the fabric sample with three-dimensional pattern;

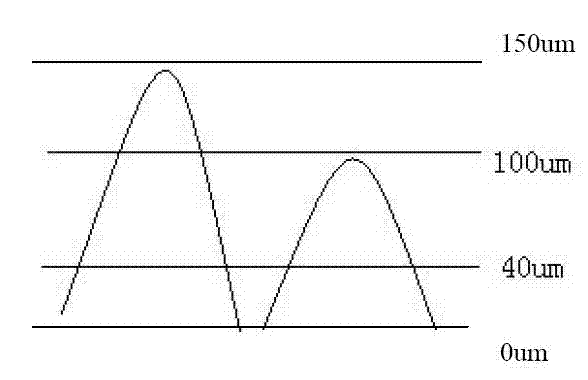

[0046] Step 2. Line scanning: use a probe-type measuring instrument to perform line scanning along one side of the fabric to the other side, and obtain the following: figure 1 The graph shown. figure 1 The curve shown in is only part of the fabric sample, including curve A1 and curve A2, where the lowest valley in the curve is used as a reference, counted as 0um, the peak height of curve A1 is higher than 100um, and the peak height of curve A2 is low Therefore, the texture of the template can be divided into two levels, below 100um and above 100um. According to the line scan data, it is necessary to perform layered cutting within the height range of 0-150um. In order to better express the difference in texture height, it is necessary to cut one layer above and below 100um; confirm the cutting according to the line scan results Cutting standard, cutting in two layers, the cutting height ...

Embodiment 2

[0052] Step 1. Cleaning: Thoroughly clean the skin texture sample with alcohol to ensure the cleanliness of the surface;

[0053] Step 2. Line scanning: Use a roughness profiler (produced by Hommel, Germany, model T1000) to scan the surface profile along the middle position of the skin texture sample, and get the following: Figure 4 The graph shown. According to the distribution state of the curves in the graph, the texture fluctuation of the dermatoglyph sample is analyzed, and it is considered that the height range of the texture is between 0um-50um, and based on the distribution density of the curve, it is mainly bounded by 12.5um and 25um ( like Figure 4 Center line 1 and line 2), which are divided into three levels, and the curve distribution in the range of 12.5um-25um is the most dense; in order to better reflect the texture undulation, three layers of 12.5um, 25um and 37.5um are selected as the cutting standard ( Preferably, 10um, 20um, and 40um can also be selecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com