Method for controlling a hybrid drive train of a vehicle

一种动力系统、控制方法的技术,应用在混合动力车辆、道路车辆驱动控制系统、传动装置控制等方向,能够解决降低行驶舒适感等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

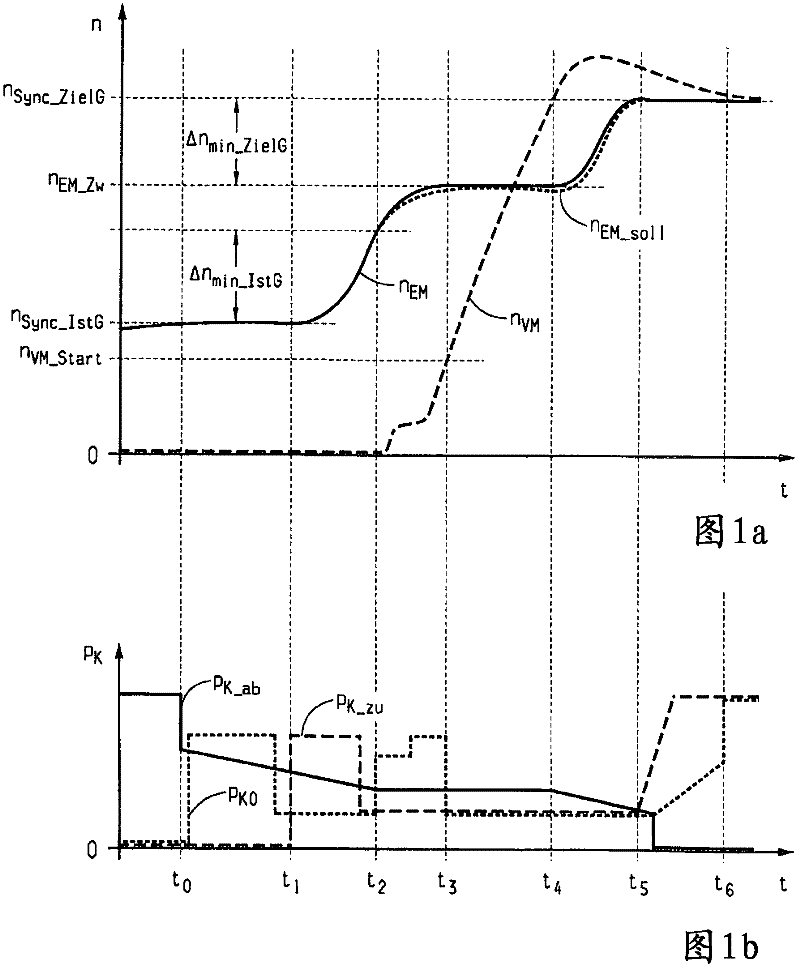

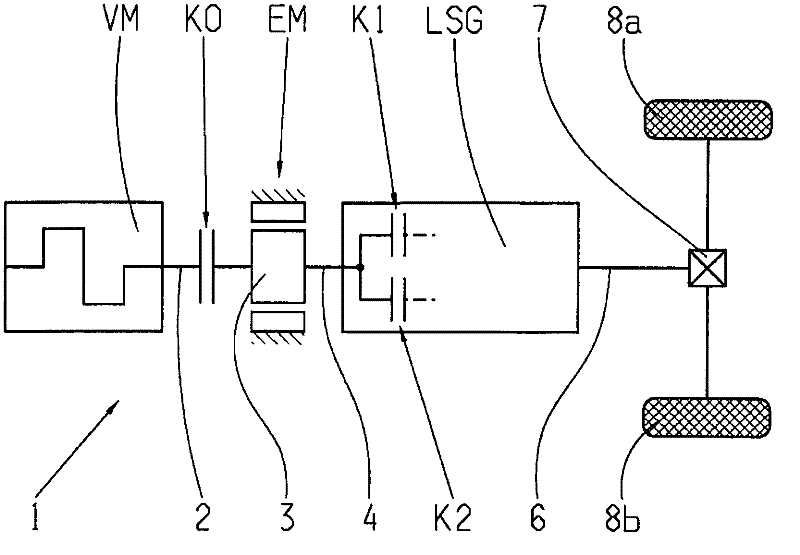

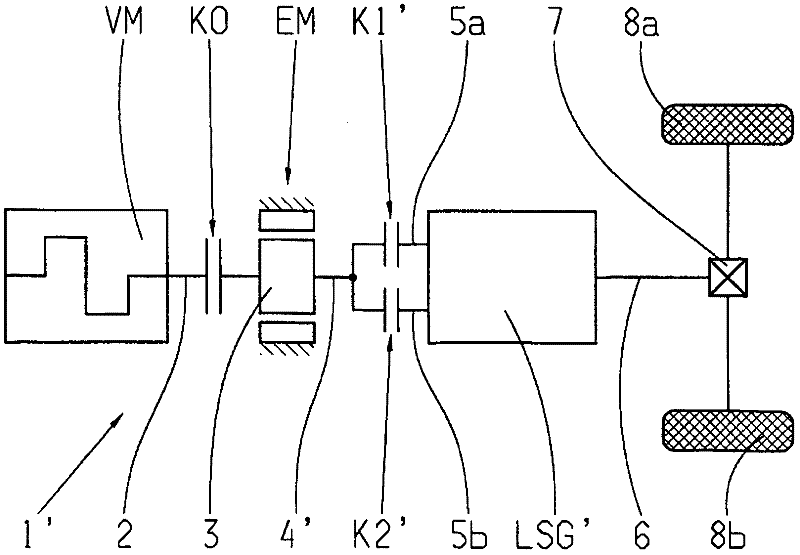

[0030] exist Figure 2a and Figure 2b A hybrid power system 1 , 1 ′ working in parallel is schematically shown in FIG. 1 , and the control method according to the present invention can be applied to the hybrid power system. The two embodiments of the hybrid drive system 1, 1' each comprise: an internal combustion engine VM equipped with a drive shaft 2; an electric machine EM operable at least as a motor and equipped with a rotor 3; and a powershift transmission LSG , LSG'. The rotors 3 of the electric machine EM can be connected to and decoupled from the drive shaft 2 of the internal combustion engine VM via an automated separating clutch K0, so that the internal combustion engine can, if necessary, be started via the electric machine EM, coupled to it and Disconnect the motor. The rotor 3 of the electric machine EM is connected on the output side to an input element 4 , 4 ′ of a powershift transmission LSG, LSG′, respectively.

[0031] in press Figure 2a In the illust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com