Silencing device for dust collector

A technology for noise reduction devices and vacuum cleaners, which is applied in the direction of noise reduction devices, vacuum cleaners, machines/engines, etc. It can solve the problems of increasing the tortuousness of the air duct, poor noise reduction and noise reduction effects, etc., and achieve good noise reduction effects and noise reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

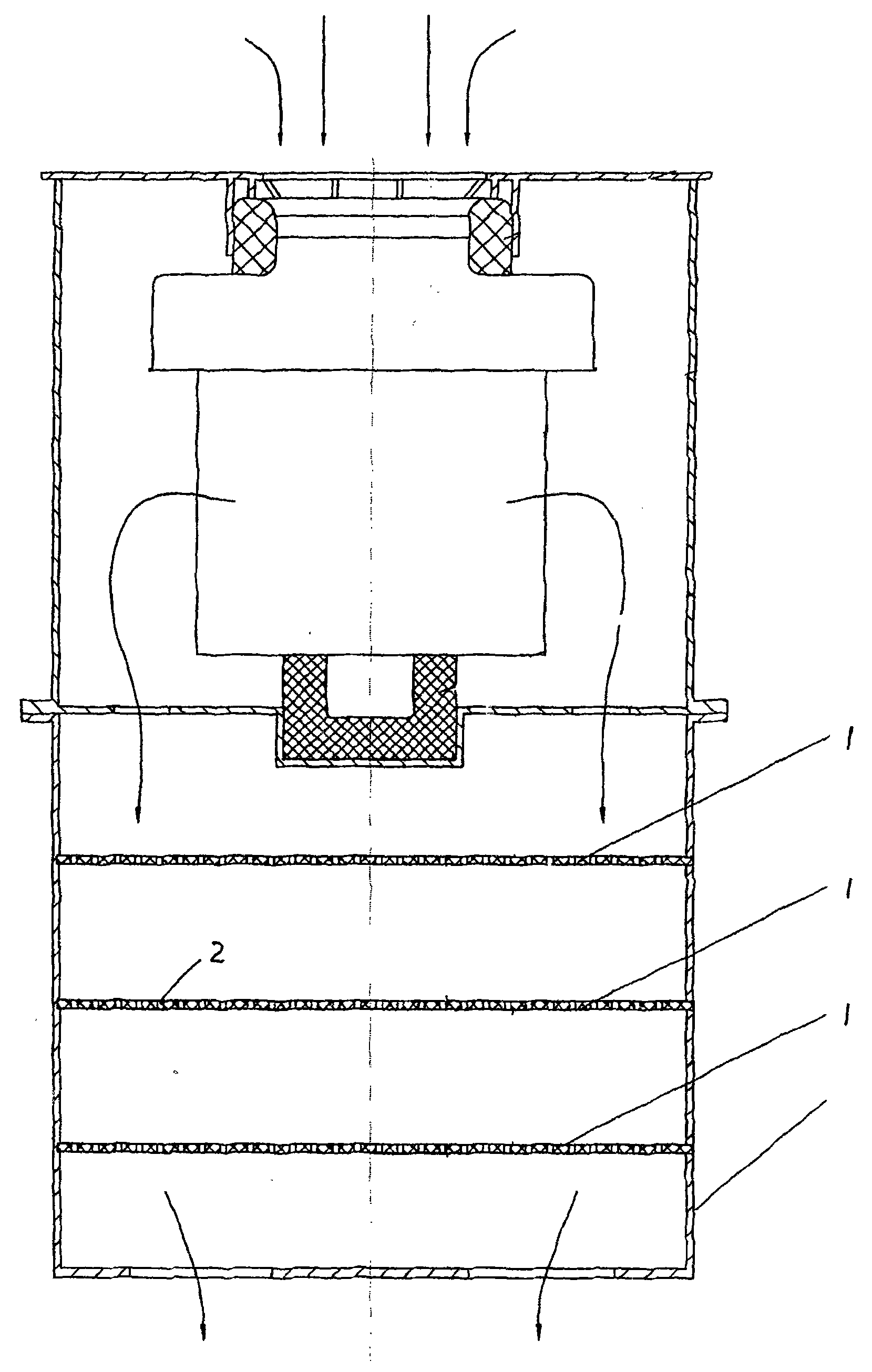

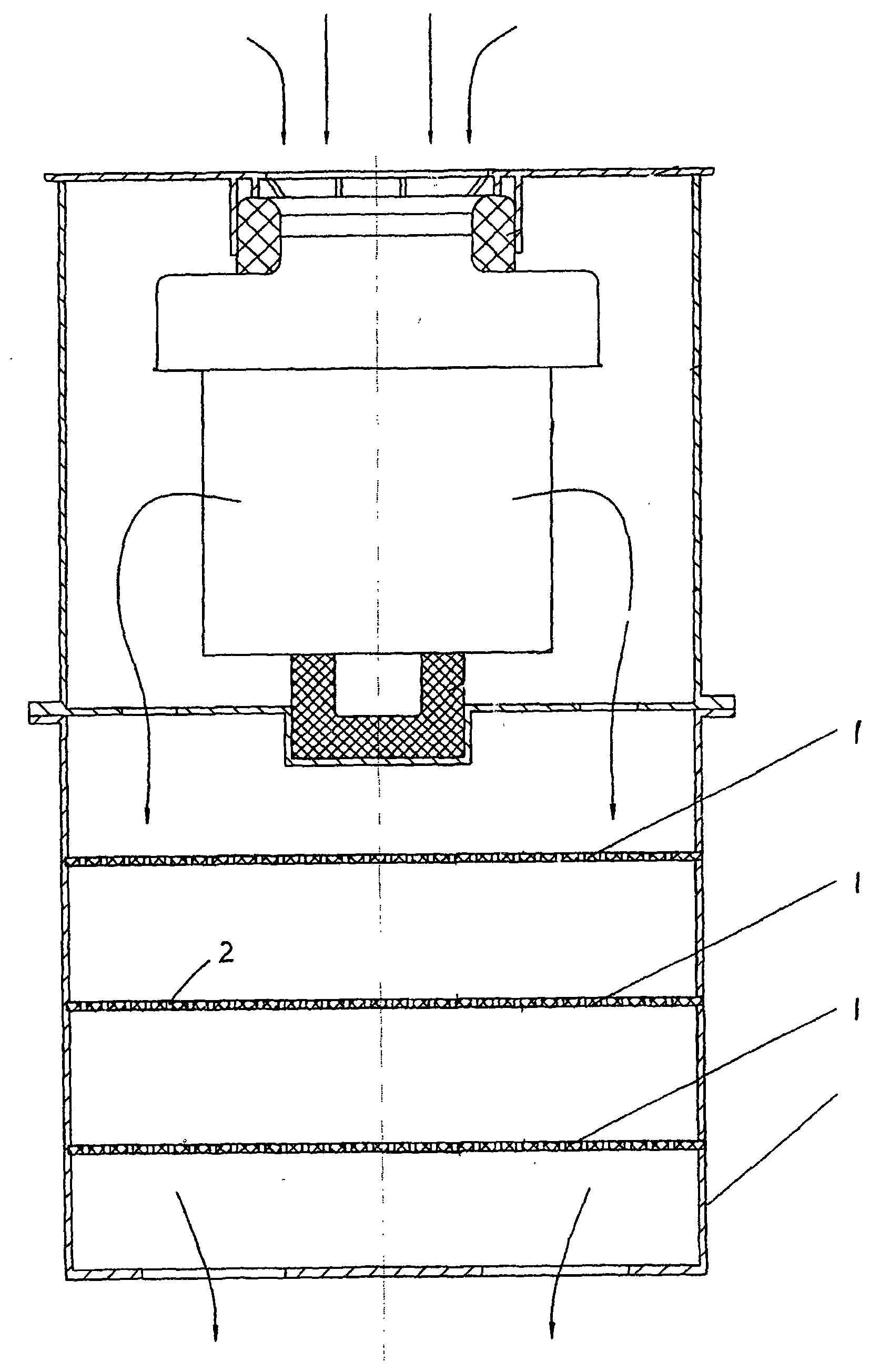

[0013] Embodiment: As shown in Fig. 1, a kind of sound-absorbing device for vacuum cleaner, this device comprises three sound-absorbing baffles (1) installed in the air outlet channel (3), and the sound-absorbing baffles (1) are covered with small holes ( 2), the sound-absorbing partition (1) is perpendicular to the airflow direction in the air outlet channel (3), and the total ventilation area of the small holes (2) of the sound-absorbing partition (1) is less than 0.5 of the cross-sectional area of the air outlet channel (3). times, the diameter of the small hole (2) on the sound-absorbing partition (1) is less than 6 mm, and the thickness of the sound-absorbing partition (1) is greater than 0.5 mm.

[0014] The use of one or more sound-absorbing partitions (1) installed in the air outlet channel (3) can greatly reduce the noise emitted by the vacuum cleaner during use; the sound-absorbing partition (1) of the present invention can be installed separately in the air outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com