Surface inspection device for cylindrical body

A technology for surface inspection devices and cylinders, which is applied to measuring devices, instruments, scientific instruments, etc., can solve the problems of decreased inspection accuracy and inability to correctly distinguish undefective strip-shaped recesses Da, etc., so as to improve inspection accuracy and reduce Dimensions, effects of high inspection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

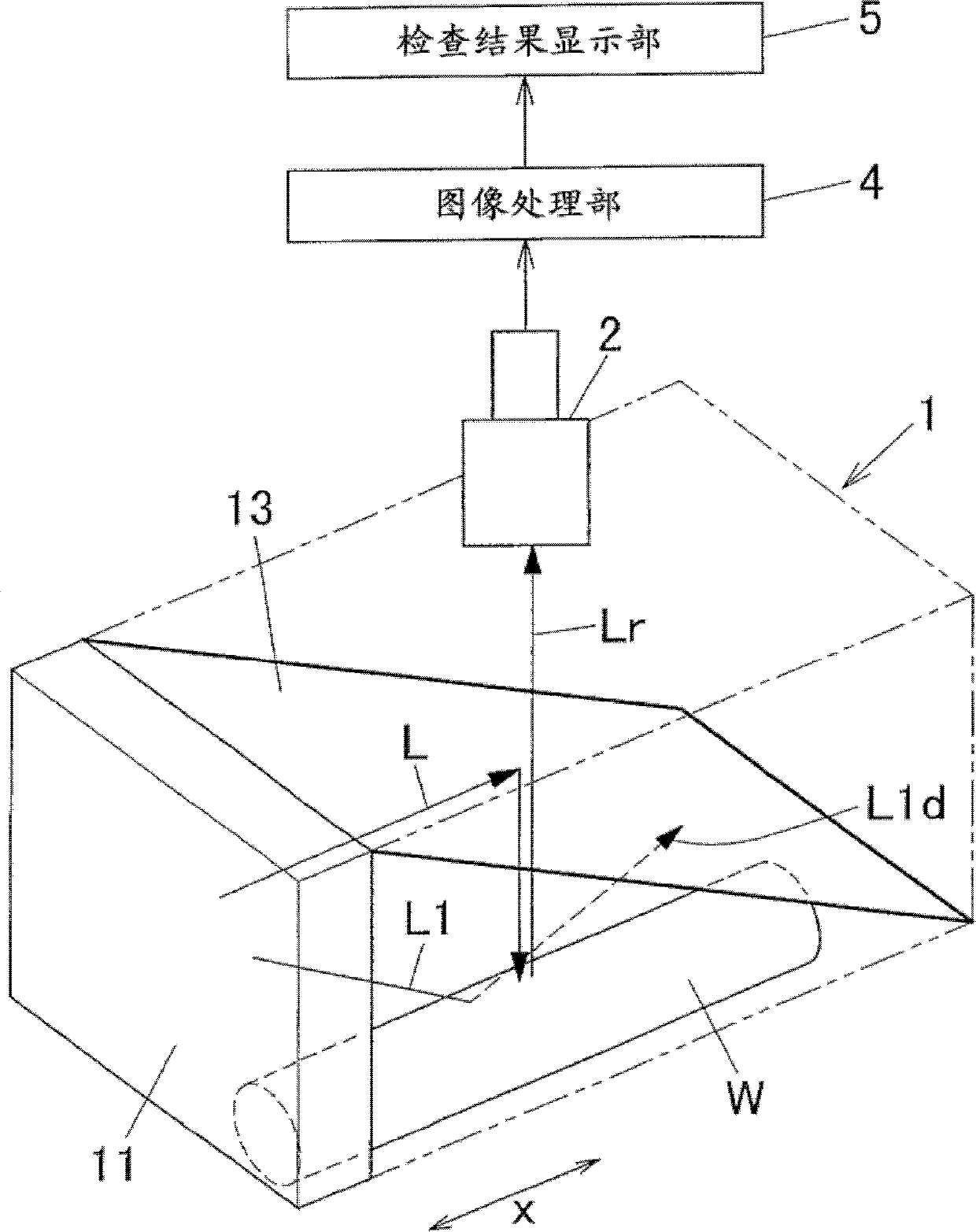

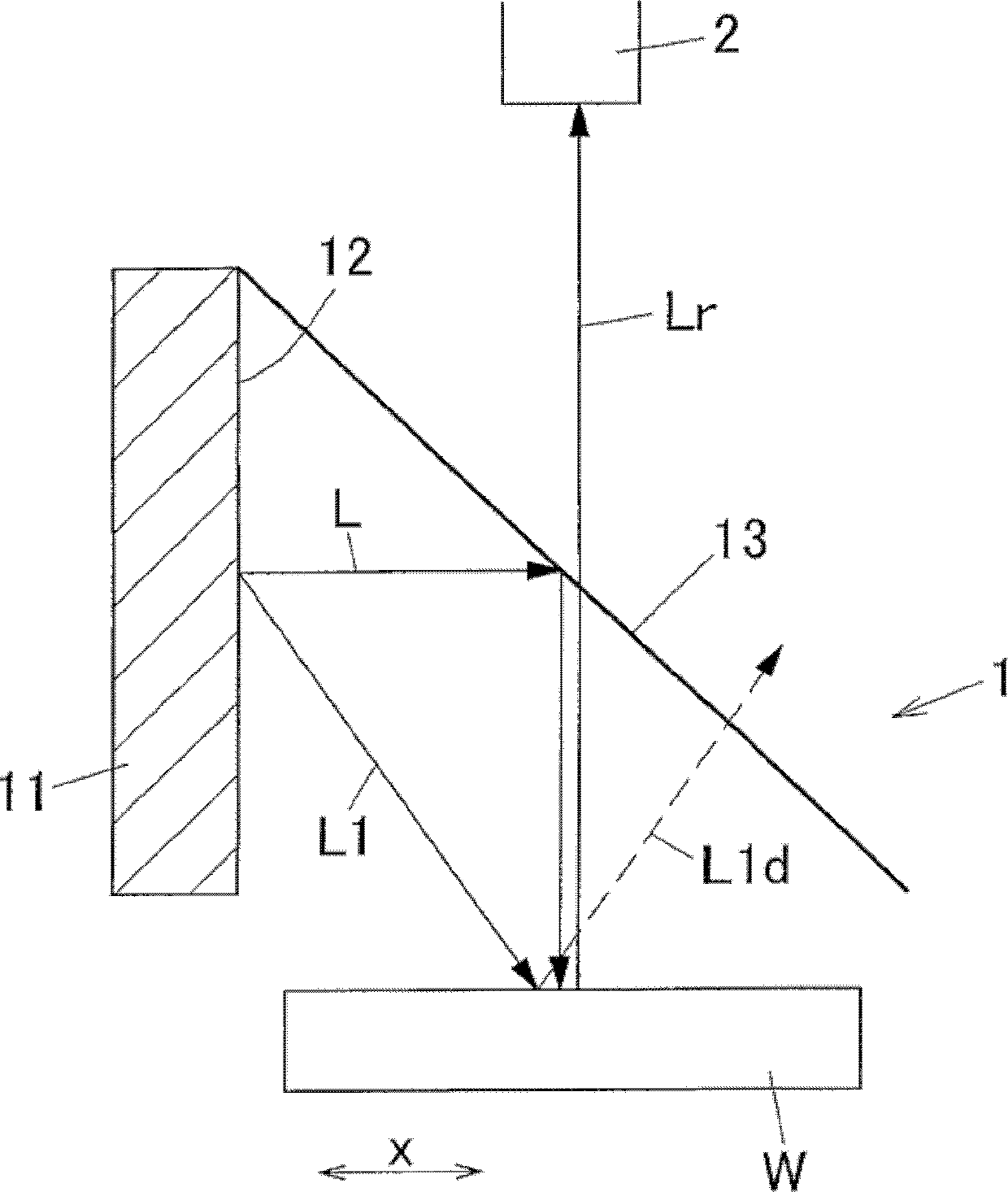

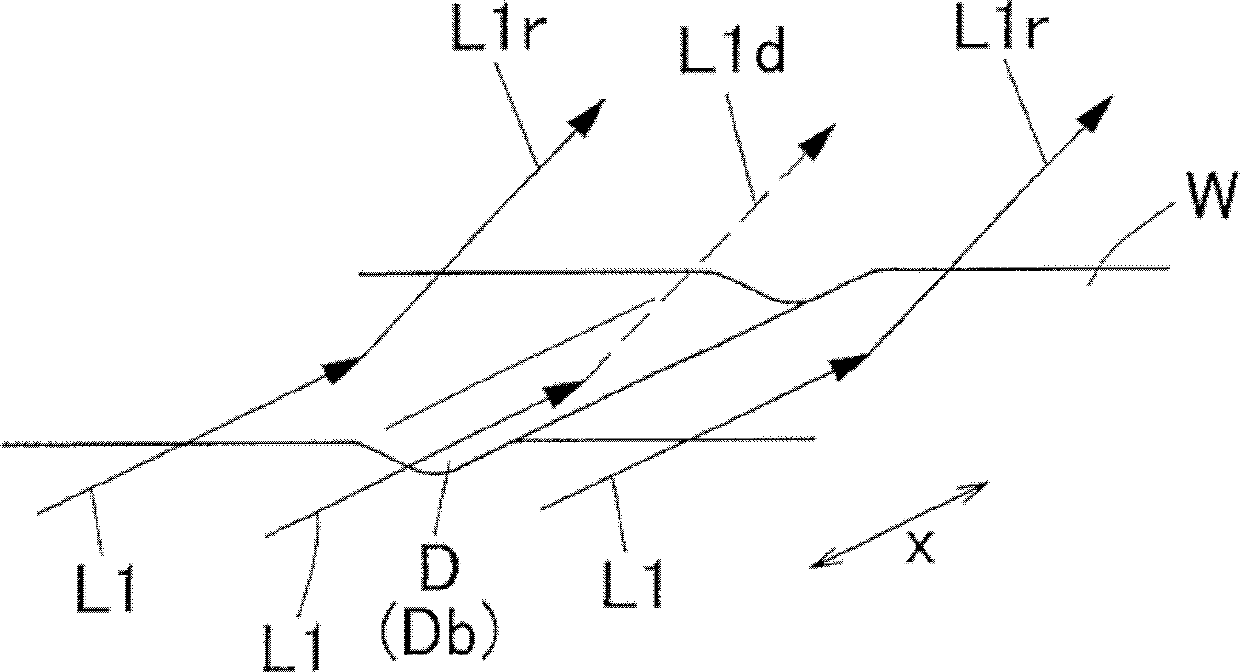

[0057] figure 1 , 2 It is a figure which shows the surface inspection apparatus of the cylindrical body which is embodiment of this invention. As shown in both figures, this surface inspection device can inspect the surface of a cylindrical body W as an inspection object (work).

[0058] The cylindrical body W is used for photosensitive drums, transfer rollers, developing rollers, and other components in, for example, copiers, printers, facsimile machines, and multifunction machines constituting an electrophotographic system.

[0059] Among the cylindrical body W that can constitute such a member, a cylindrical body W used as a raw material tube and / or a substrate for a photosensitive drum in a copier and / or a printer can be cited as a preferred example in the embodiment. Copiers and / or printers that employ an electronic photo system. In addition, the substrate for a photosensitive drum refers to a tube body before forming a photosensitive layer after cutting and / or drawin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com