Device and method for measuring thickness of zinc layer in continuous hot galvanizing machine set

A technology of hot-dip galvanizing and zinc coating, applied in hot-dip galvanizing process, coating, metal material coating process, etc., can solve the problems of precise control, lag and inability to zinc coating weight, etc., to achieve precise control and reduce energy consumption and production costs, the effect of eliminating hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The device and method for measuring the thickness of the zinc layer of the present invention will be described in more detail below with reference to the accompanying drawings and specific embodiments.

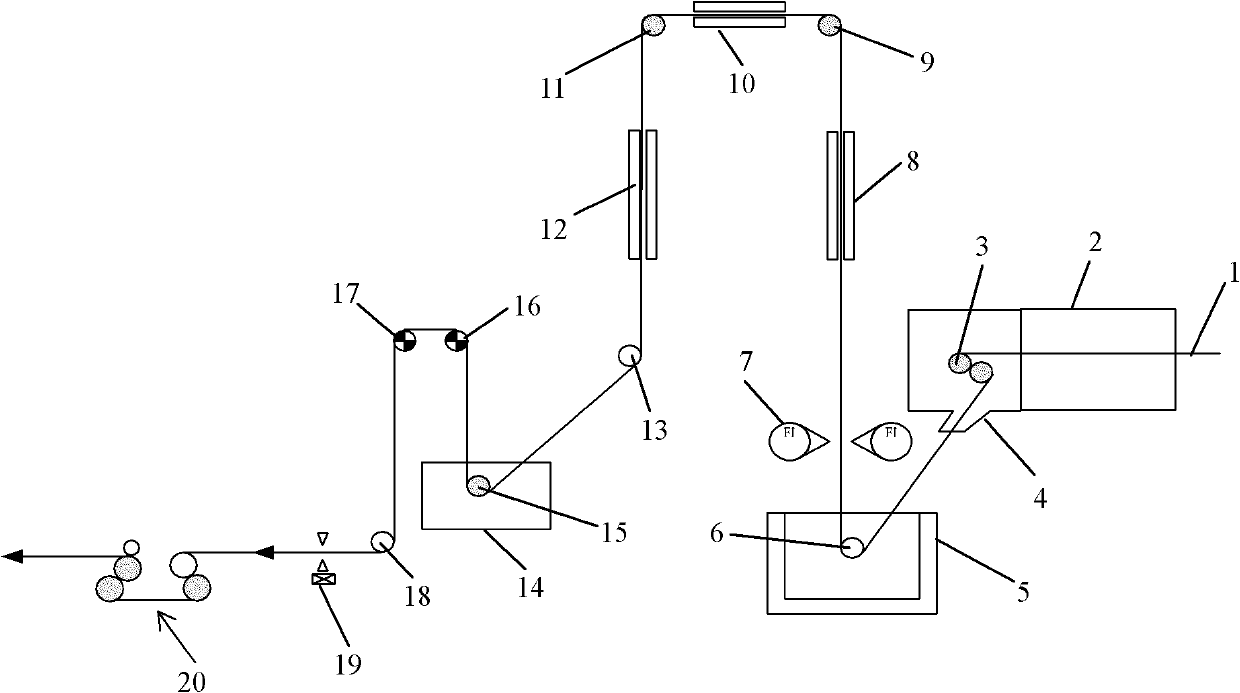

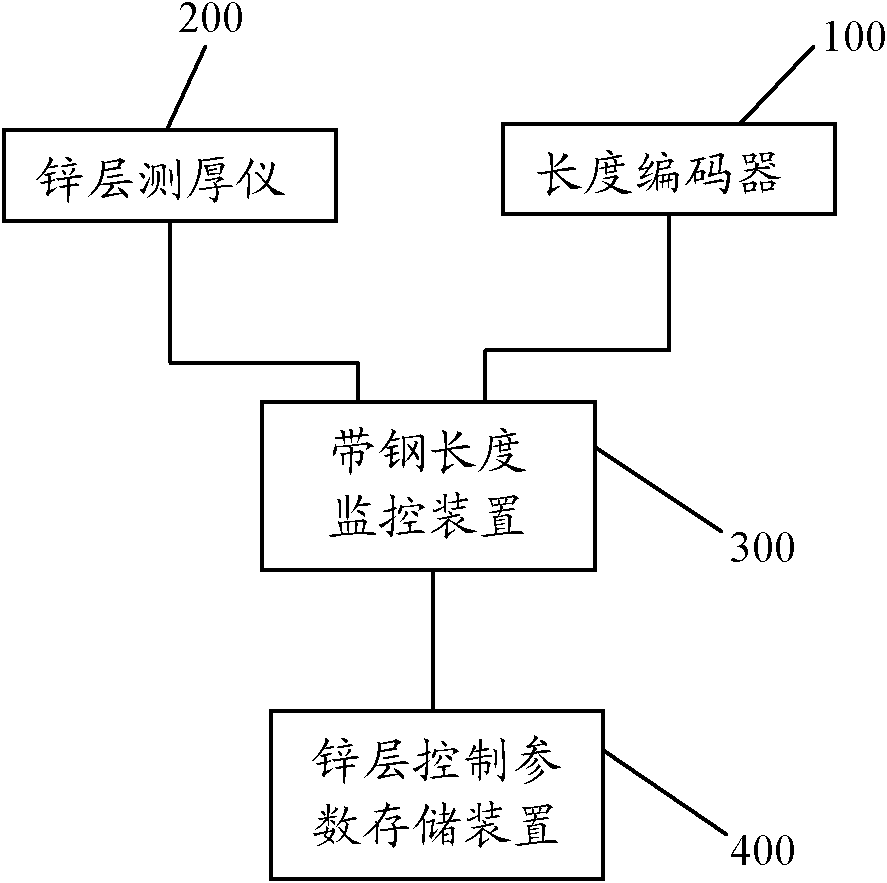

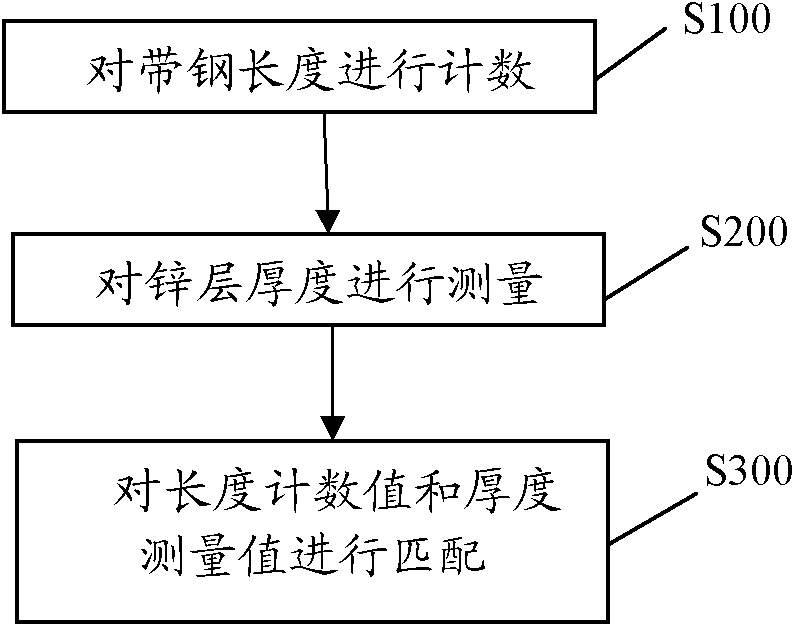

[0030] Such as figure 2 Shown is a schematic diagram of the device for measuring the thickness of the zinc layer of the present invention used in the galvanizing line. The measuring device includes a length encoder 100 , a zinc layer thickness gauge 200 , a strip length monitoring device 300 and a zinc layer control parameter storage device 400 . to combine figure 1 , wherein the length encoder 100 is arranged on the tension roller 20 for counting the length of the steel strip; the zinc layer thickness gauge 200 is arranged after the turning roller 18 for the thickness of the zinc layer (that is, the Layer weight) for measurement; the strip length monitoring device 300 is connected with the length encoder 100 and the zinc layer thickness gauge 200 respectively; the z...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com