Electronic part and method of detecting faults therein

A technology of electronic components and fault detection, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve problems such as miniaturization of difficult electronic components 501

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

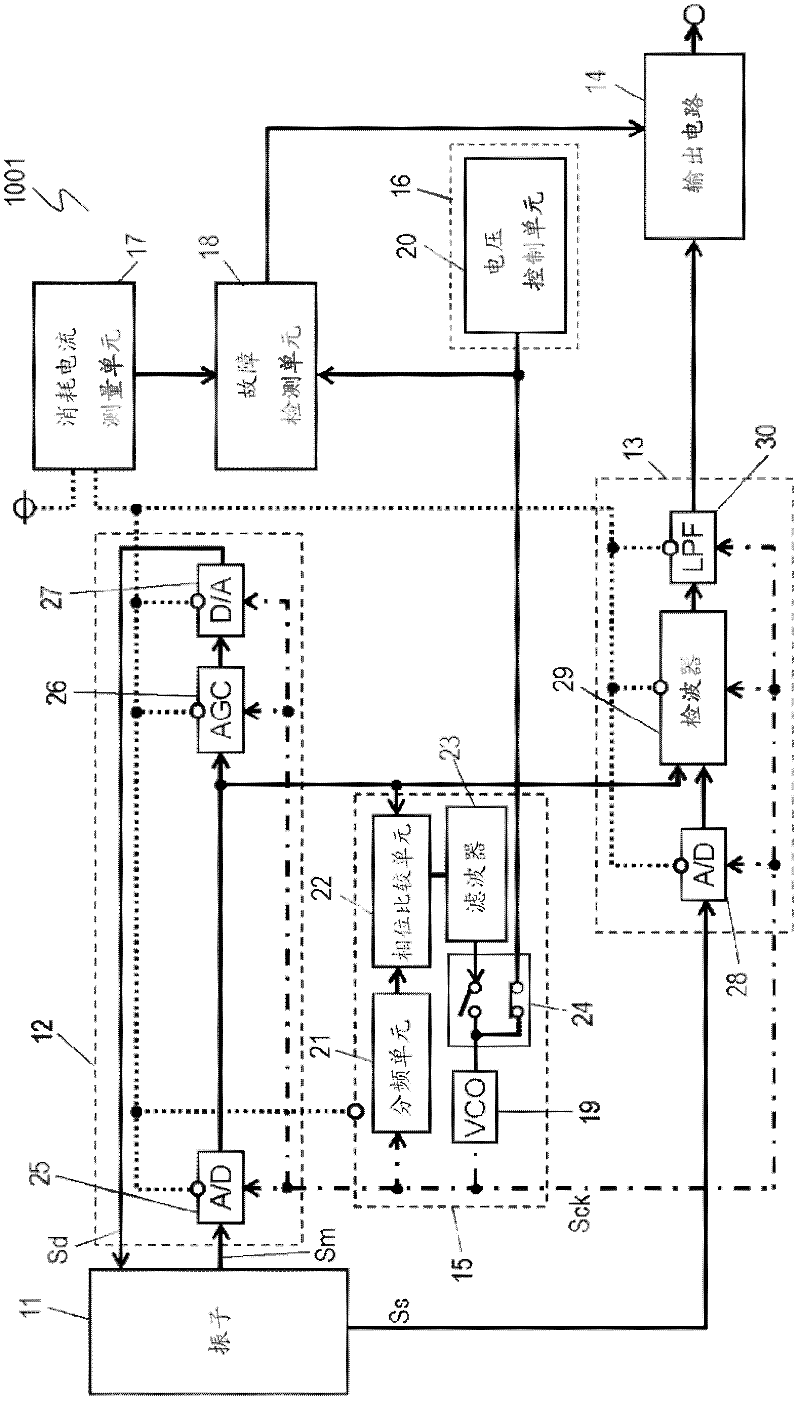

[0026] figure 1 It is a circuit diagram of the electronic component 1001 in Embodiment 1 of this invention. The electronic component 1001 includes: a vibrator 11; a drive circuit 12 that supplies a drive signal Sd to the vibrator 11; a detection signal processing unit 13 that inputs an induction signal Ss from the vibrator 11; an output circuit that outputs an induction signal output from the detection signal processing unit 13 14; the clock frequency generation unit 15 of the output clock signal Sck; the clock frequency control unit 16 of the frequency of the control clock signal Sck; the consumption current measurement unit 17 of the consumption current of the detection drive circuit 12 and the detection signal processing unit 13; and electrically connected to Consumption current measurement unit 17 and failure detection unit 18 of clock frequency control unit 16 . The clock frequency generation unit 15 outputs a clock signal Sck to some of the drive circuit 12 and the det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com