A hot-dip galvanizing process and hot-dip galvanizing system for iron tower components

A technology of hot-dip galvanizing and hot-dip galvanizing, applied in hot-dip galvanizing process, metal material coating process, coating and other directions, can solve the problem of decreased anti-corrosion performance, difficult to control the quality of galvanized, and substandard quality of galvanized products and other problems, to achieve the effect of fast melting, ensuring the quality of galvanizing, and improving the galvanizing index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

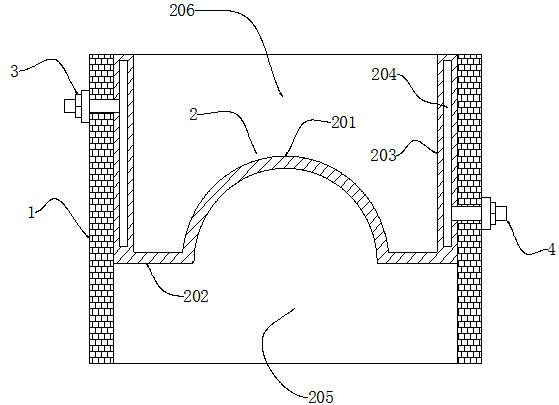

Embodiment Construction

[0046] The technical solution of the present invention will be further described in detail below in conjunction with specific examples, but the protection scope of the present invention is not limited to the following description.

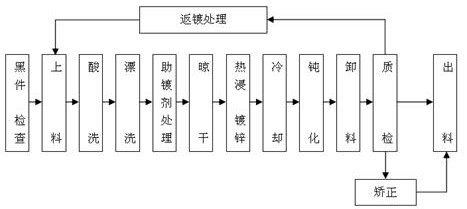

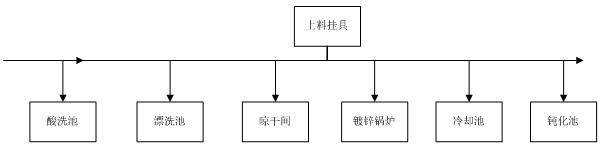

[0047] A hot-dip galvanizing process for iron tower components, the process comprising:

[0048] S100: Black parts inspection, inspect the galvanized parts that need to be hot-dip galvanized, and those that do not meet the galvanizing conditions are not allowed to enter the galvanizing production line;

[0049] S200: pickling during loading, pickling the plated parts that meet the galvanizing conditions with pickling solution;

[0050] S300: Rinse and dry. Plated parts that have passed the pickling process enter the rinsing process tank and are rinsed with running water to remove the residual acid solution on the surface. The time of staying in the tank is not less than 15 seconds. Soak the tank with plating flux for 0.5-2.0 minutes, and then dry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Adhesion amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com